A compact fine air filter suitable for high temperature and high pressure environment

A high-temperature, high-pressure, fine filter technology, applied in the direction of fuel air filter, combustion air/combustion-air treatment, machine/engine, etc., can solve the problems of large volume, affecting the power density of the power unit, etc., to achieve enhanced filtering effect, The overall layout is convenient and flexible, and the effect of ample space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

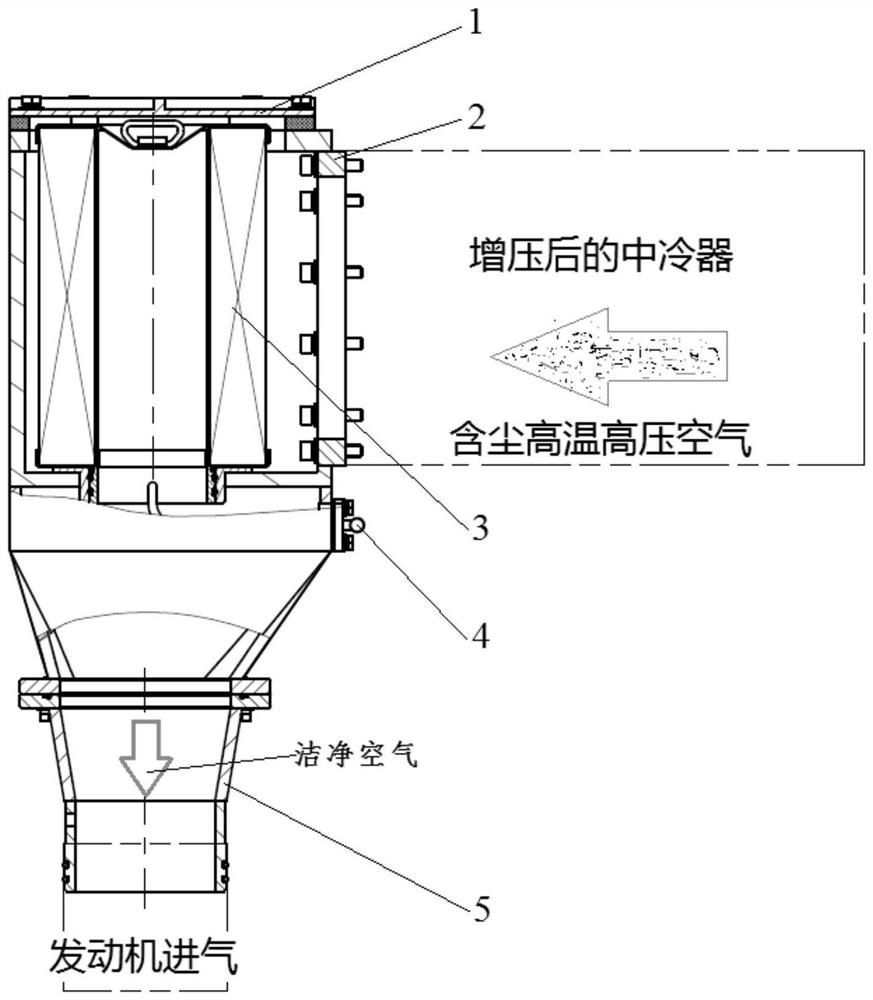

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0021] This embodiment provides a compact fine air filter suitable for high-temperature and high-pressure environments, which is arranged at the rear end of the engine supercharger, can work in high-pressure and high-temperature environments, and is small in size and compact in structure, which is conducive to improving the power density of the system .

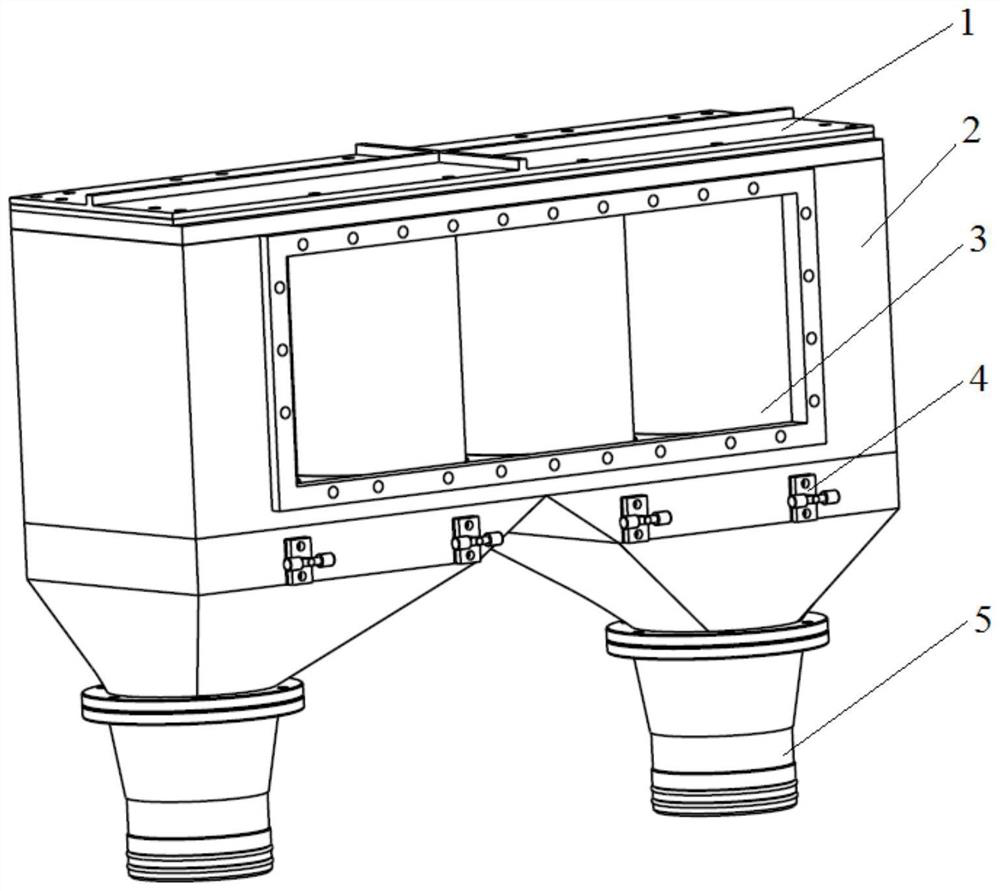

[0022] The fine air filter includes: an upper cover plate 1 , a housing 2 , a high-pressure filter element 3 , a pitot tube flowmeter 4 and an air outlet pipe 5 .

[0023] The connection relationship of the fine air filter is as follows: the fine air filter is arranged at the rear end of the engine supercharger, applicable to a high pressure range: 3 to 8 bar, and applicable to a high temperature range: 50 to 300°C; wherein, the housing 2 can withstand high temperature and high pressure without It is def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com