Small pressurized water reactor and containment long-term passive heat removal system

A pressurized water reactor and containment technology, which is applied in the field of reactor safety, can solve the problem of canceling the final heat sink water source, etc., and achieve the effects of improving plant site adaptability, long-term effectiveness of waste heat, and simplification of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technology of the present invention is further described below:

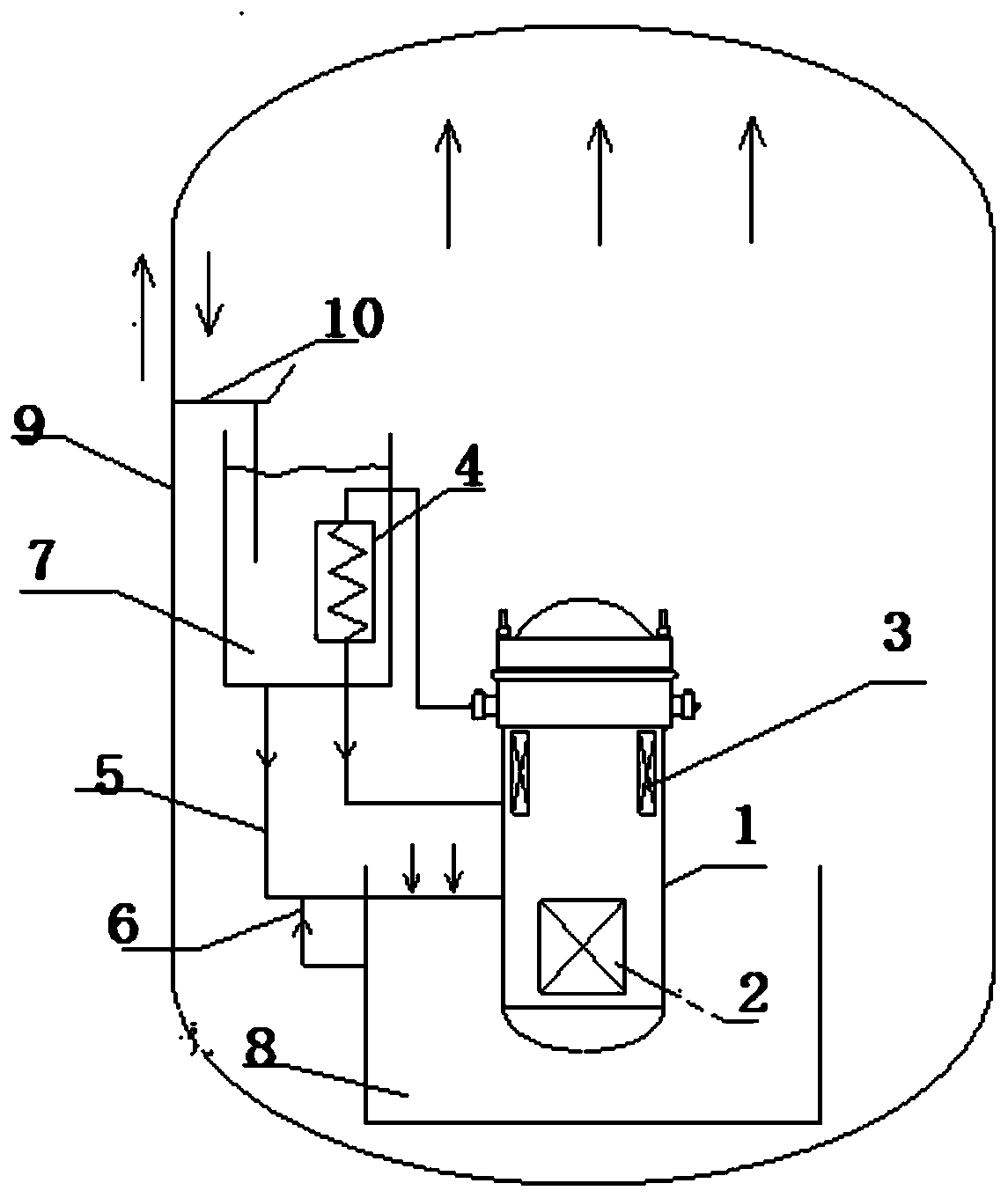

[0019] like figure 1 As shown, the present invention provides a long-term passive heat removal system for a small pressurized water reactor and containment, the system includes a passive residual heat exchanger 4, a low-pressure safety injection pipeline 5, a recirculation pipeline 6, and a low-pressure safety injection water tank 7. Containment pit 8, containment 9 and condensed water collection device 10 use air cooling on the outer wall of containment 9, and steam condenses on the inner wall to flow back, so that after the accident, no cooling water source is needed as the final heat sink, and only air is always used as the final heat sink. A heat sink is a passive heat removal method.

[0020] After the reactor 1 is shut down, the residual heat is stored in the core 2, the core 2 is contained by the pressure vessel of the reactor 1, the passive exhaust heat exchanger 4 is immersed in the low-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com