A safety plug socket

A technology of safety plugs and sockets, which is applied in the direction of the base/housing, coupling device, contact parts, etc., and can solve the problem that the space cannot be used in places with limited height, the tongue and the socket groove are not tightly inserted, and the verticality of the insertion angle cannot be guaranteed, etc. problem, achieve the effect of reducing the risk of sparking, realizing high current transmission, and lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

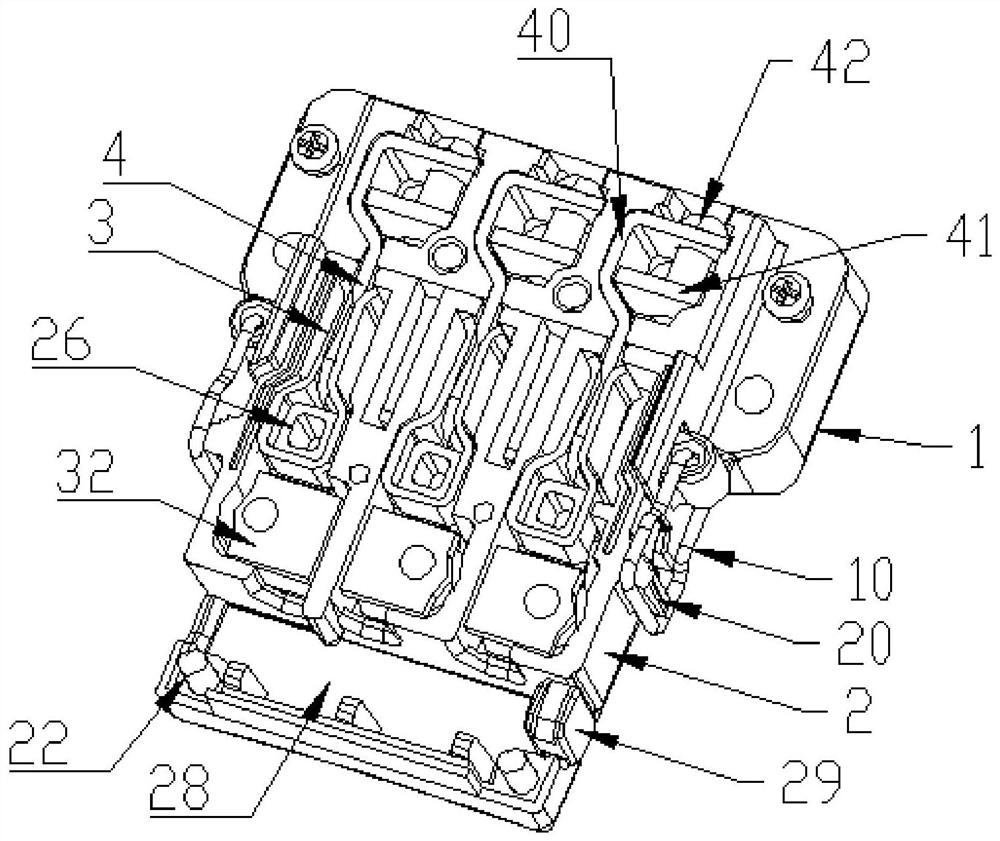

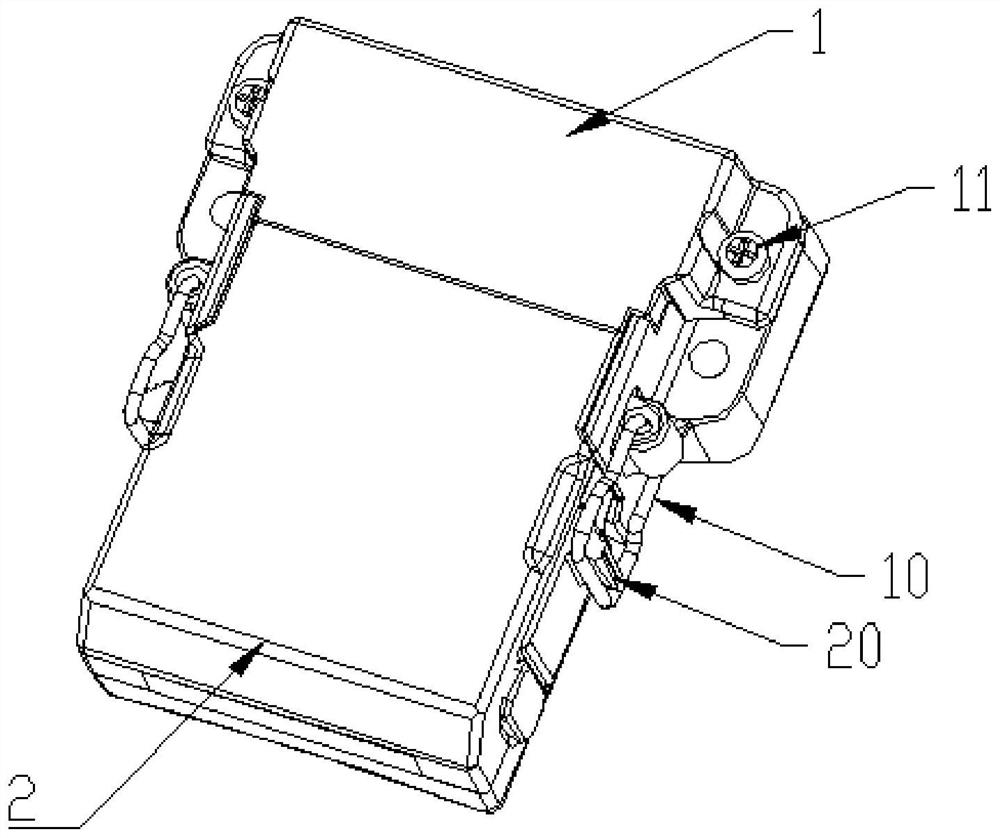

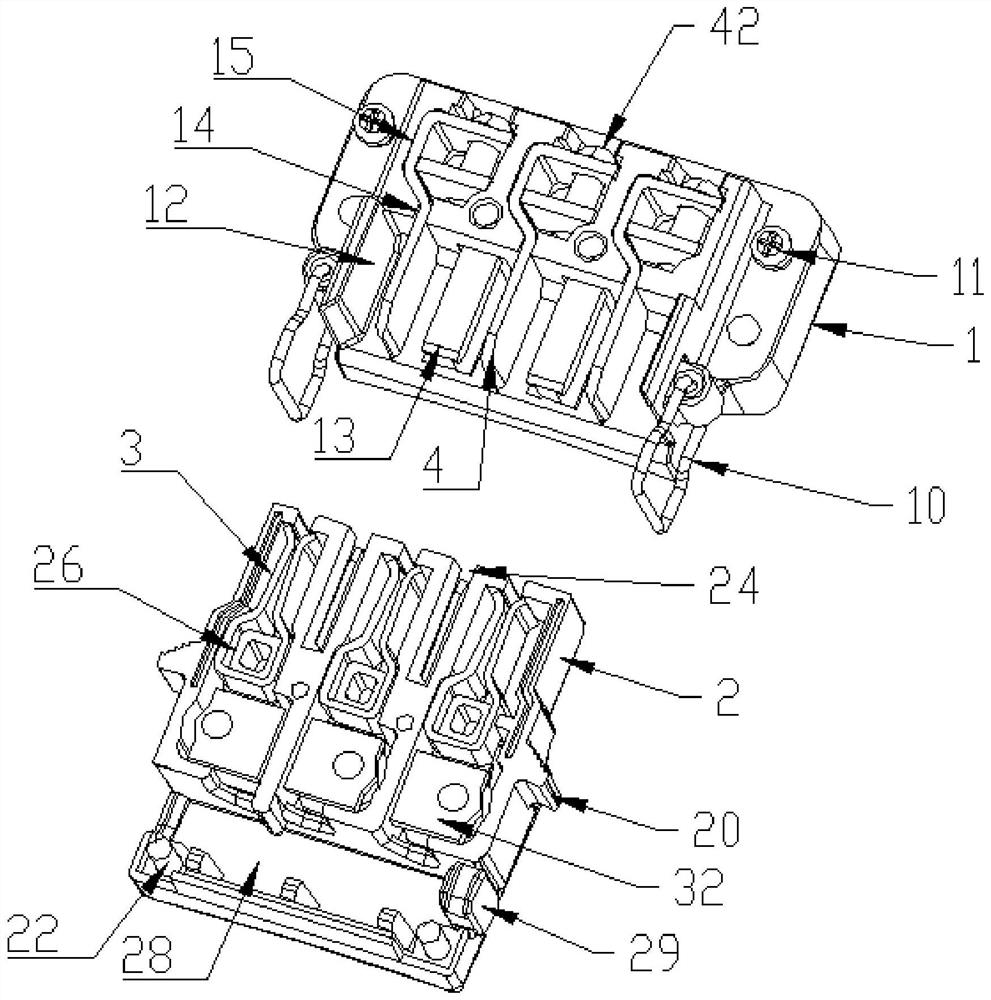

[0031] see Figure 1~6 , in an embodiment of the present invention, a safety plug and socket includes a plug box 1 and a socket box 2, the plug box 1 is fixed and installed by mounting bolts 11, and a plurality of plug pressure pins for external wiring are arranged in the plug box 1. Wire mechanism, the bottom of the plug box 1 is provided with an open downward plug groove 12, a plurality of conductive tongues 4 that are independently conductive to the plug wire pressing mechanism are arranged side by side in the plug groove 12, and multiple conductive tongues 4 are arranged in the socket box 2. A socket crimping mechanism for external wiring, the top of the socket box 2 is provided with an upward socket groove 23, and a plurality of conductive clips 3 independently conducting with the socket crimping mechanism are provided in the socket groove 23, and the socket groove 23 and the plug slot 12 are equipped with a fool-proof guiding plug-in mechanism, the conductive clip 3 is c...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is:

[0039] The plug connection slot 15 and the plug slot 12 communicate with each other through the provided tongue slot 14, the opening of the tongue slot 14 extends to the inner bottom surface of the plug slot 12 to form an L-shaped opening, and the conductive tongue 4 The rear side wall is clamped in the tongue slot 14 on the inner bottom surface of the plug slot 12, and the rear end of the conductive tongue 4 passes through the tongue slot 14 into the plug wiring slot 15 and bends along the left side inner wall of the plug wiring slot 15. After being folded, it is fixedly connected with the tongue crimping bolt 42 on the top of the plug wiring groove 15, and the tongue clamping groove 14 provided can clamp the conductive tongue 4 well between the plug groove 12 and the plug wiring groove 15 to ensure electric conduction. When the tongue piece 4 is inserted into the conductive clip 3 of the plug box 1 , the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com