Electric grounding pile for electric power engineering

A technology of electric power engineering and grounding piles, which is applied in the field of electric power grounding piles for electric power engineering, which can solve the problems of hidden dangers in line safety operation, easy to be pulled out by external force, high maintenance cost, etc., achieve good fixing effect, not easy to pull out, and reduce maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

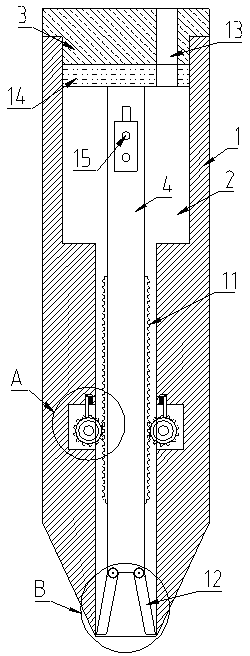

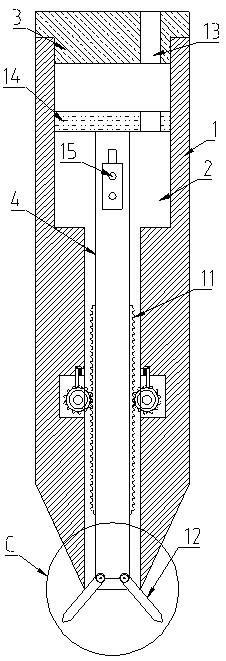

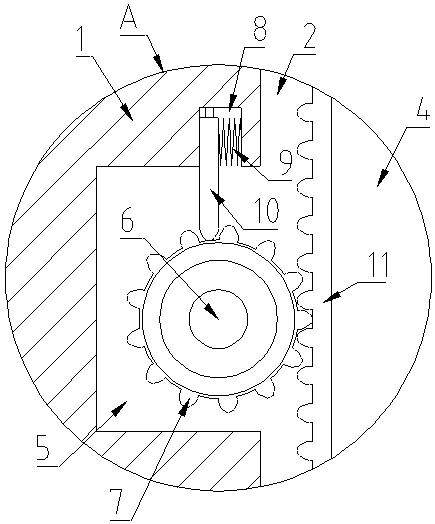

[0022] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a power grounding pile for electric power engineering includes a grounding pile body 1, a cavity 2, a plugging head 3, a push rod 4, an accommodating groove 5, a rotating shaft 6, a gear 7, a groove 8, a spring 9, a limiter Bit plate 10, rack plate 11 and elastic plate 12.

[0024] Wherein, the bottom of the ground pile body 1 can be set as an inverted conical structure, and the inside of the ground pile body 1 is provided with a cylindrical cavity 2 that runs through its height direction, and the cavity 2 can also be set from top to bottom. The stepped cylindrical structure with lower diameter successively decreases, which is convenient for positioning. The top of the grounding pile body 1 is provided with the plugging head 3, and the plugging h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com