Nanocomposite energy storage ball and preparation method thereof

A nano-composite and nano-composite material technology is applied in the field of nano-composite energy storage balls and their preparation, which can solve the problems of low energy storage density of sensible heat energy storage systems, bulky equipment, and inability to store heat at a constant temperature, and achieve large heat release. , The effect of high energy storage density and long heat release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments.

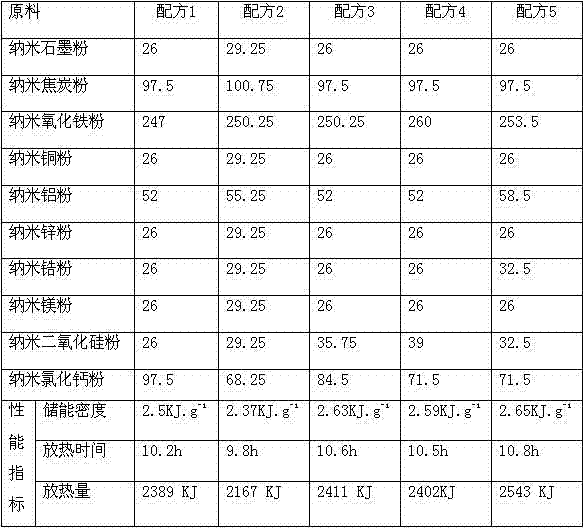

[0020] In 1000 grams of nanocomposite energy storage balls, first prepare 650 grams of nanocomposite materials, weigh the raw materials according to the following formula, and put the raw materials into a mixing tank to fully mix and stir evenly:

[0021] Unit: grams

[0022]

[0023] Fully mix the prepared 650 grams of nanocomposite material with 350 grams of refractory material, stir evenly, prepare a nanocomposite energy storage ball suitable for the size of the hotel stove burner according to the size of the hotel stove burner, and dry it at room temperature .

[0024] Among them, the refractory material is made of 80-90% refractory mud and 10-20% refractory cement; preferably 85% refractory mud and 15% refractory cement.

[0025] The effect of preparing nano-energy storage balls with the formulas described in the above table is equivalent, and the effect of formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com