A construction method for the upper structure of a c-shaped stockyard

A construction method and material yard technology, applied in the field preparation of building components, industrial buildings, building components, etc., can solve the problems of many safety hazards, long construction period, and many high-altitude operations, so as to ensure construction quality and improve construction quality. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated below by specific examples.

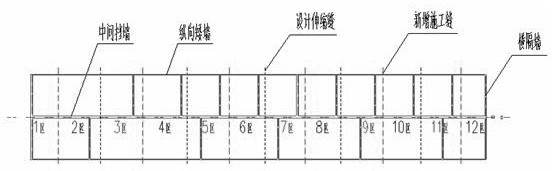

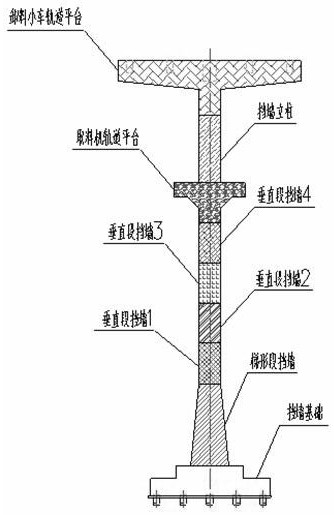

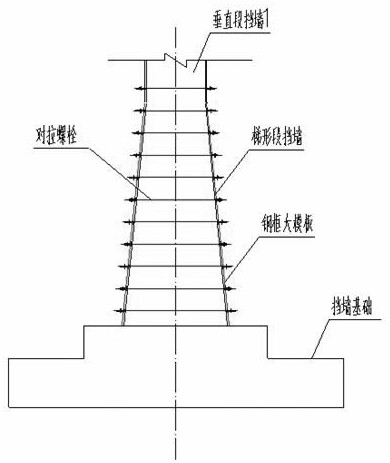

[0027] A construction method for the upper structure of a C-shaped stockyard retaining wall, such as Figure 1~3 shown, including the following steps:

[0028] (1) Construction preparation;

[0029] (2) Construction division

[0030] On the basis of the design expansion joints of the intermediate retaining wall, several construction joints are set to divide the upper structure of the stockyard into 12 construction areas, each construction area is between 30-50m in length, and each construction area includes the intermediate retaining wall, The horizontal partition wall and the vertical low wall shall be constructed according to the determined construction area. The construction of areas 1, 3, 5, 7, 9, and 11 shall be carried out first, and then the construction of areas 2, 4, 6, 8, 10, and 12 shall be carried out. area;

[0031] (3) Intermediate retaining wall construction

[0032] First con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com