Smashing pipe device for building wood board production and machining equipment

A technology for crushing pipes and wood, which is applied in solid separation, screens, grids, etc., and can solve the problems of poor fluidity of wood blocks and low crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The purpose of the present invention is to provide a crushing tube device for building wood board production, to solve the problem that the existing crushing equipment is divided into coarse crushing and fine crushing in order to improve the efficiency of crushing, but in fine processing, due to the The fluidity is poor, mostly because it falls on the pulverizer by its own gravity, and the pulverization efficiency is not high. In order to achieve the above purpose, the following technical solutions are specifically provided:

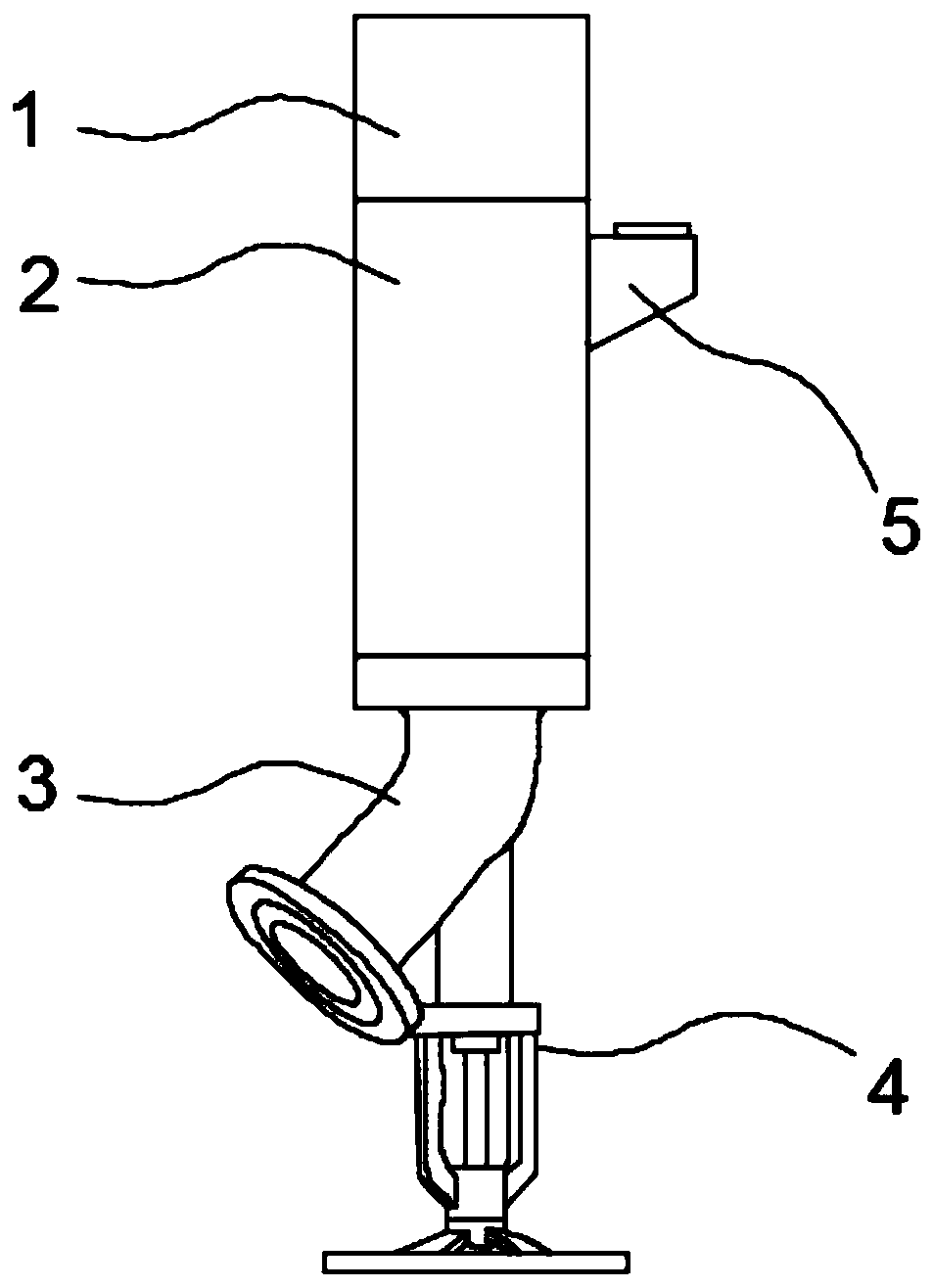

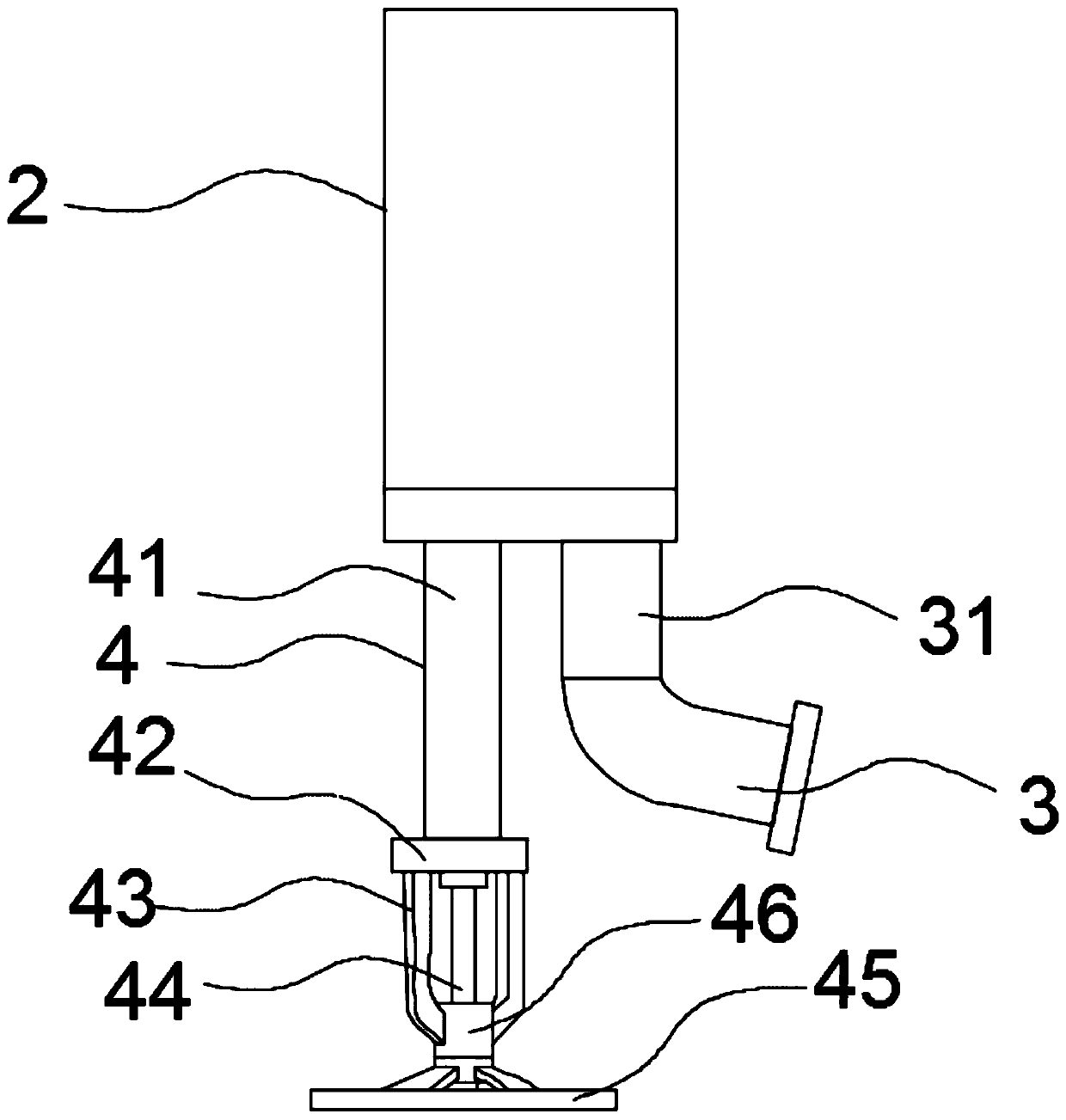

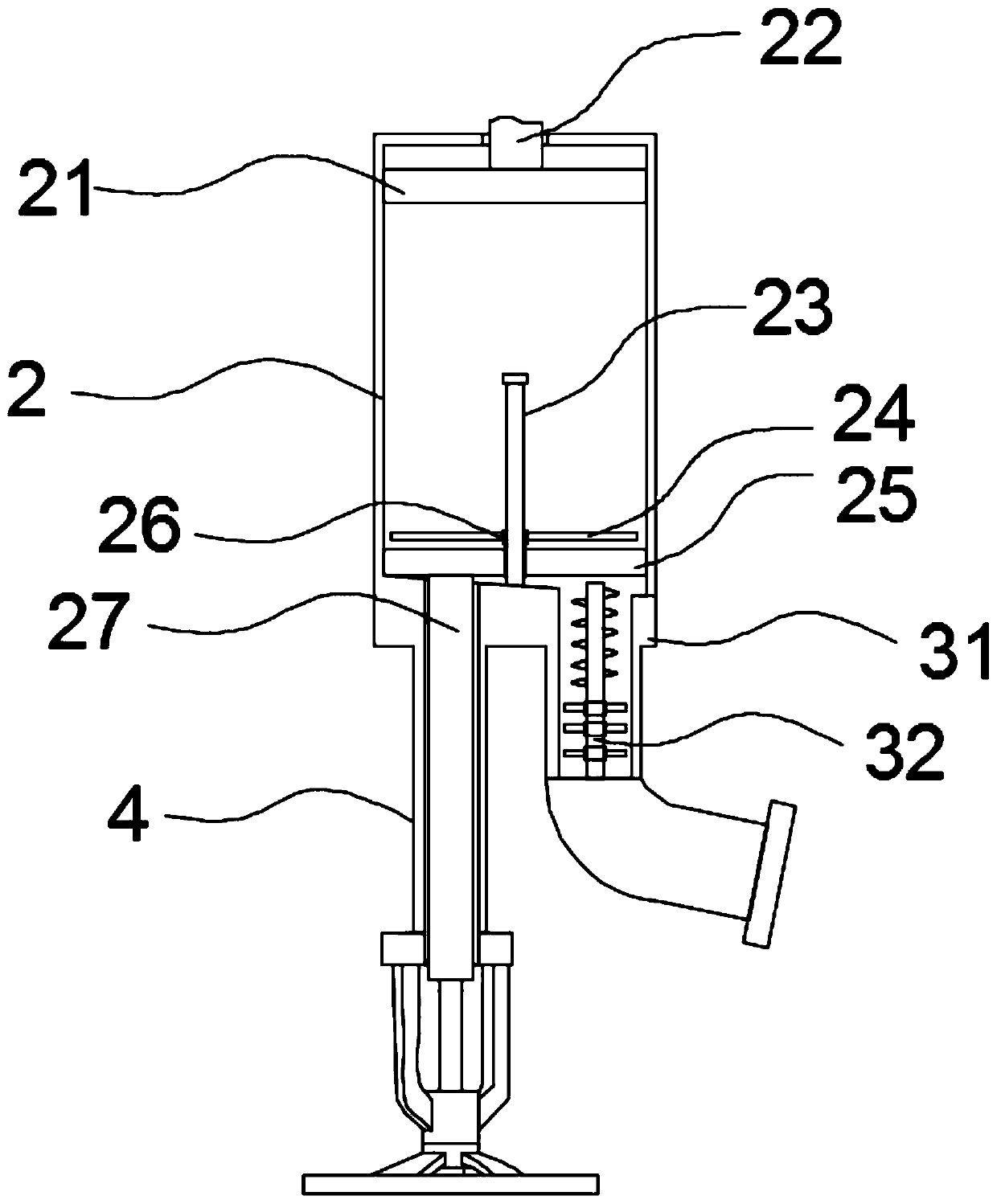

[0034] In the embodiment of the present invention, such as Figure 1-4 As shown, a crushing pipe device for the production of building timber boards includes a pipe body 2, and the inside of the pipe body 2 is connected with a freely movable lower pressing plate 21 and a screen 25; the device also includes a telescopic structure A1. The telescopic structure A1 is installed on the lower pressing plate 21, and can control the movement of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com