Raw material recycling and crushing device for bobbin paper production

A technology of crushing device and bobbin paper, which is applied to fiber raw materials, fiber raw material processing, papermaking, etc., and can solve problems such as blockage and low efficiency of material crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

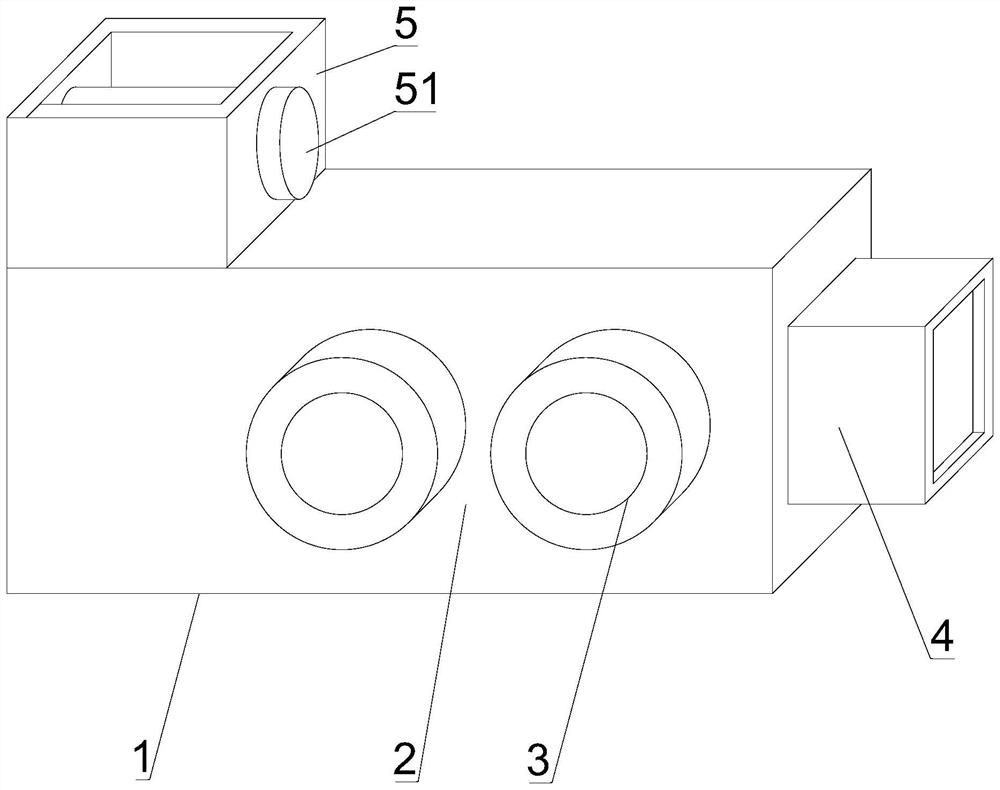

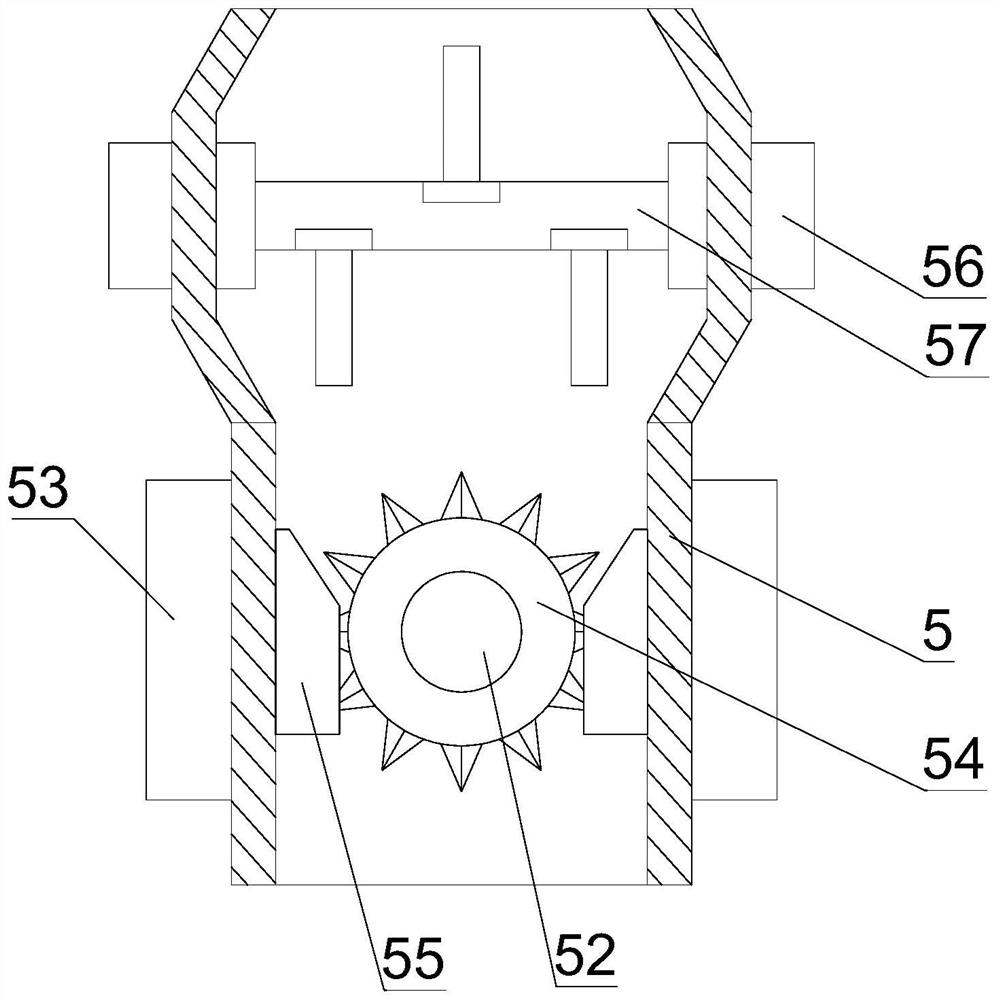

[0049] like Figure 1-10 As shown in the figure, the present invention provides a raw material recovery and crushing device for bobbin paper production, including a bobbin paper raw material recovery and crushing device body 1, and the bobbin paper raw material recovery and crushing device body 1 includes a material guide filter device 2, and the material guide filter The crusher 5 is detachably installed on the outer surface of the top left side of the crusher 2, and the lap crusher 55 is detachably installed on the inner surfaces of the left and right sides of the crusher 5. The top sides of the crusher 5 A rotating machine 56 is detachably mounted on the outer surface, and a cutting guide roller 57 is detachably connected to the output end of the rotating machine 56 .

[0050] The crushing device 5 is used for crushing the paper, the material guiding filter device 2 is used for inhaling and collecting the flying debris, the cutting and guiding rod 57 is rotated by the rotat...

Embodiment 2

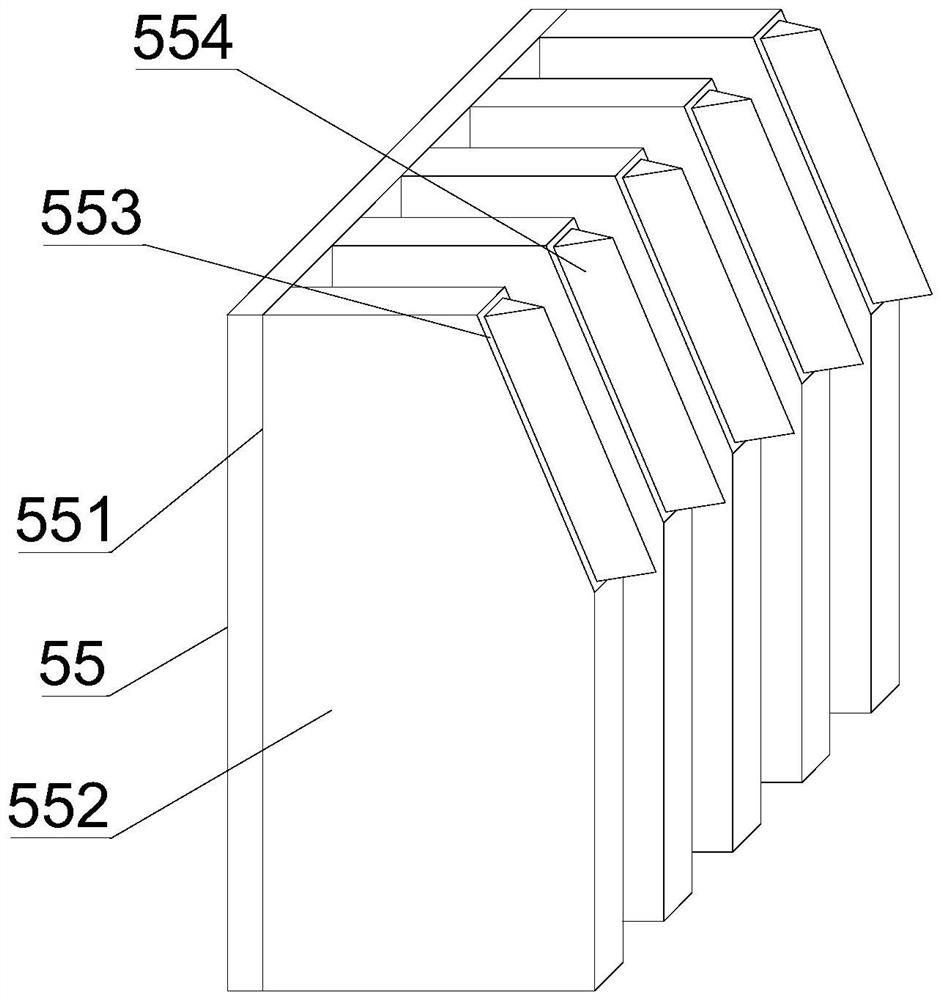

[0052] like Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the lap crushing device 55 includes a clamping plate 551, and the outer surface of the right side of the clamping plate 551 is detachably connected with a strip-shaped The crushing plate 552, the top of the strip-shaped crushing plate 552 is provided with a clamping groove 1 553, and a tearer 554 is movably clamped inside the clamping groove 1 553.

[0053] In this embodiment, the top of the bar-shaped crushing plate 552 is used to block the material, and the tearer 554 is used to overlap the material. Pulling down, using the pulling force generated when the blade rotates and the tearer 554 to break the surface of the material, the effect of blocking the gap between the cutter and the wall and effectively cutting the material is achieved.

Embodiment 3

[0055] like Figure 1-10 As shown, on the basis of Embodiment 2, the present invention provides a technical solution: preferably, the tearer 554 includes a triangular crushing head a1, and the outer surfaces of the top two sides of the clip plate 551 are detachably connected with arc-shaped The tearing knife a2, the bottom outer surface of the triangular breaking head a1 is detachably connected with a buffer elastic wire a3, and one end of the buffer elastic wire a3 is detachably connected with a clamping block a4, and the bottom outer surface of the clamping block a4 is connected There are two clamping grooves a5, and L-shaped clamping rods a6 are detachably connected to the edges on both sides of the bottom of the triangular crushing head a1. The outer surfaces of the clamping blocks a4 are provided with empty grooves a7. A sliding rod a8 is detachably connected to the upper and lower inner surfaces of the a7, and one end of the L-shaped clamping rod a6 is slidably sleeved o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com