A kind of manufacturing method of braided belt for police use

A manufacturing method and technology of belts, which are applied in the direction of braided fabrics, clothing belts, textiles, and papermaking, can solve the problems of shortening the service life of police belts, unbalanced force on belts, and low efficiency, so as to improve assembly efficiency and quality, The effect of reducing labor intensity and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

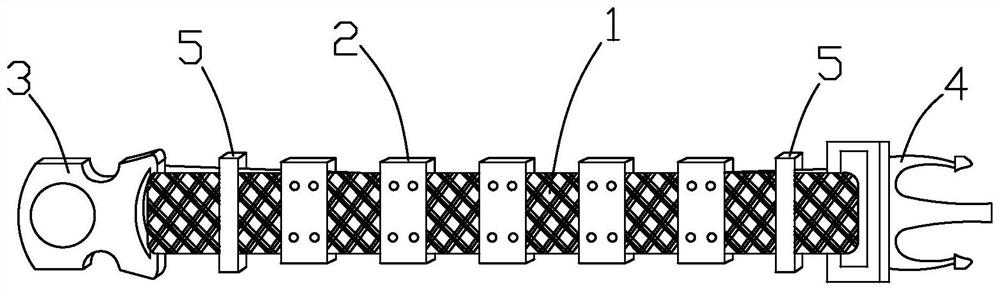

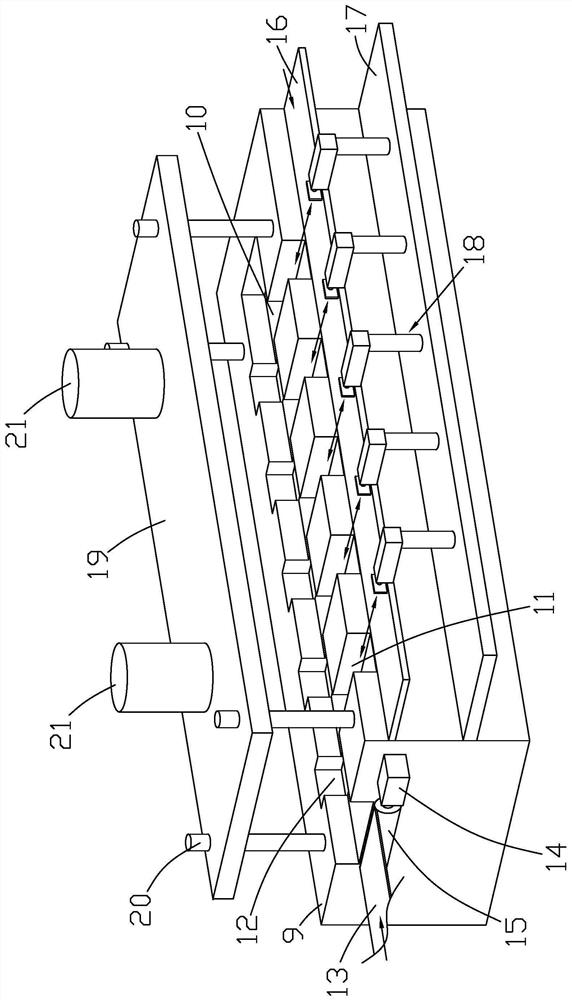

[0059] Such as Figure 1 to Figure 5 Shown, be the manufacture method of a kind of police braided belt of the present invention, comprise the steps:

[0060] 1) Belt body 1 braid

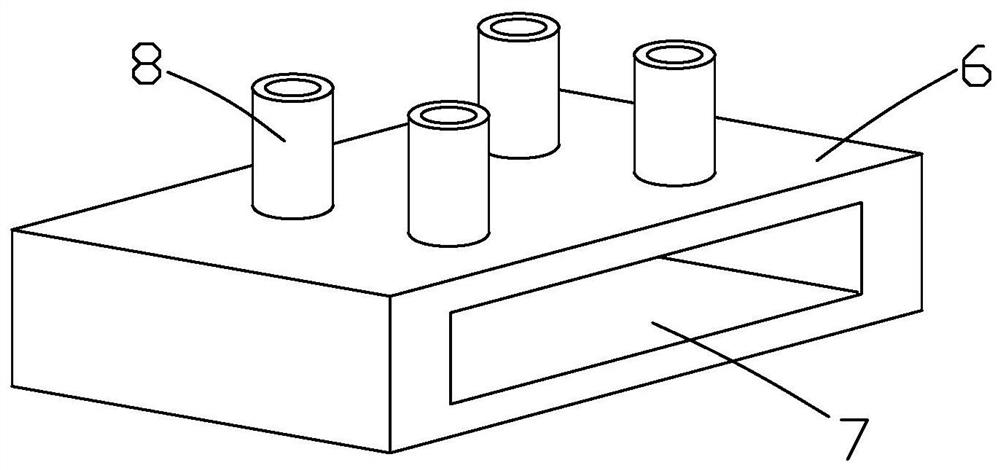

[0061] a. First, select high-strength elastic fibers according to the requirements of the woven belt, and weave the first belt body with the required width and length through the knitting machine. Through the design of the first belt body, the toughness of the entire belt body 1 can be improved and the woven belt can be extended. service life of the first belt body; when the first belt body is weaving, the front end of the first belt body is sewed with yarn to prevent it from falling apart; The stability of the connection at both ends of the body prevents the first waist belt body from being disassembled when it passes through the frame body 6 and cannot be assembled with the suspension assembly 2 .

[0062] b. Then make the second belt body according to the size of the first belt body; when the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com