A railway freight car

A technology for railway freight and carriages, which is applied in the loading and unloading of railway car body parts, freight cars, and railway vehicles, etc., can solve the problems of unloadable container units, low standardization, and low reliability, so as to improve the efficiency of cargo loading and unloading. Application prospects, the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

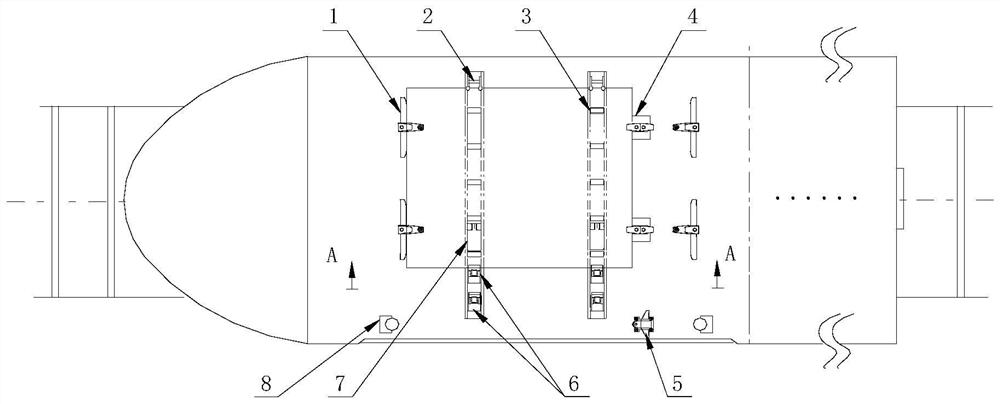

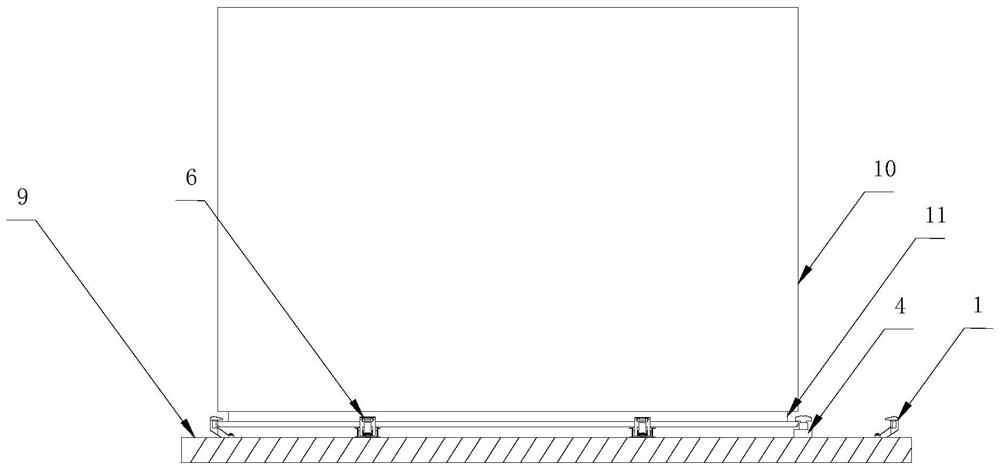

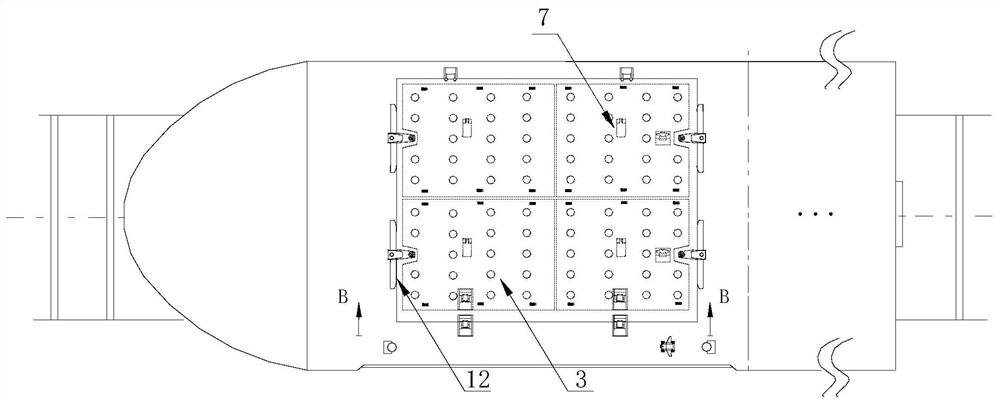

[0037] The railway freight carriage provided by the present invention is illustrated below in conjunction with the accompanying drawings.

[0038] figure 1 It is a structural schematic diagram of a railway freight car provided by an embodiment of the present invention, figure 2 yes figure 1 The cross-sectional view of A-A, such as figure 1 and 2 As shown, the railway freight car is provided with multiple loading positions, and each loading position is provided with a set of loading and unloading devices, and each set of loading and unloading devices includes: side rail 1, end stop device 2, transmission device 3, automatic Reset type stop lock 4, movable guide column 5, one-way stop lock 6, power drive device 7 and fixed guide column 8;

[0039] The bottom surface of the container unit should be flat, which has a card slot that can be used in conjunction with the container loading and unloading device.

[0040] The side rails 1 are located at the front and rear of each l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com