Preparation method for colored natural latex tube with bi-color cross section

A technology of natural latex and cross-section, applied in the field of natural latex tubes, can solve the problems of difficulty in preparing thick-walled color natural latex tubes, reduced production efficiency by heat-sensitive extrusion method, low extrusion efficiency and quality qualification rate, etc. The effect of preparation cost, increase of enterprise economic benefit, and improvement of quality pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

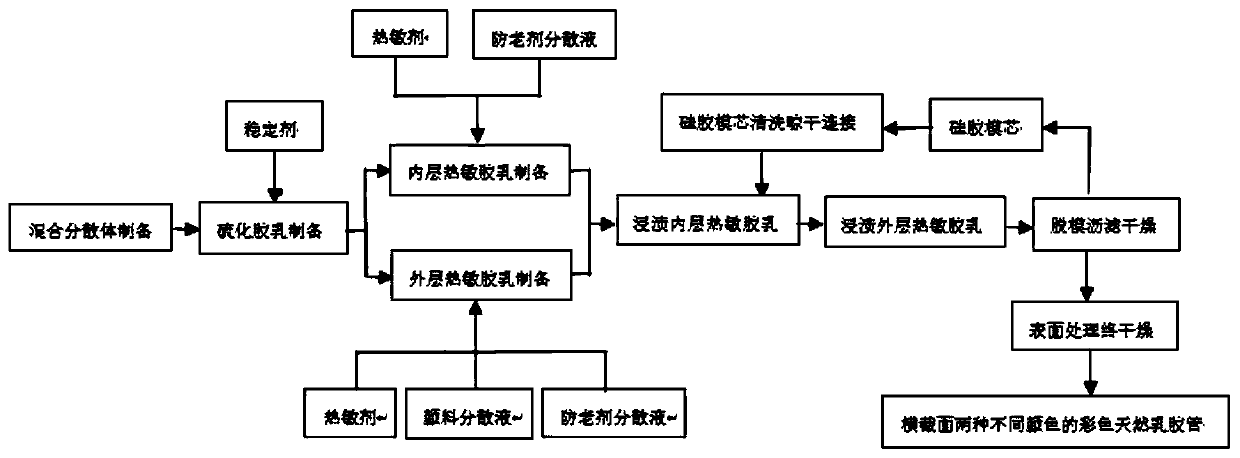

Method used

Image

Examples

Embodiment 1

[0063] A kind of circular dipping method prepares the method for the natural latex tube (6mm * 13mm) of cross-section two-color, outer surface red, comprises the following steps:

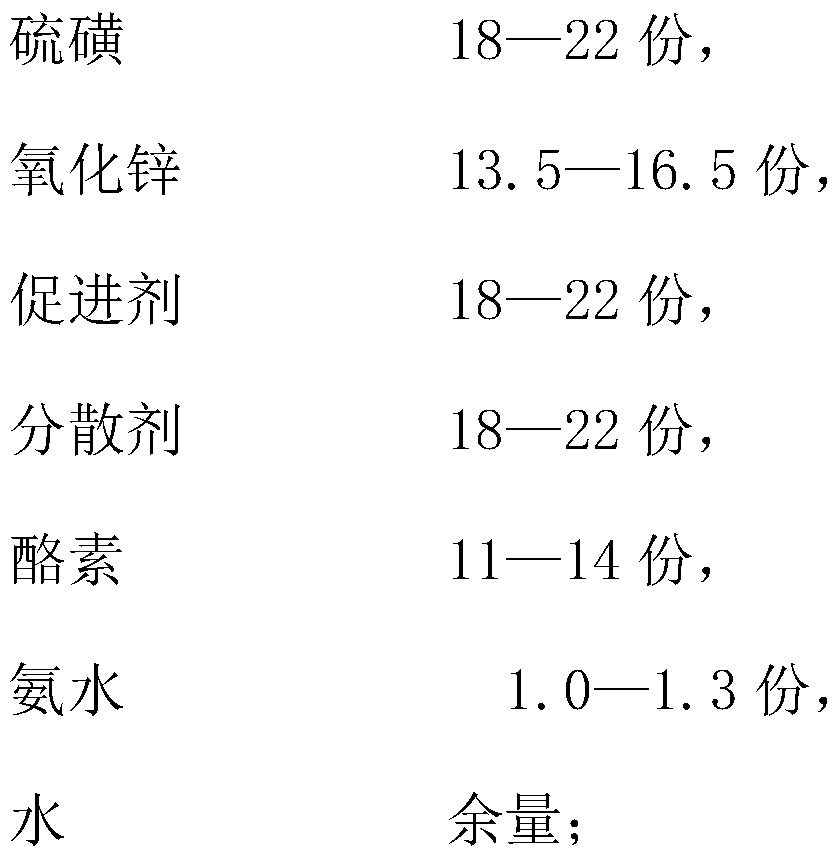

[0064] (1) preparation solid content is the mixing dispersion of 50wt%:

[0065]

[0066] Put the above materials into a ball mill with a rotating speed of 80 rpm to grind for 60 h, and filter through a stainless steel screen with a pore size of 0.28 mm to obtain a mixed dispersion with a solid content of 50 wt%.

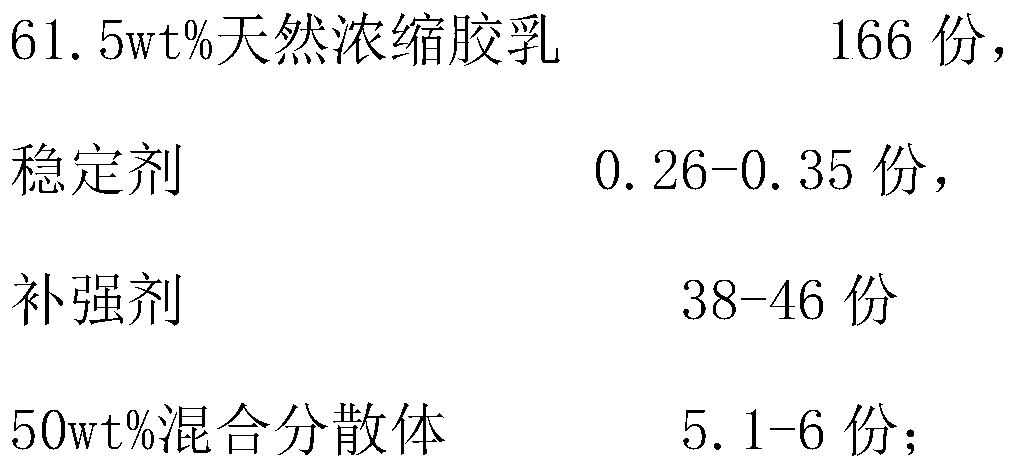

[0067] (2) preparation solid content is the vulcanization latex of 55wt%:

[0068]

[0069]

[0070] Put the concentrated latex in the latex vulcanization tank, add the stabilizer Pingping and O under stirring conditions, pass hot water into the interlayer of the latex vulcanization tank to raise the temperature of the latex to 40°C, add the mixed dispersion, 45wt% MG49 Tianjia Latex, 28wt% epoxidized natural latex, 50wt% water-based ultrafine calcium carbonate and deionized wat...

Embodiment 2

[0087] A kind of circular dipping method prepares the method for the natural latex tube (7mm * 15mm) of cross-section two-color, outer surface green, comprises the following steps:

[0088] (1) preparation solid content is the mixing dispersion of 50wt%:

[0089]

[0090] Put the above materials into a ball mill with a rotating speed of 80 rpm to grind for 60 h, and filter through a stainless steel screen with a pore size of 0.28 mm to obtain a mixed dispersion with a solid content of 50 wt%.

[0091] (2) preparation solid content is the vulcanization latex of 55wt%:

[0092]

[0093]

[0094] Put the concentrated latex in the latex vulcanization tank, add the stabilizer Pingping and O under stirring conditions, pass hot water into the interlayer of the latex vulcanization tank to raise the temperature of the latex to 40°C, add the mixed dispersion, 45wt% MG49 Tianjia Latex, 28wt% epoxidized natural latex, 50wt% water-based ultrafine calcium carbonate and deionized w...

Embodiment 3

[0111] A kind of circulation dipping method prepares the method for the natural latex tube (7mm * 16mm) of cross-section two-color, outer surface black, comprises the following steps:

[0112] (1) preparation solid content is the mixing dispersion of 50wt%:

[0113]

[0114] Put the above materials into a ball mill with a rotating speed of 80 rpm to grind for 60 h, and filter through a stainless steel screen with a pore size of 0.28 mm to obtain a mixed dispersion with a solid content of 50 wt%.

[0115] (2) preparation solid content is the vulcanized latex of 55wt%:

[0116]

[0117]

[0118] Put the concentrated latex in the latex vulcanization tank, add the stabilizer Pingping and O under stirring conditions, pass hot water into the interlayer of the latex vulcanization tank to raise the temperature of the latex to 38°C, add the mixed dispersion, 45wt% MG49 Tianjia Latex, 28wt% epoxidized natural latex, 50wt% water-based ultrafine calcium carbonate and deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com