Method for preparing low-temperature phase-change material from tetradecane and expandable graphite

A technology of expanded graphite and low-temperature phase change, which is applied in chemical instruments and methods, heat exchange materials, and other chemical processes. It can solve problems such as high cost and complex process of low-temperature phase change materials, and achieve low cost and ensure stable adsorption. Sex, the effect of long exothermic time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

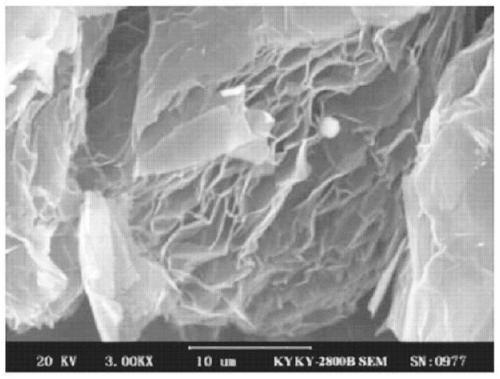

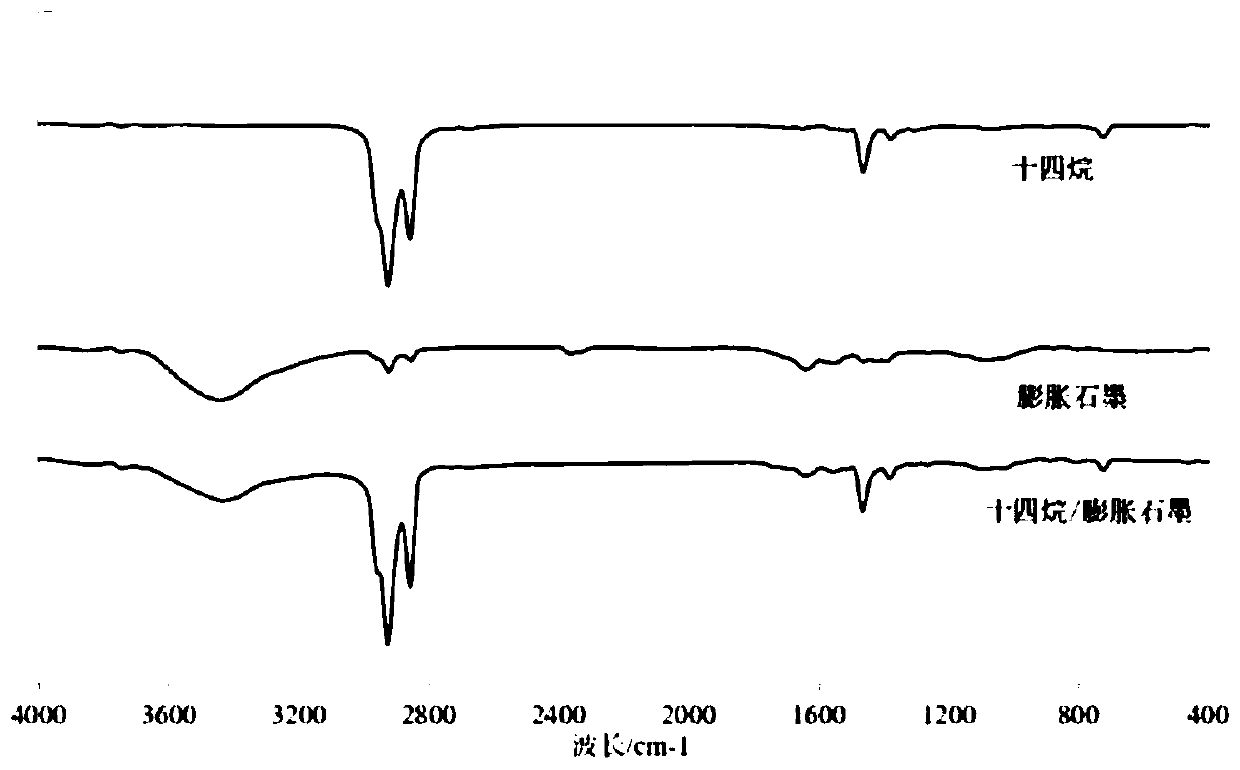

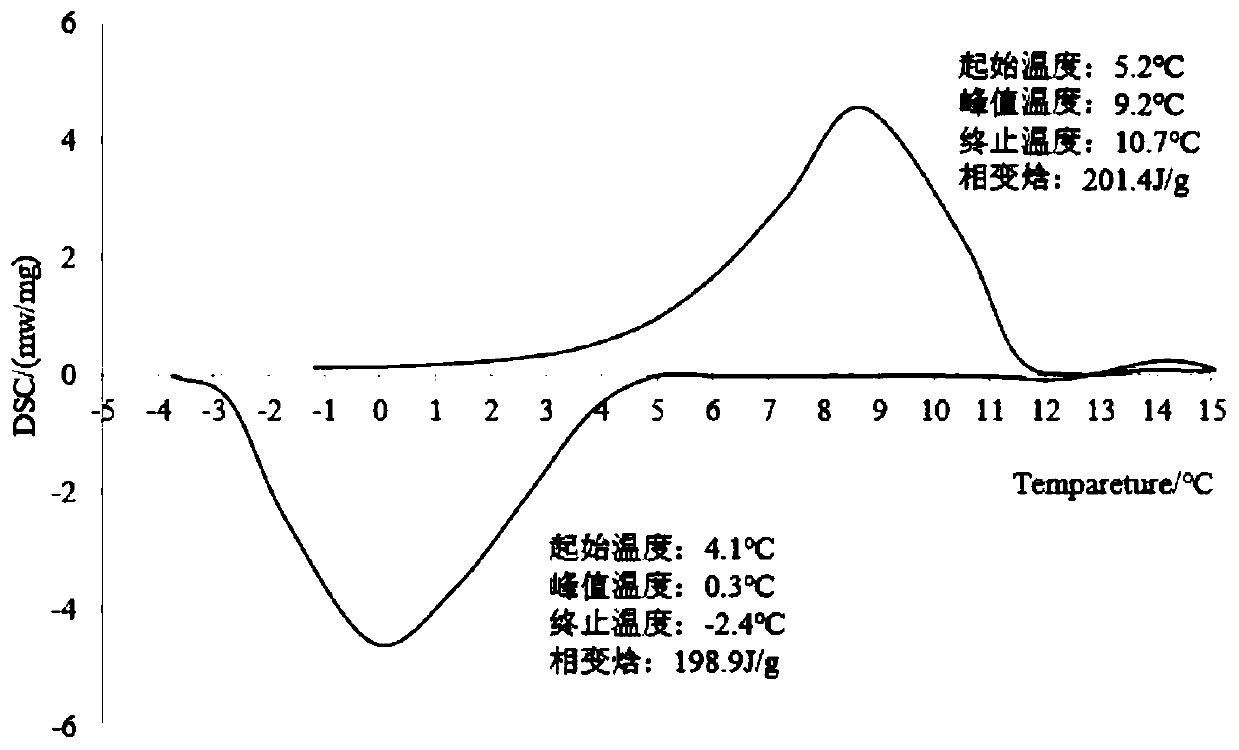

[0027] A method for preparing a low-temperature phase change material based on tetradecane / expanded graphite proposed by the present invention, the expandable graphite is placed in an oven and dried for several hours, then taken out and spread in a crucible, and the crucible is placed in a muffle furnace Calcinate for a period of time, take it out and cool it, and then prepare expanded graphite with complete expansion; the melting point of tetradecane used is 5.5°C, mix tetradecane / expanded graphite in a certain ratio, stir at a certain temperature and a certain pressure range, Make the two materials fully contact, absorb completely, mix evenly, pour the mixture into the funnel, connect the vacuum pump and carry out suction filtration until there is no liquid dripping from the bottom of the funnel, rinse the beaker with the filtrate repeatedly and suction filtration until there is no expanded graphite residue in the beaker. Put the solid obtained by suction filtration into an o...

Embodiment 1

[0035] (1) Put the expanded graphite in an oven at 100°C for 2 hours and fully dry it.

[0036] (2) Weigh 10 g of fully dried expanded graphite and add it to a beaker, pour the phase change main material into it to completely submerge the expanded graphite. Place the beaker in a 60°C water bath, stir with a constant speed stirrer at a speed of 160 rad / min for 30 minutes, during which the expanded graphite that sticks to the wall of the beaker should be scraped off to ensure full contact and complete adsorption of the material.

[0037] (3) Pour the homogeneous mixture that has been stirred into a funnel, connect a vacuum pump and carry out suction filtration until no liquid drips down at the bottom of the funnel, repeatedly rinse the beaker with the filtrate and perform suction filtration until there is no expanded graphite residue in the beaker.

[0038] (4) Put the solid obtained by suction filtration into an oven at 80° C. for blast drying, take it out and weigh it every ha...

example 2

[0047] Example 2: Same as Example 1, but the temperature of the water bath in step (2) is changed to 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com