Pouring process for carrying out tunnel secondary lining through novel hydraulic trolley

A technology for hydraulic trolleys and tunnels, applied in tunnel linings, tunnels, shaft linings, etc., can solve the problems of time-consuming, labor-intensive, and heavy workload, and achieve the effect of speeding up construction progress, improving work efficiency, and eliminating tedious work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

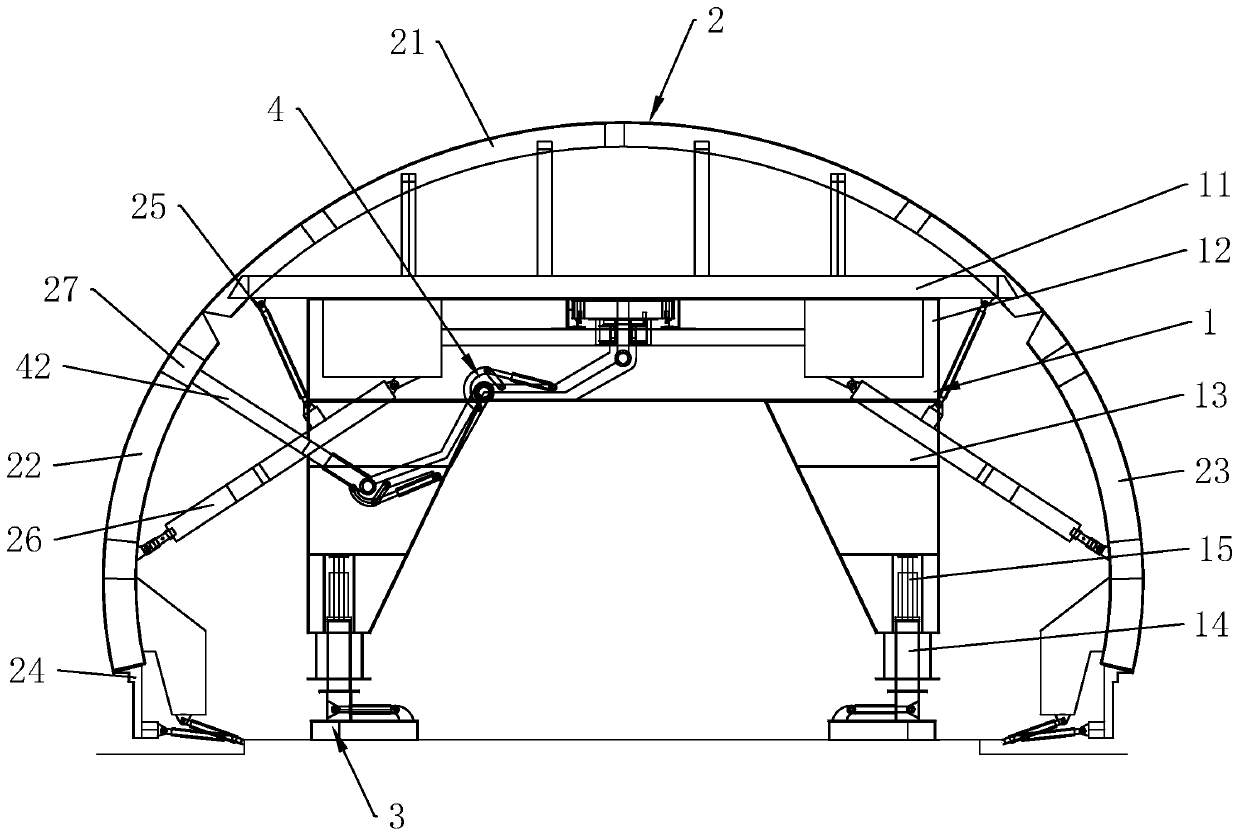

[0045] refer to figure 1 , is a new type of hydraulic trolley disclosed by the present invention, including a mast system 1 , a formwork system 2 , a walking system 3 and a material distribution system 4 .

[0046] refer to figure 1 , the gantry system 1 comprises an upper beam 11, a gantry girder 12, a gantry column 13 and a lower longitudinal beam 14, wherein the gantry girder 12 is arranged horizontally, the upper beam 11 is welded and fixed on the top of the gantry girder 12, and the gantry column 13 is provided with four, which are respectively welded and fixed at the four corners of the bottom of the mast girder 12. The lower longitudinal beams 14 are horizontally arranged on both sides below the mast girder 12, and the four mast columns 13 and the lower longitudinal beams 14 are all fixed. A lifting oil cylinder 15 is installed, and the end of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com