Flame retardant and method for preparing flame-retardant polyester by using flame retardant

A flame retardant polyester and flame retardant technology, applied in flame retardant fibers, fiber types, textiles and papermaking, etc., can solve problems such as melt drop disasters, burns, fires, etc., to save labor costs, simple operation, environmental protection low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1. Fabric pretreatment: In order to have good adhesion between the flame retardant additive and the polyester fabric, the polyester fabric must be clean and free of dirt, so the polyester fabric should be pretreated before flame retardant treatment. The pretreatment solution contains sodium hydroxide, penetrant and surfactant. Put the polyester fabric into an appropriate pretreatment solution, boil it at 90°C for 30 minutes, take it out, wash it with clean water, and dry it for later use.

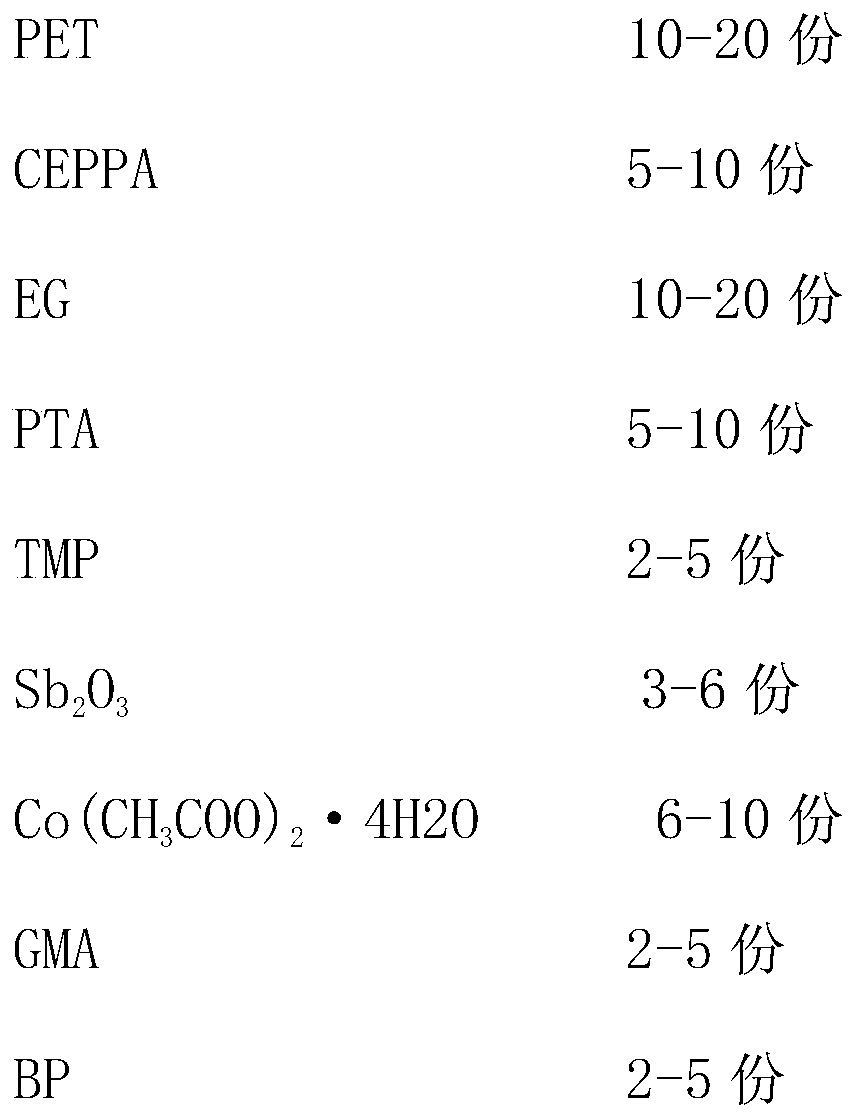

[0022] Step 2, preparation of flame retardant:

[0023]

[0024] Measure a certain amount of EG, and slightly excess. Add the materials into the reactor that has been washed, and react for 3 hours while maintaining the internal temperature at 150°C. Judge whether the pre-esterification is completed according to the amount of esterified water and the temperature at the top of the fractionating column; a certain amount of PTA, stabilizer TMP, toner Co(CH 3 COO) 2 4H2O, poly...

Embodiment 2

[0032] Step 1. Fabric pretreatment: In order to have good adhesion between the flame retardant additive and the polyester fabric, the polyester fabric must be clean and free of dirt, so the polyester fabric should be pretreated before flame retardant treatment. The pretreatment solution contains sodium hydroxide, penetrant and surfactant. Put the polyester fabric into an appropriate pretreatment solution, boil it at 90°C for 30 minutes, take it out, wash it with clean water, and dry it for later use.

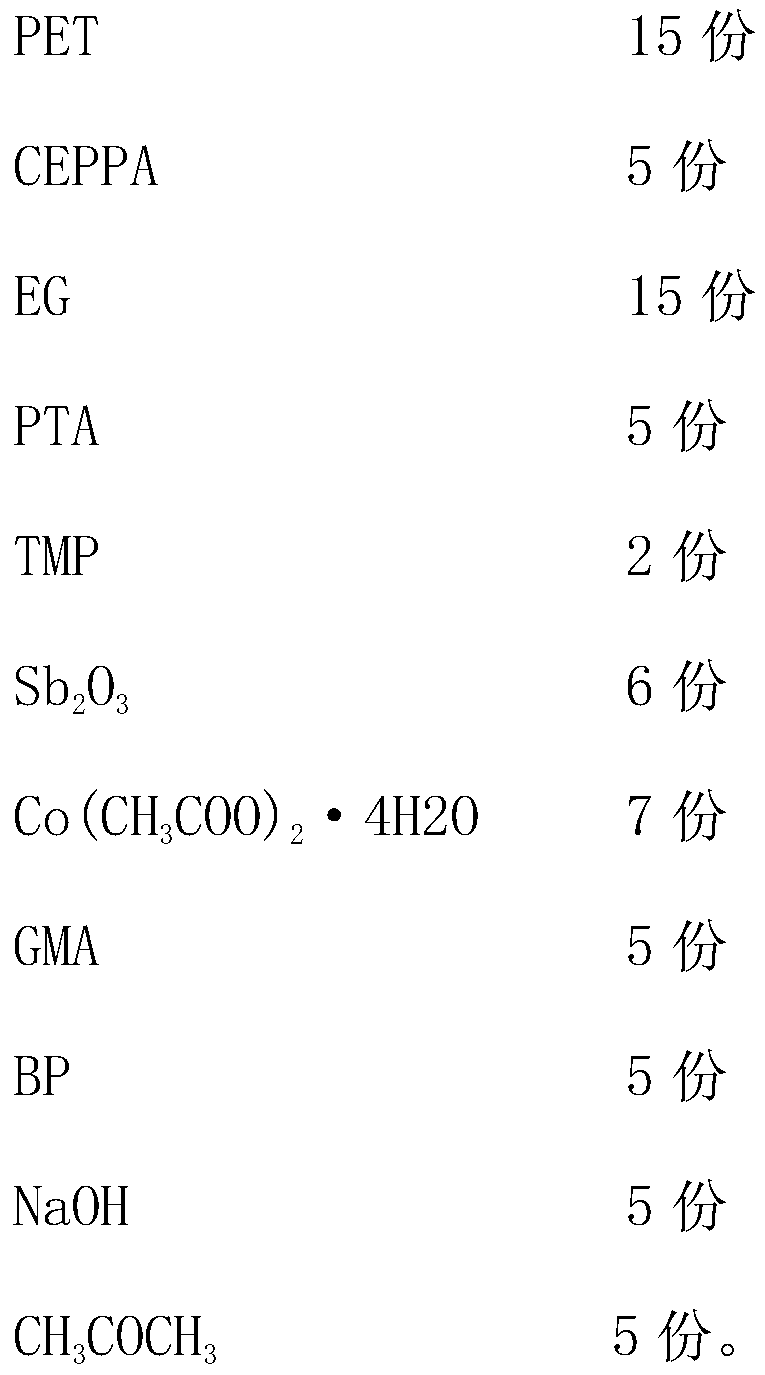

[0033] Step 2, preparation of flame retardant:

[0034]

[0035]

[0036] Measure a certain amount of EG, and slightly excess. Add the materials into the reactor that has been washed, and react for 3 hours while maintaining the internal temperature at 150°C. According to the amount of esterified water and the temperature at the top of the fractionating column, it is judged whether the pre-esterification is completed; after the pre-esterification is completed, a certain a...

Embodiment 3

[0044] Step 1. Fabric pretreatment: In order to have good adhesion between the flame retardant additive and the polyester fabric, the polyester fabric must be clean and free of dirt, so the polyester fabric should be pretreated before flame retardant treatment. The pretreatment solution contains sodium hydroxide, penetrant and surfactant. Put the polyester fabric into an appropriate pretreatment solution, boil it at 90°C for 30 minutes, take it out, wash it with clean water, and dry it for later use.

[0045] Step 2, preparation of flame retardant:

[0046]

[0047] Measure a certain amount of EG, and slightly excess. Add the materials into the reactor that has been washed, and react for 3 hours while maintaining the internal temperature at 150°C. Judge whether the pre-esterification is completed according to the amount of esterified water and the temperature at the top of the fractionating column; a certain amount of PTA, stabilizer TMP, toner Co(CH 3 COO) 2 4H2O, poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com