Railway hopper car with large-volume movable end wall

A funnel car, large volume technology, applied in the direction of funnel car, railway car body, railway car body parts, etc., can solve the problems of small vehicle volume, low load, low space utilization rate, etc., to achieve strong transportation capacity, heavy load, The effect of large structural volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

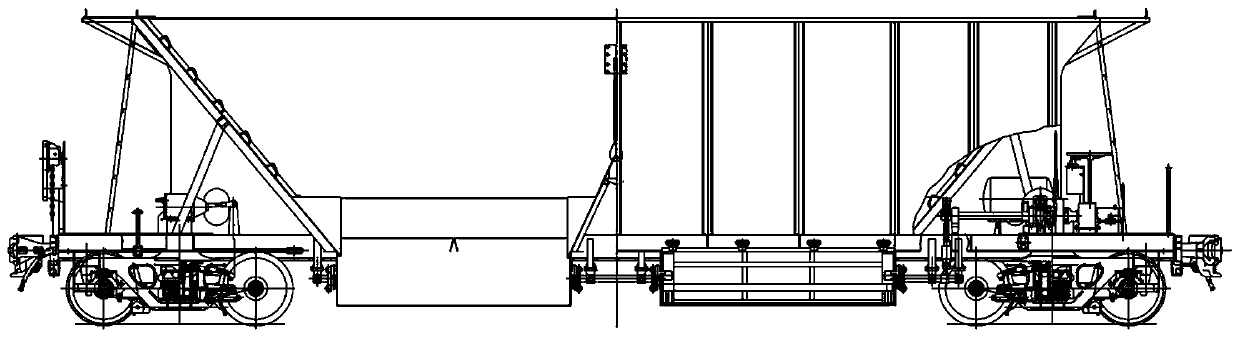

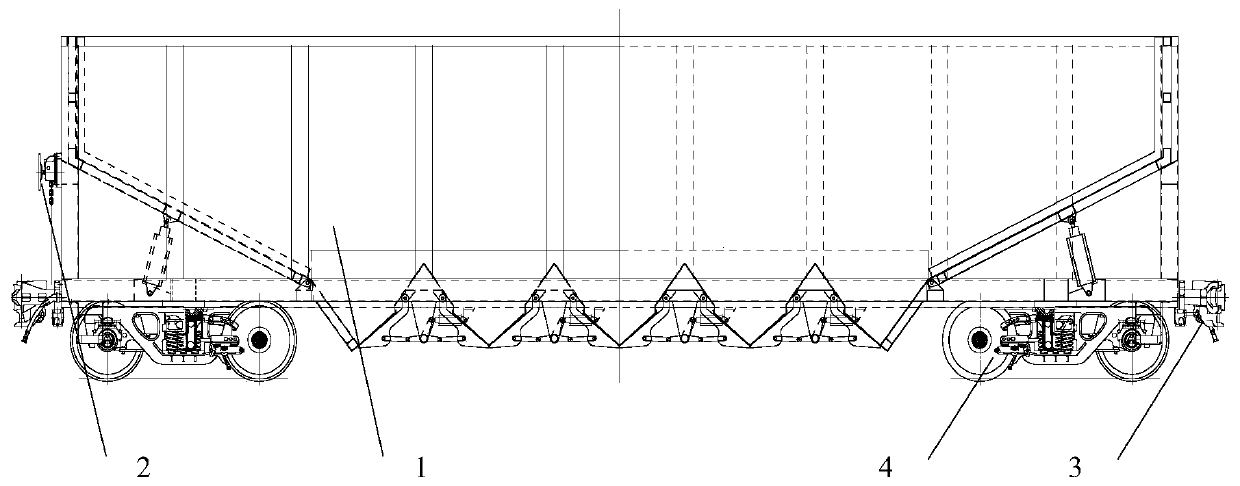

[0031] refer to Figure 1 to Figure 14 As shown, a railway hopper car with a large-volume movable end wall in this embodiment includes a car body 1, a braking device 2, a coupler buffer device 3, and is symmetrically arranged at the left and right lower ends of the car body 1 with the car body 1 as the central axis. The bogie 4, such as Figure 12 As shown, the brake device 2, the coupler buffer device 3 and the bogie 4 all adopt existing products.

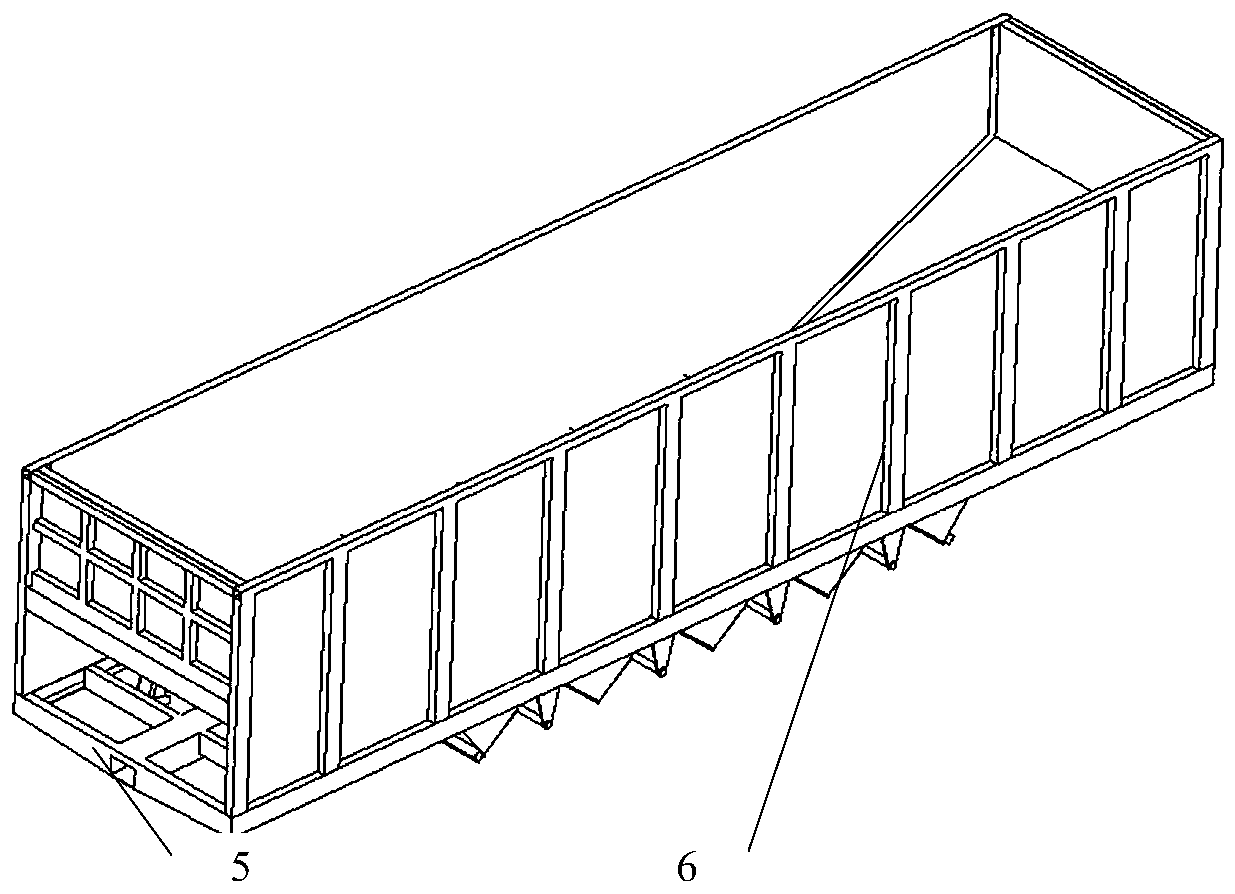

[0032] Described car body 1 comprises chassis 5, the side wall 6 that is arranged on the front and rear ends of chassis 5 respectively, the end wall 7 that is arranged on the left and right ends of chassis 5, is arranged on the material discharging opening in the middle of chassis 5 and cooperates with the discharge opening. The bottom door device 8 of the material opening, the material discharge opening is arranged between the two bogies 4, any one of the end walls 7 includes a first end plate 7.3 that is inclined to match the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com