Accurate quantity air-suction seed taking device capable of changing row spacing and operation method

A technology of line spacing and precision, applied in the field of precision gas suction seed devices, can solve the problems of uneven air distribution, poor universality of suction cups, etc., and achieve the effects of simple control method, high reliability and improved synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

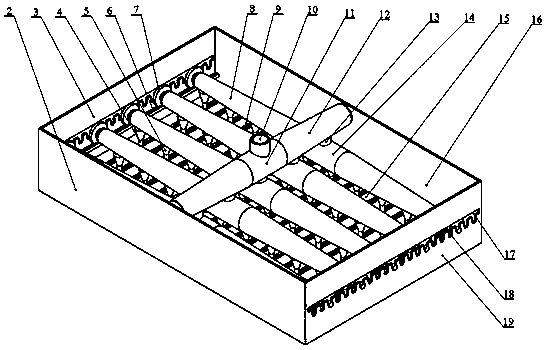

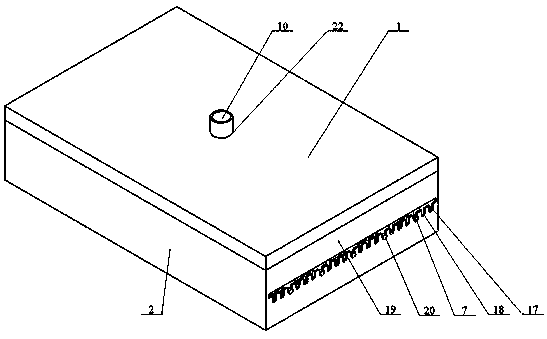

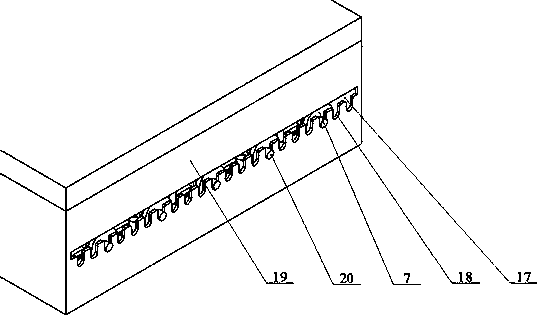

[0036] Reference Figure 1-7 , A variable row spacing precision air suction device, including a housing, a branch pipe and a suction assembly 28, the housing upper top plate 1, lower bottom plate 15, front plate 2, rear plate 16, left side plate 3 and right The side plate 19 is composed of a row spacing adjustment mechanism on the left side plate 3 and the right side plate 19. The branch pipe is composed of a primary branch pipe 26 and a secondary branch pipe 27. The primary branch pipe 26 passes through the hose 13 and the secondary The shunt pipe 27 is detachably connected. The first shunt pipe 26 is fixedly connected to the inner wall of the shell. The first shunt pipe 26 is composed of a straight pipe section I11 and two sets of tapered pipe sections I12. The two sets of tapered pipe sections I12 are respectively fixedly connected to two of the straight pipe sections I11. The top of the straight pipe section I11 is fixedly connected with an air source interface 10, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com