Device for cleaning carbon deposits on intake manifold

An intake manifold and carbon deposition technology, which is applied in the field of engine cleaning equipment, can solve the problems of time-consuming cleaning work, poor engine air intake, engine powerlessness, etc., and achieve the effect of convenient cleaning work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

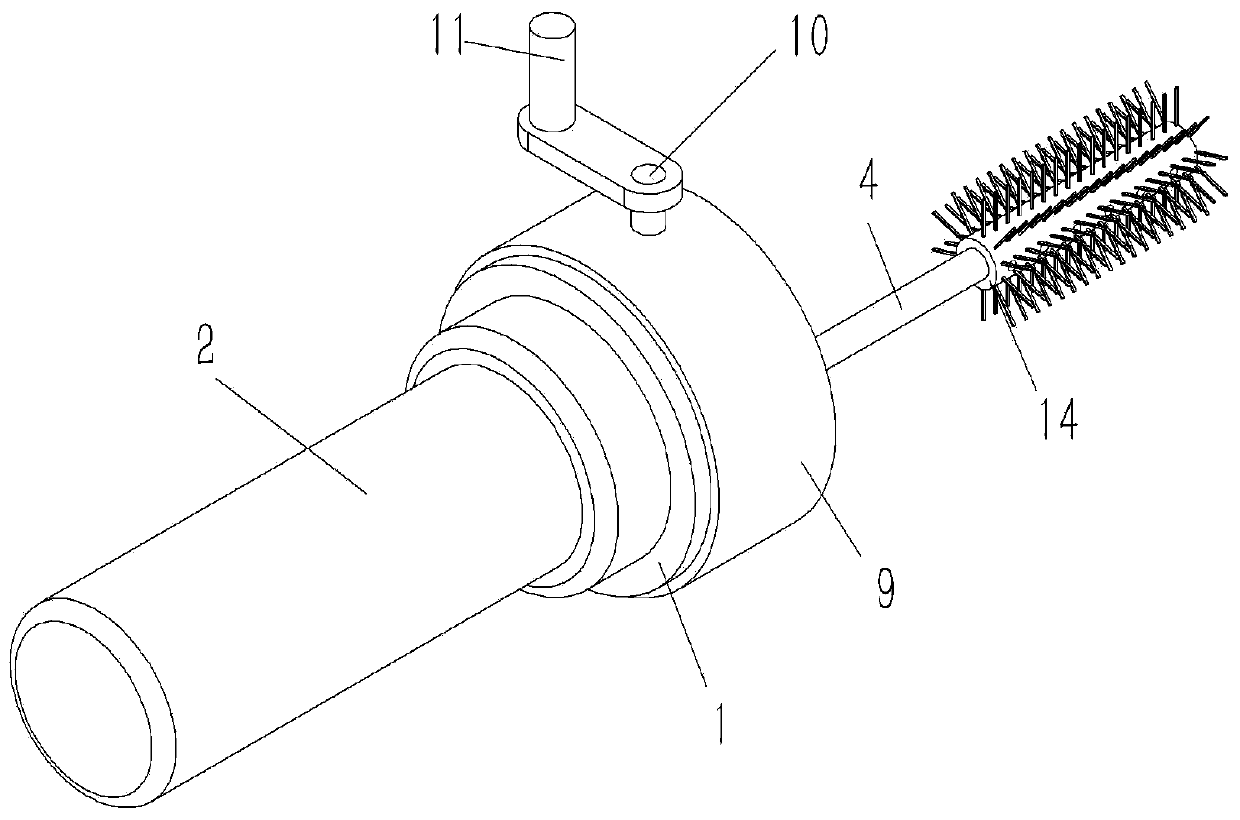

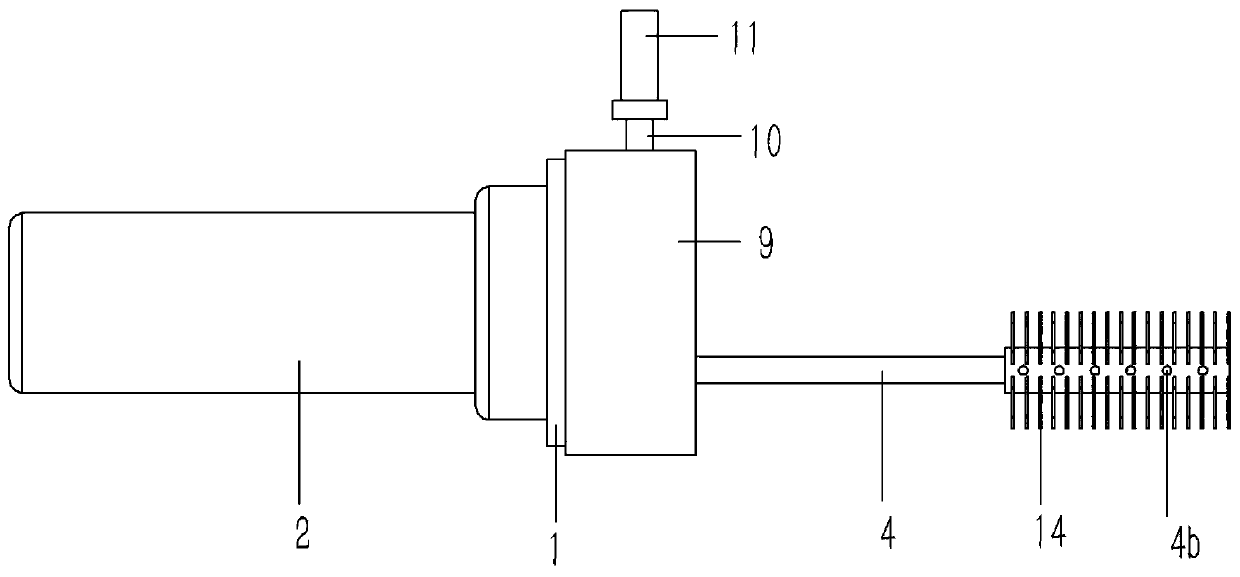

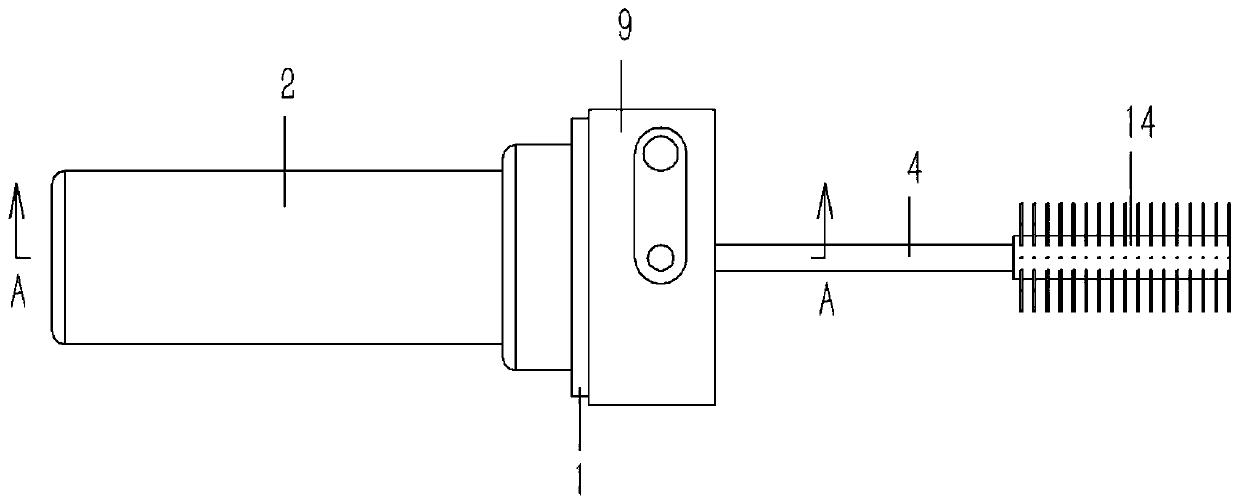

[0019] Example: see Figure 1 to 4 As shown, a device for cleaning carbon deposits in an intake manifold includes a cylindrical base 1, a circular recess 1a is formed on the right end of the base 1, and a handle 2 is fixed on the left end of the base 1. 2 A cleaning agent storage cavity 2a is formed in the cleaning agent storage cavity 2a of the handle 2, a screw 3 is inserted into the cleaning agent storage cavity 2a of the handle 2, and the right end of the screw 3 is inserted into the recess 1a of the base 1 through the base 1 and inserted into the sleeve The driven gear 6 is fixed, the outer ring of the recess 1a is inserted with an eccentric shaft 4, the eccentric shaft 4 is inserted on the base 1 and formed with a central hole 4a, the central hole 4a of the eccentric shaft 4 and the cleaning agent of the handle 2 The storage cavity 2a is in communication; the eccentric shaft 4 is fixed with a driving gear 5 and a driven bevel gear 7 in a sleeve, the driving gear 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com