A precision air suction seed device and operation method with variable line spacing

A row-spacing and precision technology, applied in the field of precision air suction devices, can solve the problems of poor versatility of the suction cup and uneven air distribution, and achieve the effects of high reliability, simple control method and simple structure

Active Publication Date: 2022-06-03

BINZHOU UNIV +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the defects of uneven air distribution and poor versatility of suction cups in the prior art, and propose a variable row-spacing precision air suction seed device and operation method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

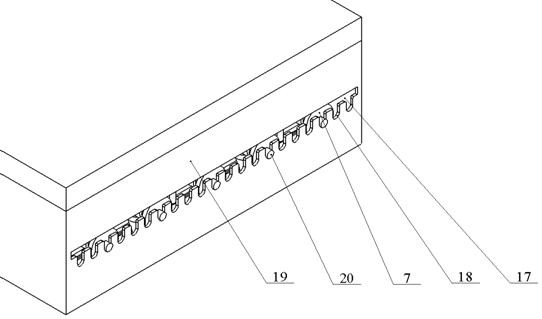

[0039] The bottom of the straight pipe section I11 and the tapered pipe section I12 are all provided with a connecting hole I, and the top of the straight pipe section II14 is provided with a connecting hole.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

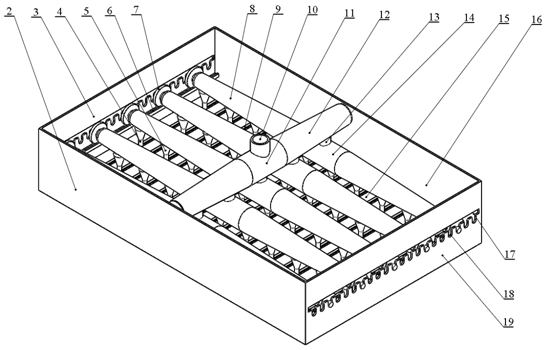

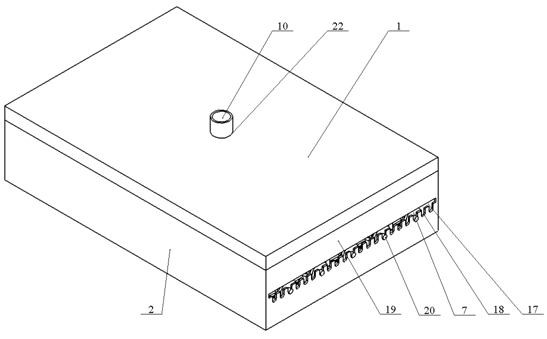

The invention discloses a precision air suction seed device and an operation method with variable row spacing, and belongs to the technical field of sowing agricultural machinery. A precision air suction device with variable line spacing, including a housing, a distribution pipe and a suction assembly. The housing is provided with a row spacing adjustment mechanism. It is connected with the secondary distribution pipeline, the primary distribution pipeline is connected in the shell, the primary distribution pipeline is composed of straight pipe section I and two sets of tapered pipe sections I, two sets of tapered pipe sections I are connected at both ends of straight pipe section I, and straight pipe section I The air source interface and the secondary distribution pipeline are composed of a straight pipe section II in the middle and two sets of tapered pipe sections II. In cooperation, the suction components are evenly distributed at the bottom of the secondary distribution pipeline; the present invention utilizes the variable number and diameter of the secondary distribution pipeline to adjust the air pressure level and versatility.

Description

A precision gas suction seed device and operation method with variable row spacing technical field The present invention relates to sowing agricultural machinery technical field, relate in particular to a kind of precision gas suction seed device of variable row spacing and working methods. Background technique In recent years, along with the development demands of cultivation operations such as rice seedling raising, vegetable seedling raising and precision sowing of wheat, air-suction type Sowing technology is used more and more widely in the sowing operation of precision agriculture, and its core technology is concentrated in air-suction precision seed picking. on the device. At present, there are three types of air-suction precision seed pickers: air-suction drum type, air-suction whole disc type and suction-needle type. The seed picker has the advantages of no seed damage, high hole alignment accuracy, high single-grain rate, and good seed suction and discharge...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A01C7/08

CPCA01C7/082A01C7/084Y02P60/20

Inventor 赵新学张爱民郝延杰李明军廖培旺王彪

Owner BINZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com