Alkali slag concrete construction method

A construction method and concrete technology, applied in construction, construction material processing, building construction, etc., can solve problems such as reducing construction efficiency, increasing environmental pollution, and large shrinkage, so as to improve construction efficiency, avoid material waste, and improve Effect of pour quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

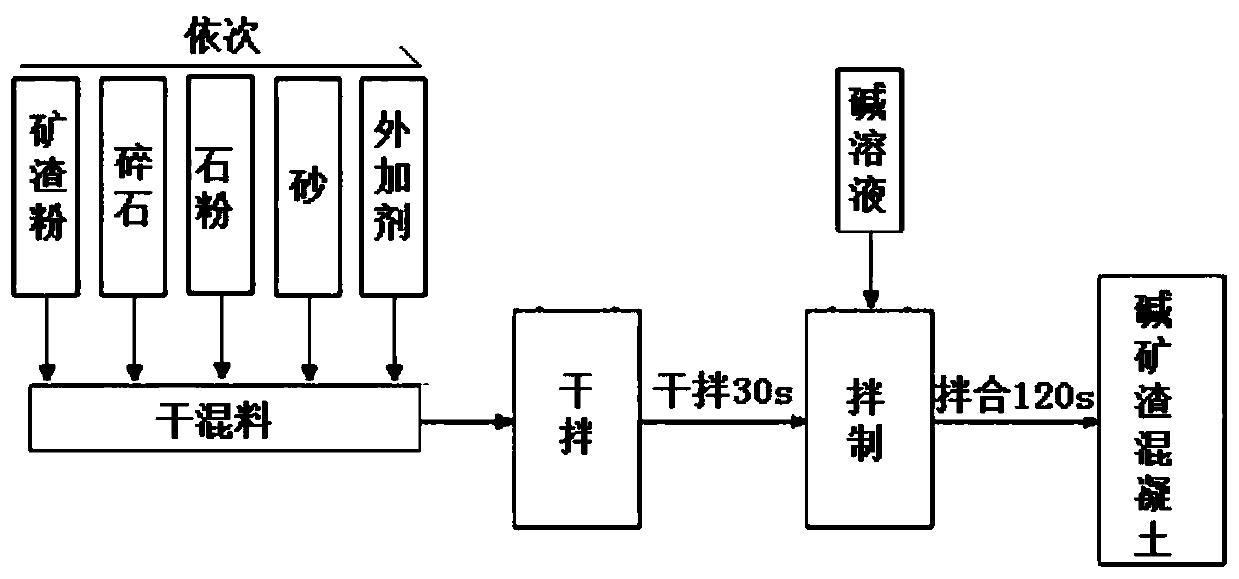

Method used

Image

Examples

Embodiment

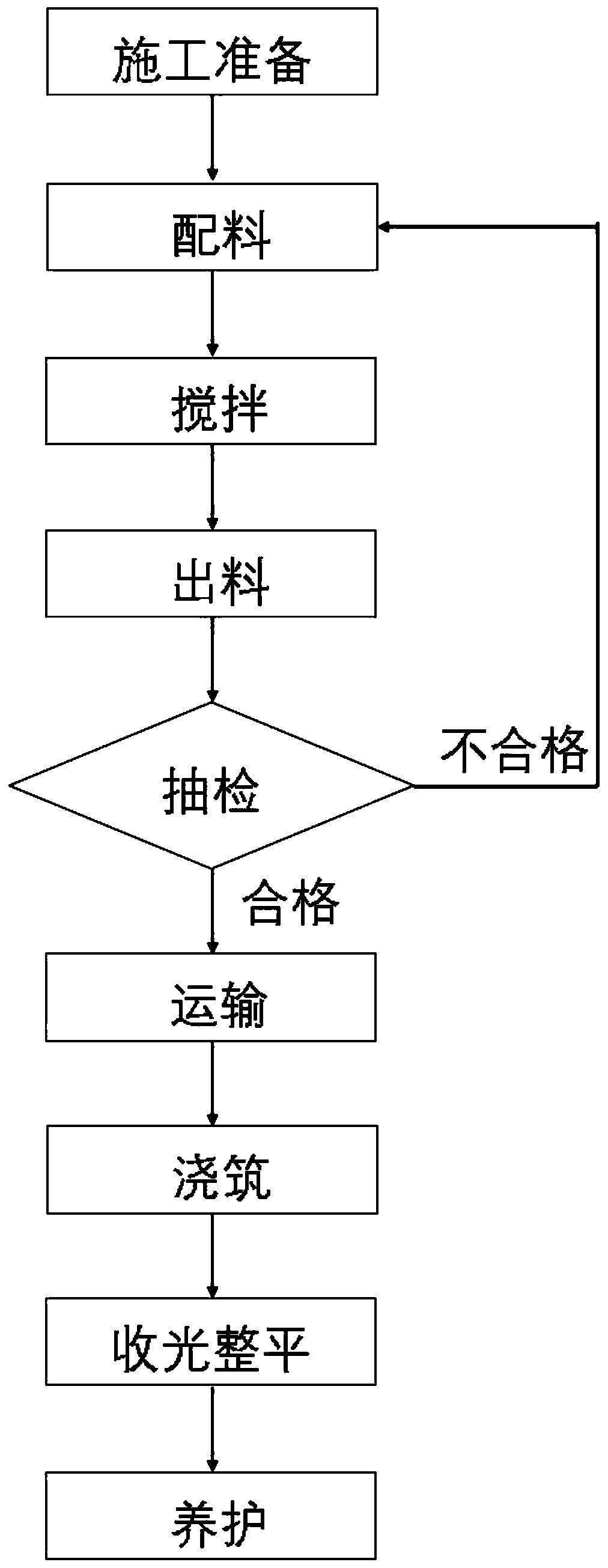

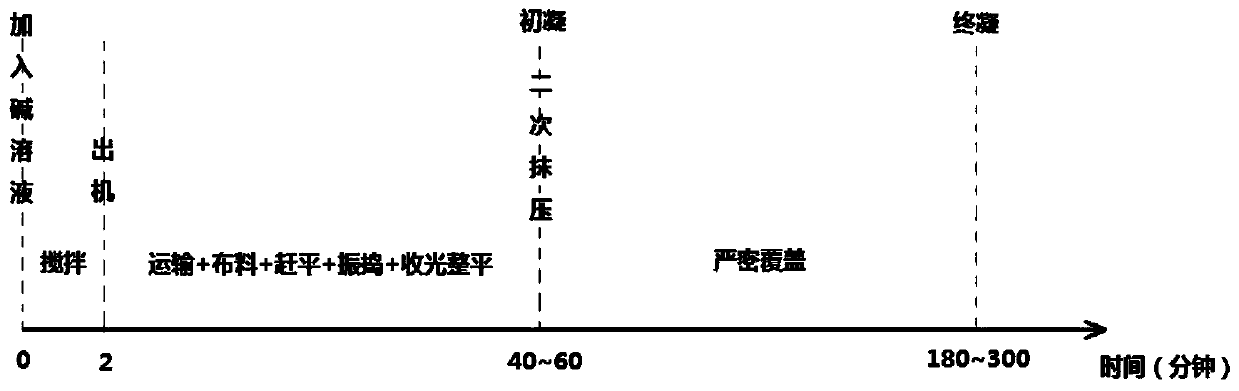

[0022] like figure 1 Shown, the embodiment of the present invention is as follows:

[0023] 1Construction preparation

[0024] Technical preparations: site layout principles: equipment that generates noise, dust and volatile gases should be kept away from residential areas as much as possible. The mixer should be covered with a soundproof board room and the alkali solution storage tank should be specially designed for automatic batching and circulation heating devices.

[0025] Material preparation

[0026] 1. Prepare the material entry plan according to the design mix ratio and pouring plan, and the materials will enter the site 1d ahead of schedule.

[0027] 2. When the sand and gravel enter the site, check the moisture content of the sand and gravel, propose the construction mix ratio, and calculate the amount of materials per tray. The reference ratio of C40 is as follows:

[0028]

[0029] 3. Trial mix is carried out according to the construction mix ratio and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com