Automatic feeding type wire insulation cover removal method

A wire insulation and automatic feeding technology, which is applied in the direction of recycling technology, cable installation, dismantling/armored cable equipment, etc., can solve the problem of laborious cutting of wire insulation sleeves, and achieve the effect of small radial deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

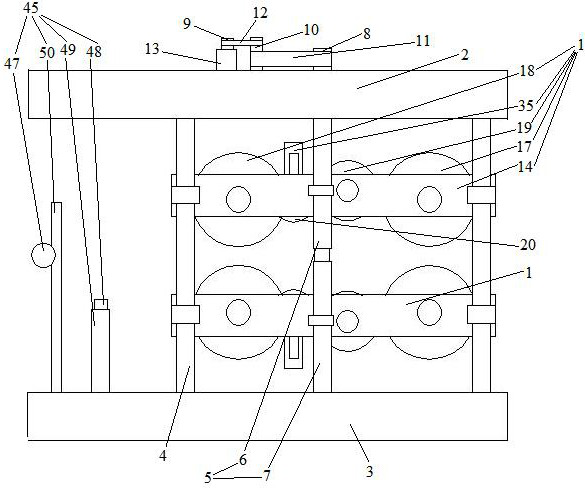

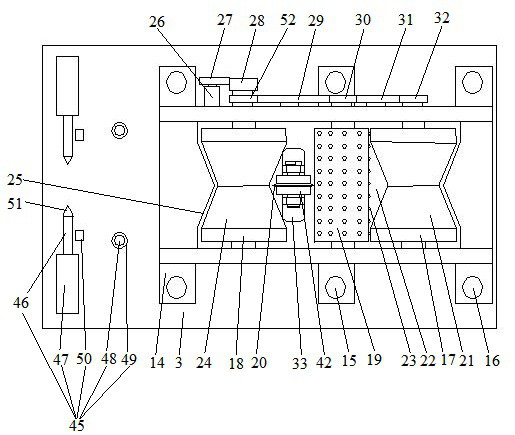

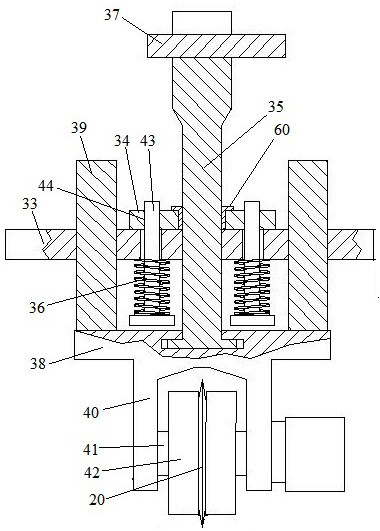

[0024]The present invention will be further described below in conjunction with the drawings and embodiments.

[0025]Seefigure 1 ,figure 2 ,image 3 withFigure 4, An automatic feeding method for removing wire insulation sleeve, realized by wire stripping machine. The guided peeling machine includes a frame, a driving mechanism and two cutting and conveying modules 1 distributed in the up and down direction. The frame includes a top plate 2 and a bottom plate 3. The top plate and the bottom plate are connected together by four vertical guide posts 4. The four vertical guide columns are distributed in a quadrilateral shape. Two screw rods 5 distributed along the front and rear directions are also arranged between the top plate and the bottom plate. The screw includes an upper half 6 and a lower half 7. The thread direction of the upper half is opposite to the thread direction of the lower half. The lower end of the lower half is rotatably connected to the bottom plate. The upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com