Automatic grinding machine for deep-hole integrated cold heading bolt mold

A technology for cold heading bolts and grinding machines, which is applied to machine tools, grinding machines, and manufacturing tools designed for grinding the rotating surface of workpieces, can solve the problems of high labor intensity, high labor costs, and low grinding efficiency, and reduce labor intensity. , saving labor costs, and the effect of fast processing and grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

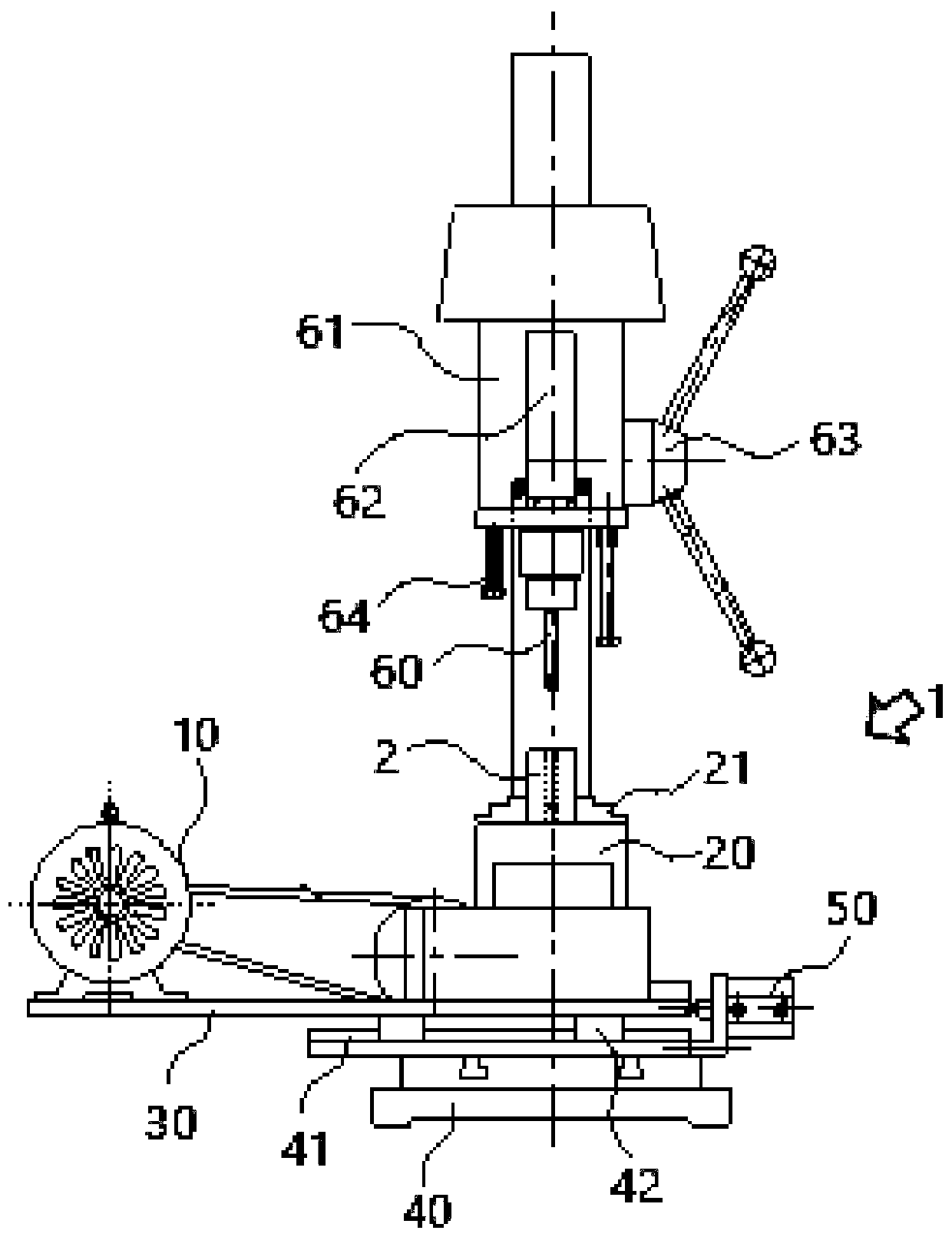

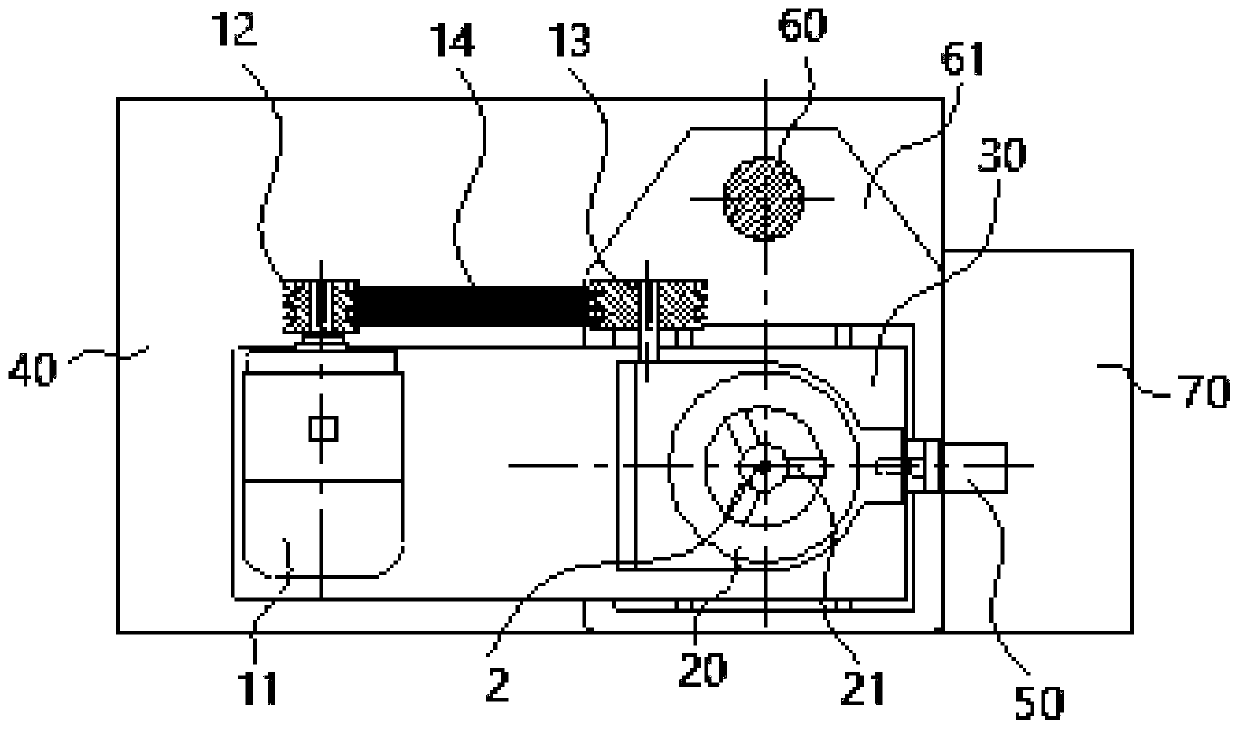

[0018] The embodiment of the present invention discloses an automatic grinding machine for a deep hole integrated cold heading bolt mold, which includes a rotary table mounted on a rotating worktable driven by a worktable driving part, and a workpiece positioning part is arranged on the rotary table, and the workpiece positioning part is used for Position and install the cold heading bolt mold to be processed and ground in one piece, and the rotary table can be installed on the slide table in a relatively rotatable manner, and the slide table is slidably installed on the processing installation table, and the slide table is equipped with X-axis or Y-axis drive It is used to adjust the displacement in the X-axis or Y-axis direction; above the workpiece positioning part, there is a grinding rod for deep hole processing and grinding with the cold heading bolt mold. The grinding rod is driven by the grinding motor installed on the grinding installation frame, and the grinding The m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap