Method for using hot compress wax paste blocks

A mud block and hot compress technology, which is applied in the field of health care, can solve the problems such as the inability to re-use the medicinal effect, the uncontrollable temperature of the wax mud spread, and the brittleness, so as to prolong the continuous heat release time, shorten the cooling and solidification time, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of using method of hot compress wax clay block is:

[0026] First, put 500 grams of hot compress wax clay in a glass bowl into the microwave for 3-5 minutes, so that the wax clay melts into a liquid state.

[0027] Then, pour the hot wax clay that melted into liquid into the rubber mold, and wait for the wax clay to cool down to a paste.

[0028] Then, put the rubber mold containing the hot compress wax mud upside down on the human skin, so that the rubber mold is wrapped on the back of the wax mud, and remove after 40 minutes of hot compress on the part of the human body to be healthy;

[0029] The improvement of the operation method shortens the cooling and solidification time of the wax slime in the original operation method, effectively prolongs the continuous heat release time of the wax slime, and the covering of the rubber thin mold reduces the heat loss of the wax slime and prevents the clothes from being polluted at the same time.

[0030] Finally, sepa...

Embodiment 2

[0032] A kind of using method of hot compress wax clay block is:

[0033] First, put 500 grams of hot compress wax clay in a glass bowl into the microwave for 3-5 minutes, so that the wax clay melts into a liquid state.

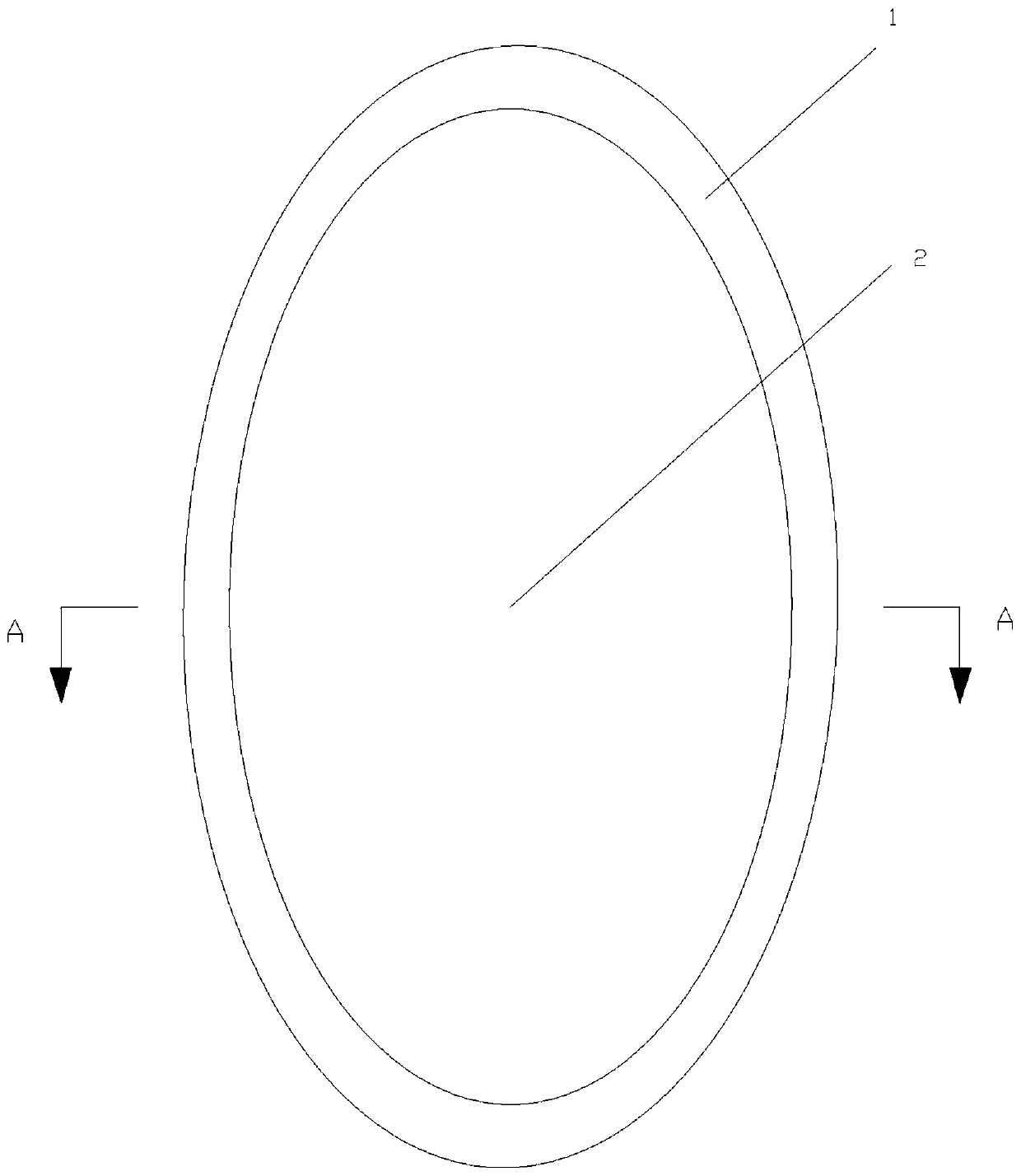

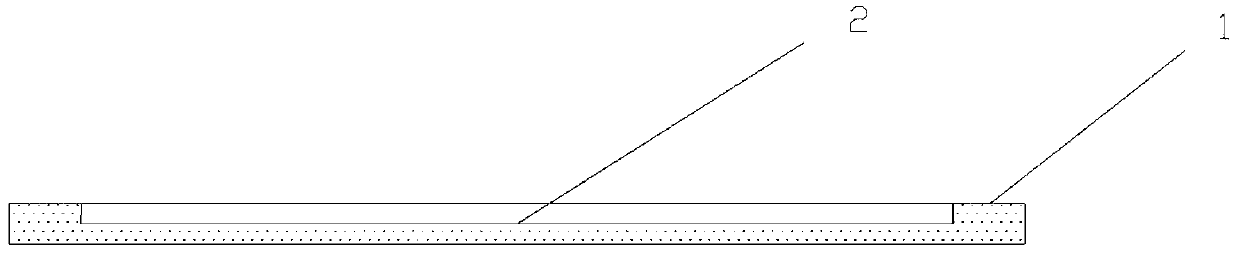

[0034] Then, pour the hot compress wax slime that has melted into a liquid into the rubber mold, and wait for the hot compress wax slime to cool to a paste; figure 1 and figure 2 As shown, the rubber mold has an elliptical structure, which has an edge 1 of 8mm, and has an oval groove 2 inside, and the depth of the groove is 1.5mm; The wax slime covers the groove 2, and part of the hot compress wax slime overflows to the edge 1, which increases the hot compress area and makes it easier for the mud mold to separate.

[0035] Then, buckle the rubber mold containing the hot compress wax mud upside down on the human skin, so that the rubber mold is wrapped on the back of the wax mud, and remove after 40 minutes of hot compress on the part of the human body to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com