Sewage treatment system

A technology of sewage treatment system and sewage pool, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc. Operation and other problems, to avoid hindering the operation of equipment, reduce equipment costs and space, and facilitate collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

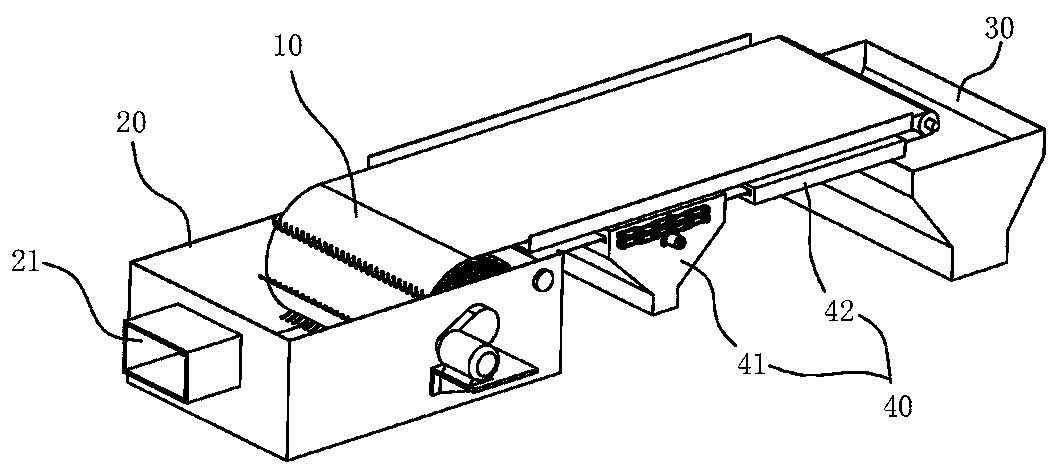

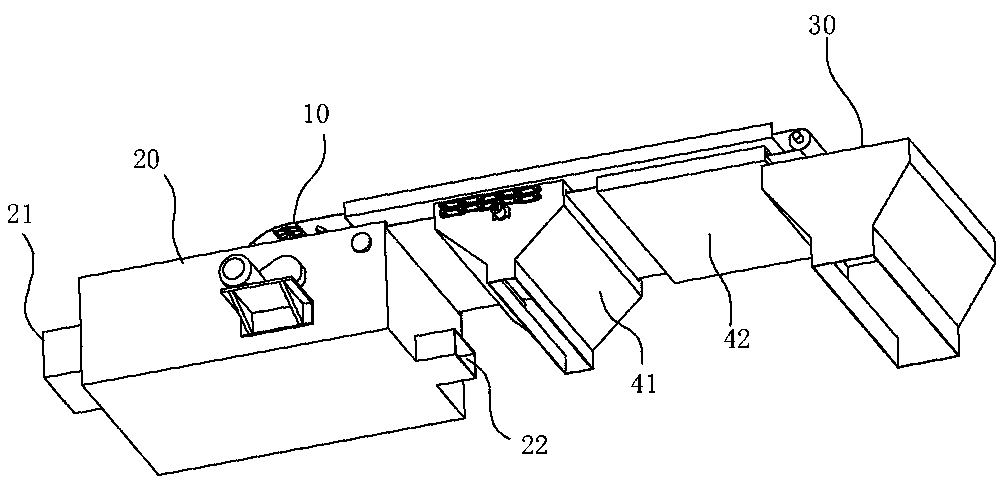

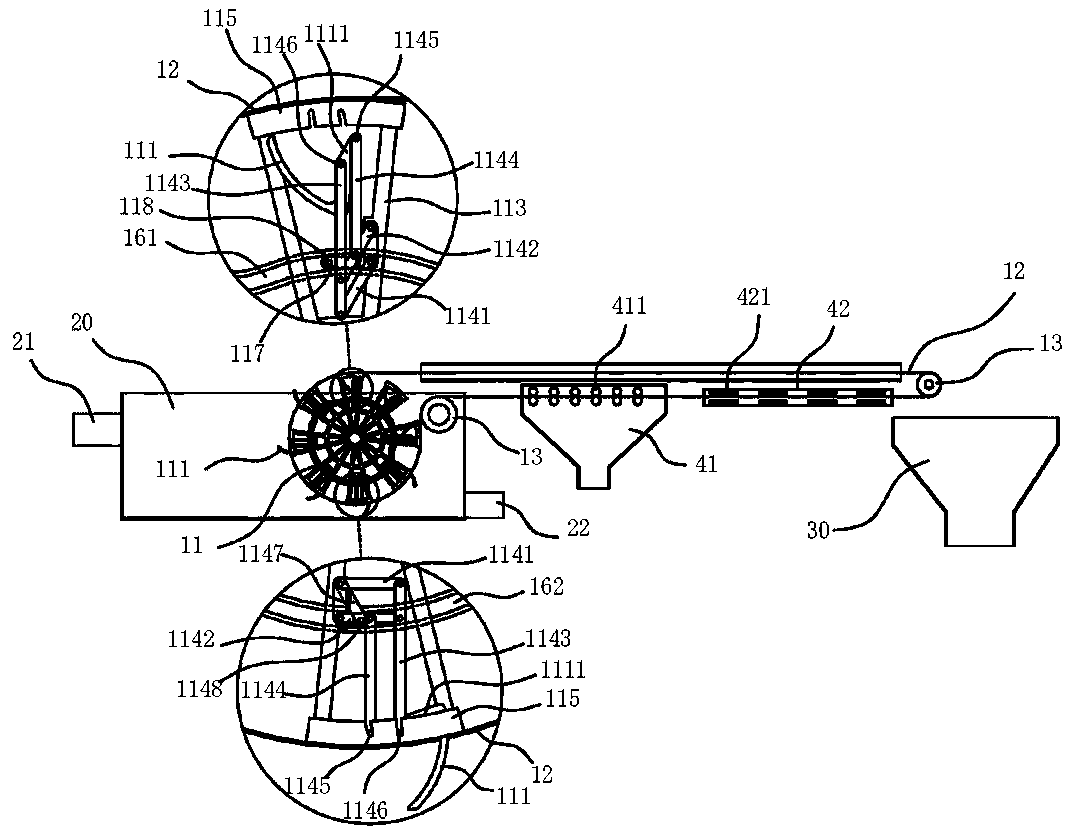

[0029] Such as Figure 11 Shown, a kind of sewage treatment system comprises solid-liquid separation device 1, anaerobic pond 2, anoxic pond 3, aerobic pond 4, sedimentation pond 5, disinfection pond 6 and outlet well 7; figure 1 , 2 , 3, the solid-liquid separation device 1 includes a sewage tank 20, a material transfer mechanism 10, a solid waste recovery mechanism 30 and a floc recovery mechanism 40; the sewage tank 20 is provided with a water inlet 21 and a water outlet 22 ;Such as Figure 4 As shown, the material transfer mechanism 10 includes a material transfer roller 11, a conveying mesh belt 12 and a guide roller 13; Immediately between the shifting roller 11 and the guide roller 13, the shifting roller 11 is provided with a movable hook 111, and the movable hook 111 is telescopically arranged on the roller surface of the shifting roller 11, and the movable hook 111 It is assembled to move between the following two stations: station one, the movable hook 111 protru...

Embodiment 2

[0037] A method for solid-liquid separation of sewage, comprising the steps of:

[0038] Step 1: discharge the mixed sewage with solid waste and floc into the sewage tank 20;

[0039] Step 2: filter the mixed sewage by using the material transfer mechanism 10, the material transfer mechanism 10 separates the solid waste and floc from the mixed sewage, and the filtered sewage enters the downstream reaction pool;

[0040] Step 3: the material transfer mechanism 10 transports the solid waste to the solid waste recovery mechanism 30, and the flocs are adsorbed on the conveying mesh belt 12 of the material transfer mechanism 10 and continue to be transported;

[0041] Step 4: The flocs enter the floc recovery mechanism 40 along with the conveyor belt 12, and the floc recovery mechanism 40 cleans the conveyor belt 12 and recovers the flocs adsorbed thereon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com