A method for harmless treatment of urban waste polyurethane foam materials

A technology of harmless treatment and foaming materials, applied in the direction of mechanical material recycling, plastic recycling, recycling technology, etc., can solve the problems of flexible foam that cannot be processed, consumes a lot of fuel, occupies a large amount of land, etc., and achieves economic benefits. It has obvious social benefits, low operating costs, and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

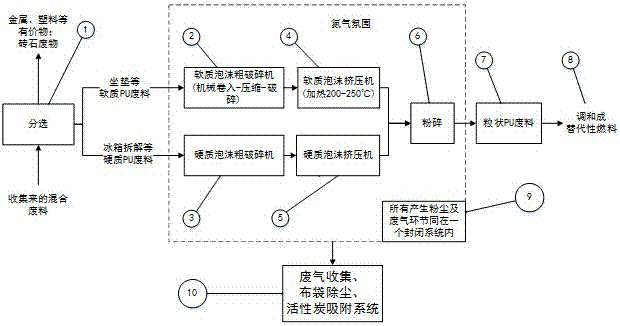

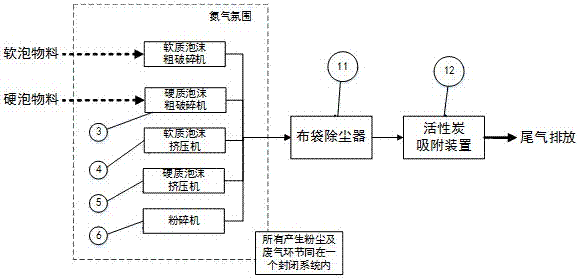

[0051] Below in conjunction with process flow chart, the embodiment of the present invention is described in detail:

[0052] Refer to the process flow figure 1 , the process steps of the present invention are sorting ①, soft foam coarse crushing ② and rigid foam coarse crushing ③, soft foam extruding ④ and rigid foam extruding ⑤, pulverizing ⑥, compressed foam granule finished product ⑦, blending In the process of forming alternative fuel ⑧, foaming agent collection ⑩, etc., all links use belt conveyors for material transfer, as follows:

[0053] 1. Sorting: Firstly, the metal mixed in the waste polyurethane foam materials collected from all over the city (hard and easily damaged knives, valuable), hot-melt plastics over 10cm in size (higher value than heat energy utilization) ), stones (hard and easily damaged knives, worthless) are sorted out, and the waste polyurethane foam materials are stacked separately according to soft foam and hard foam.

[0054] 2. Coarse crushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com