A method of tie-rod segmented modular type riser

A technology of segmented modules and tie rods is applied in the field of heat exchanger manufacturing, which can solve problems such as hidden safety hazards and inability to fasten connections with threads, and achieve the effects of improving production efficiency, ensuring heat exchange stability and service life, and connecting accurate connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

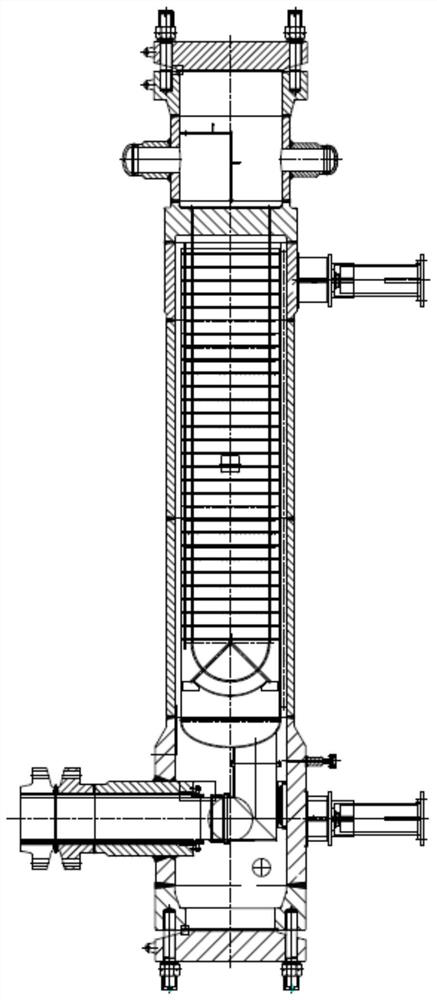

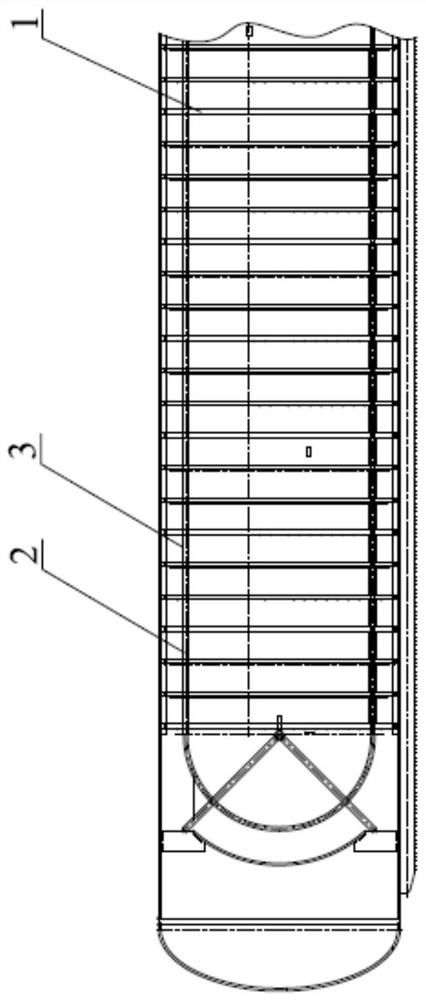

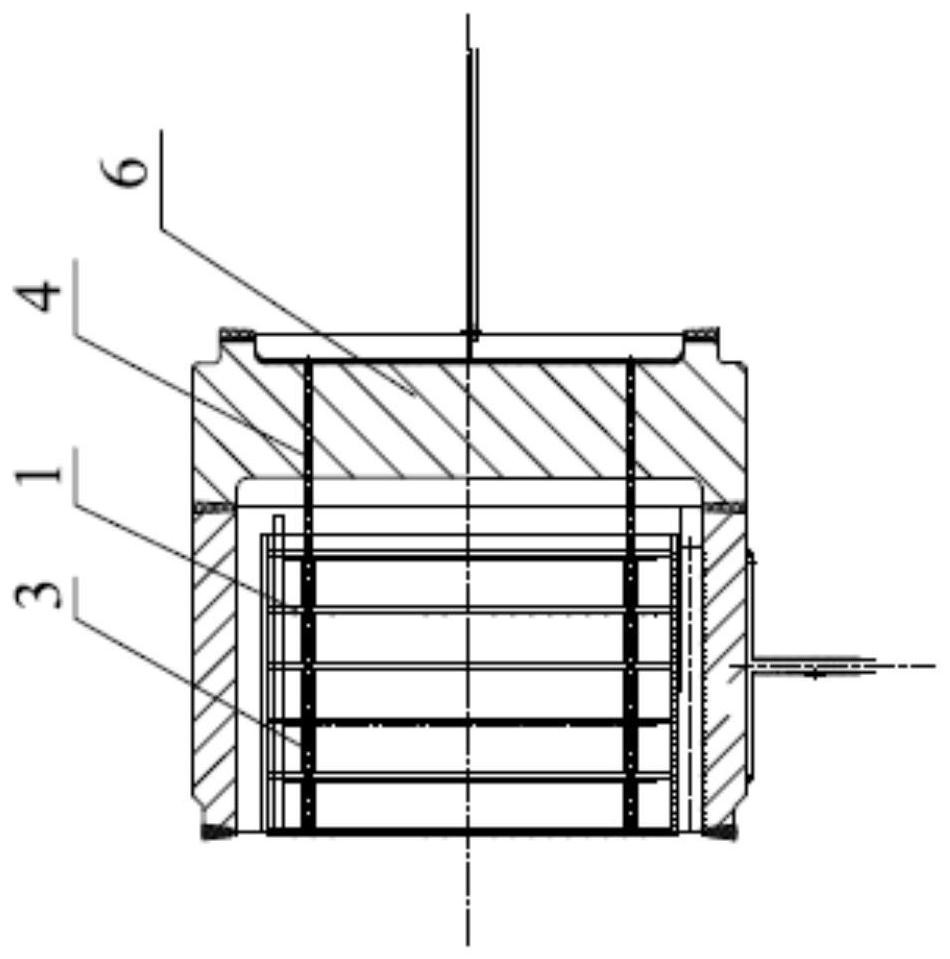

[0030] Specific implementation mode one: refer to Figure 1 to Figure 4 To illustrate this embodiment, this embodiment provides a method for assembling riser racks in segmented and modular tie rods, and the method is realized through the following steps:

[0031] Step 1: Cut off the long tie rod 2 and the short tie rod 4 according to the assembly position of each tie rod, mark the position line of the connecting section that needs to be processed for the marking mark, and pay attention to processing the two ends of the long tie rod 2 into the same length connecting section, and the two ends of the short tie rod 4 The ends are respectively processed into connecting sections of the same length, and the length of the connecting section on the long tie rod 2 is equal to the length of the connecting section on the short tie rod 4;

[0032] Step 2: To make the pup joint module, first, N No. 1 connection holes are evenly distributed on one end of the tube sheet 6, and N is a positive...

specific Embodiment approach 2

[0037] Specific implementation mode two: refer to Figure 1 to Figure 4Describe this embodiment, this embodiment is to further limit the step 1 described in the specific embodiment 1, in this embodiment, the length of the long tie rod 2 in the step 1 is 3-5 times the length of the short tie rod 4 . Other compositions and connection methods are the same as those in Embodiment 1.

[0038] Such setting takes into account the dimensional requirements of the sub-joint modules when they are assembled, as well as the impact on stiffness caused by the dimensional difference of the long and short-joint modules during subsequent connection. If the length difference between the long tie rod 2 and the short tie rod 4 is large, the rigidity of the connection will be weak, which will easily affect the service life of the heat exchanger.

specific Embodiment approach 3

[0039] Specific implementation mode three: refer to Figure 4 Describe this embodiment, this embodiment is to further limit the step 1 described in the specific embodiment 1. In this embodiment, the length of the connecting section at both ends of the long tie rod 2 and the short tie rod 4 in the step 1 is equal, and the length of the connecting section is It is 3-5cm. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com