Tea pile turning system and control method thereof

A control method and tea technology are applied to the tea pile turning system. The control field of the system can solve the problems of high labor intensity, easy sweating, and limited space utilization, and achieve the effects of good effect, reliable use and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments, but this does not constitute any limitation to the present invention.

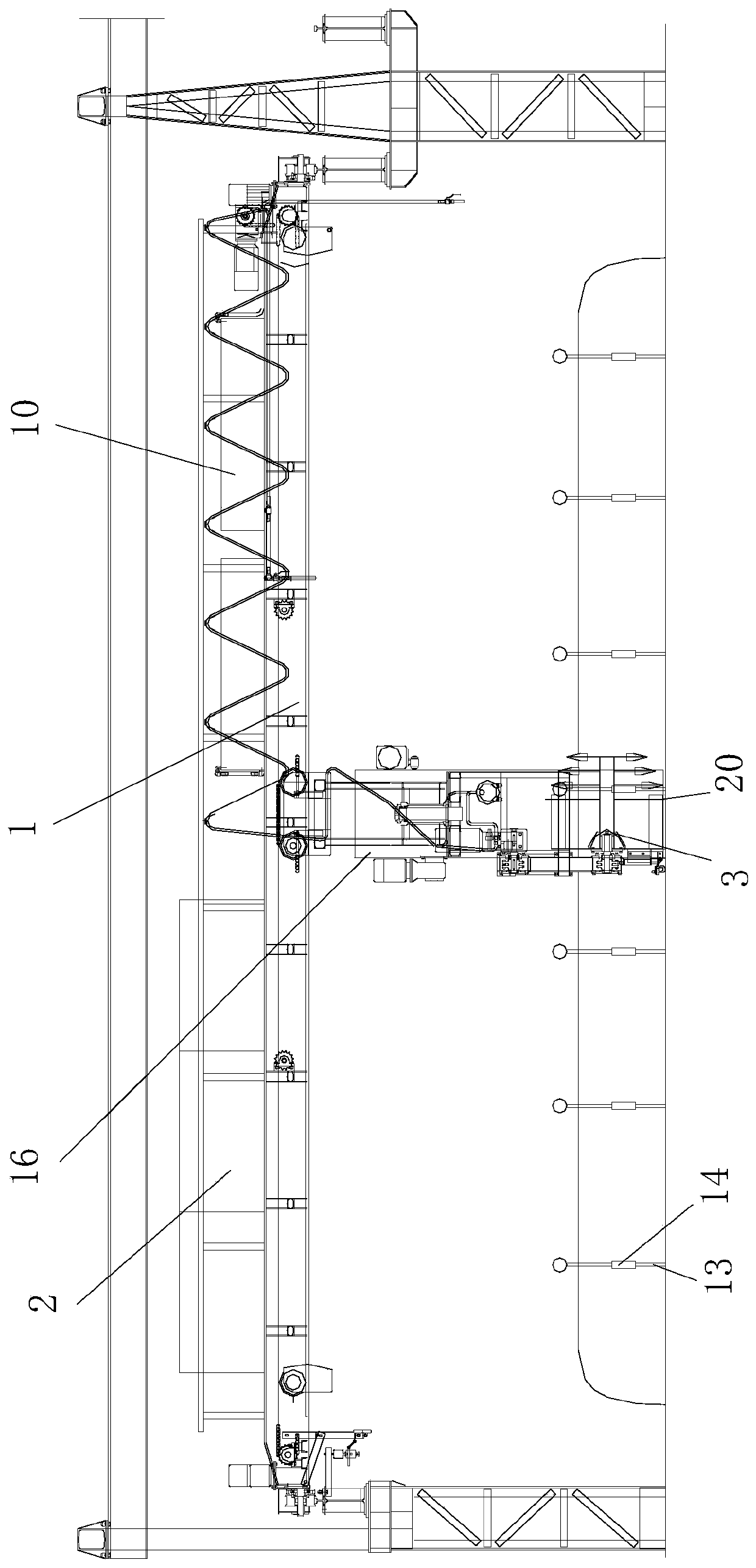

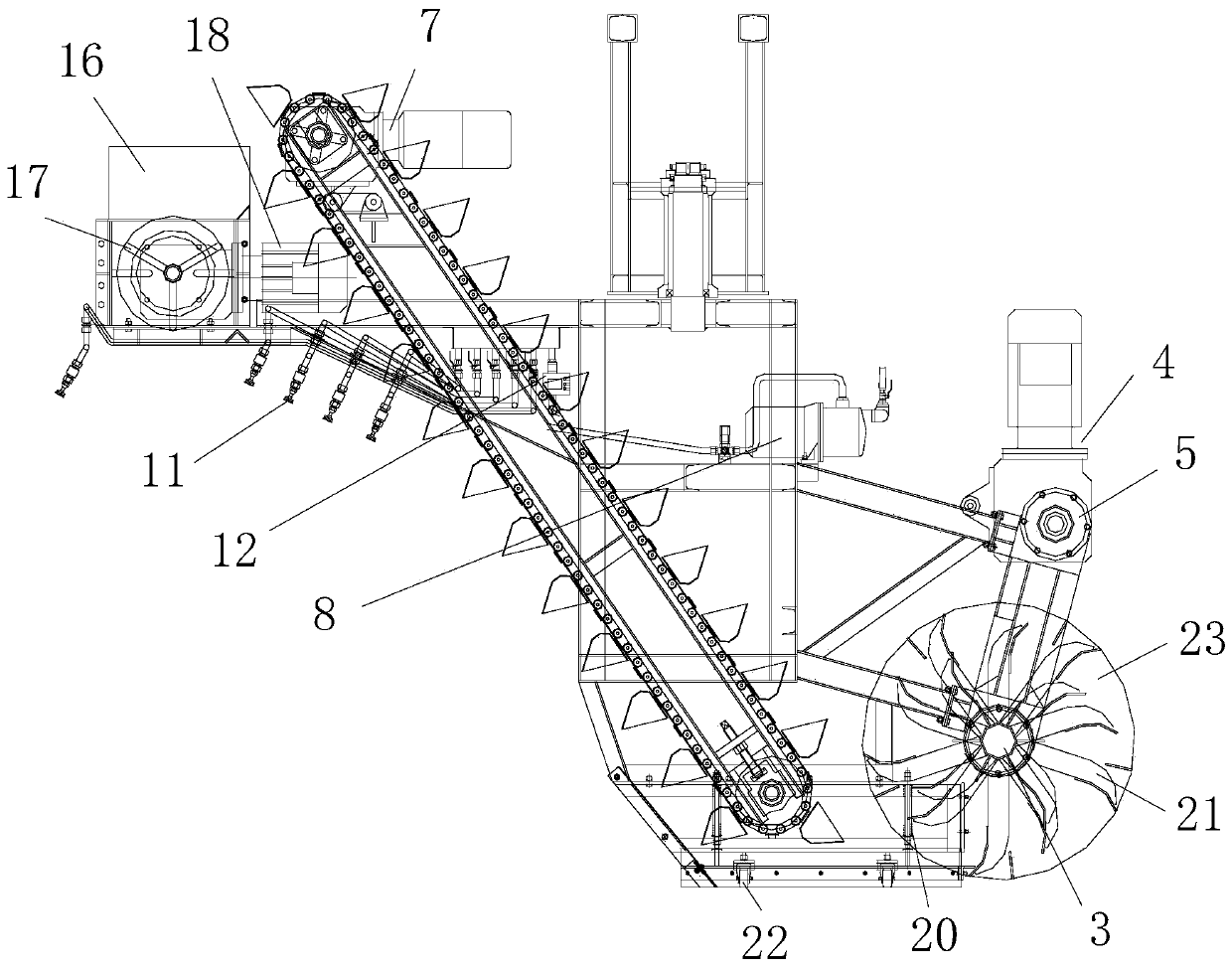

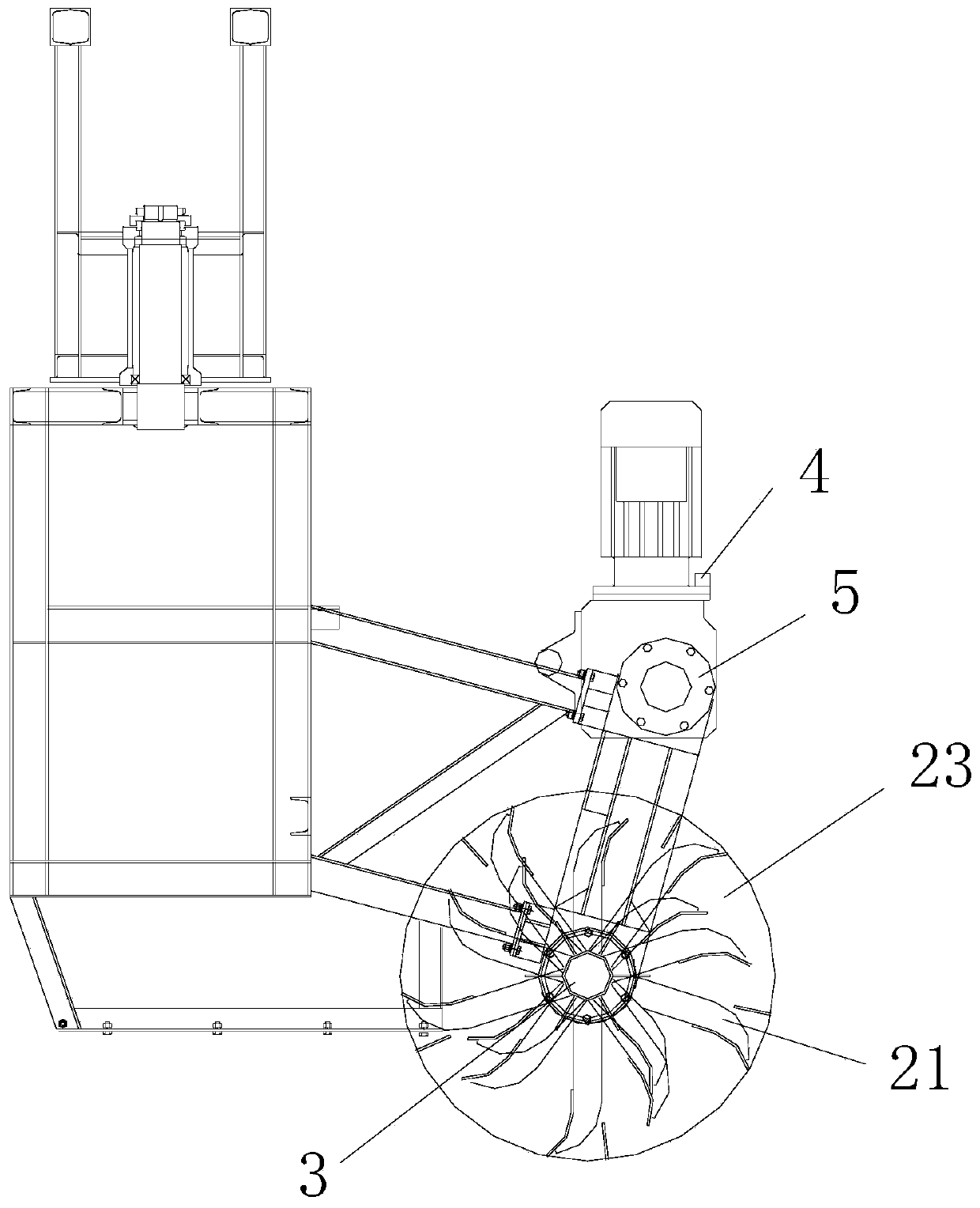

[0030] refer to Figures 1 to 4As shown, a tea leaf turning system of the present invention includes a bridge frame 1 capable of walking longitudinally and laterally, the bridge frame 1 is provided with a rotating mechanism and a control system 2, and the rotating mechanism is provided with a turning mechanism. For the tea machine, the rotating mechanism can change the working direction of the tea turning machine, and is connected with the control system 2 to call different control programs. The tea turning machine includes a tea raking mechanism, a tea turning mechanism, a deblocking mechanism and a spraying mechanism. The tea raking mechanism includes a runner 3 arranged at the bottom of the bridge frame 1, and the runner 3 is provided with a distance Inductor 4 and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap