Liquid-tight vacuum chuck and its adsorption method

A vacuum suction cup and liquid sealing technology, applied in suction cups, connecting components, mechanical equipment, etc., can solve the problems of insufficient suction cup adsorption, and achieve the effects of small size, convenient installation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

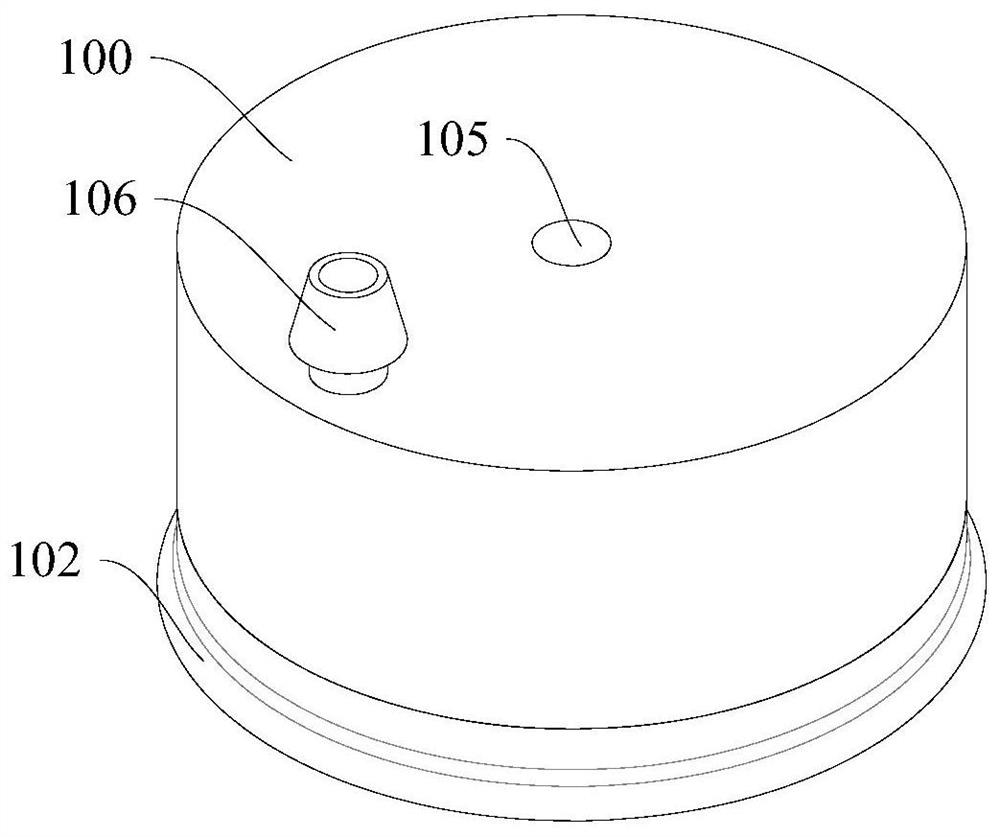

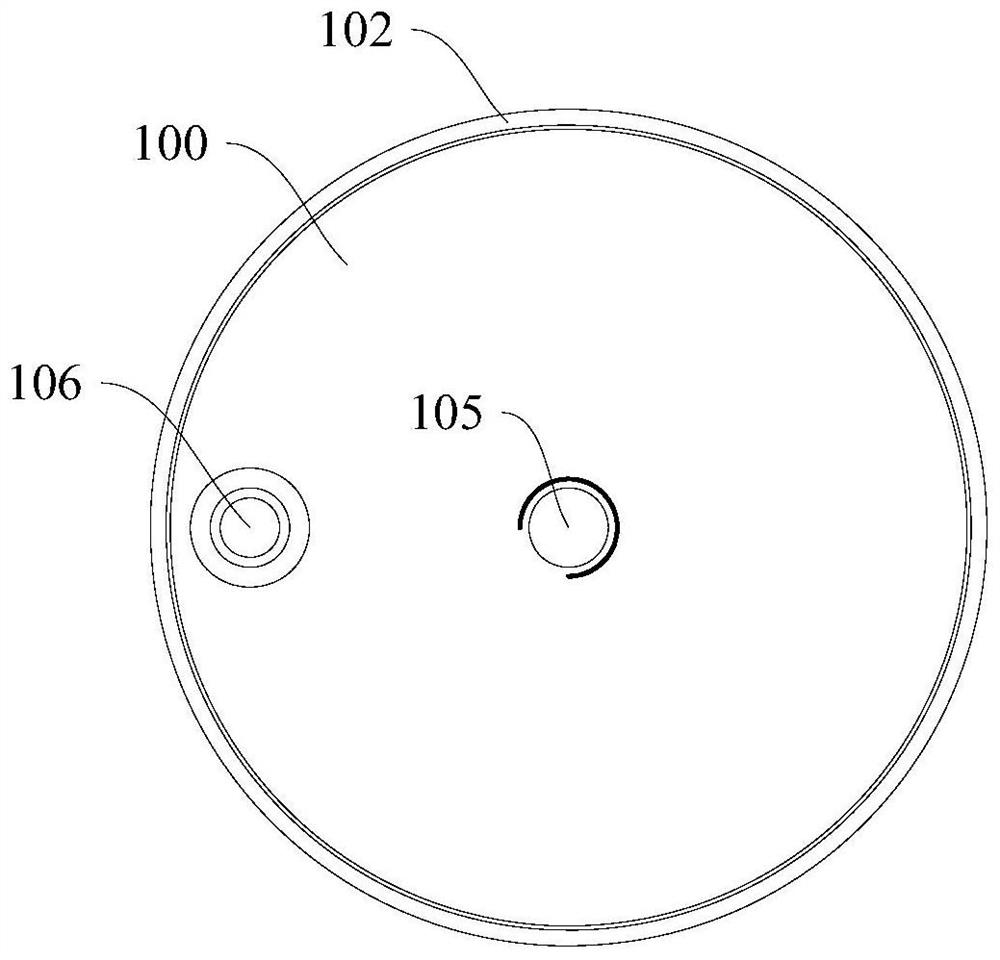

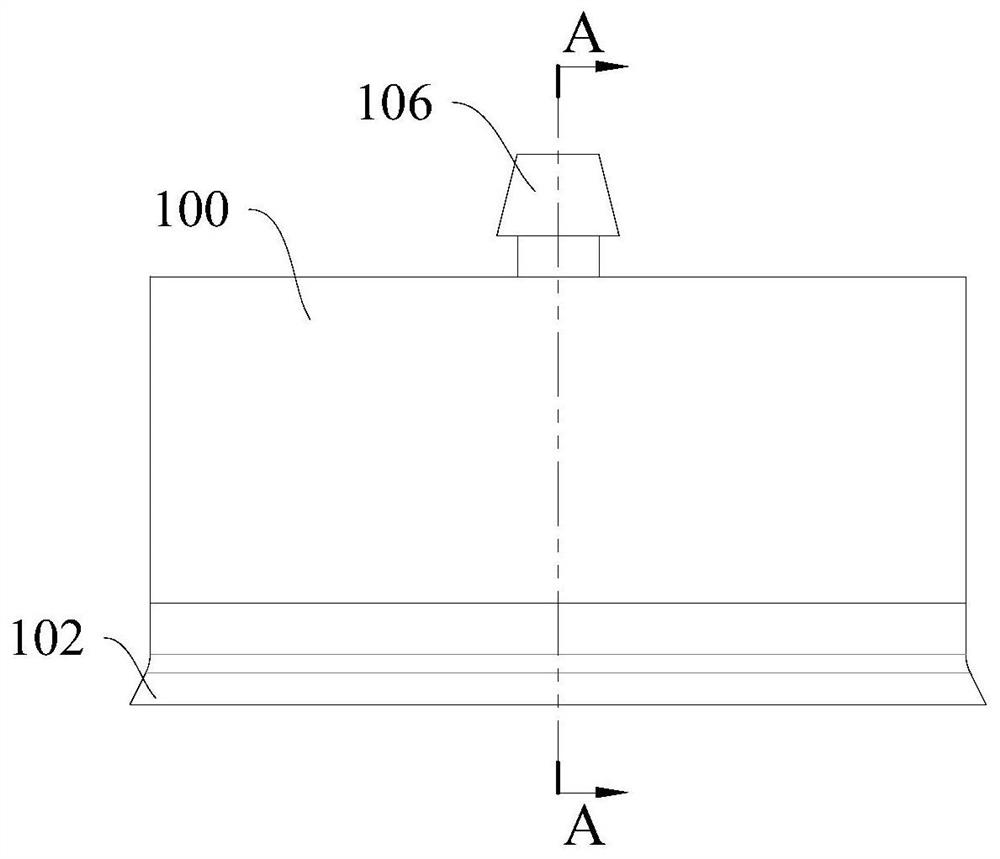

[0030] see Figure 1 to Figure 5 , the liquid-tight vacuum chuck based on the present embodiment includes a suction cup body 100, the suction surface of the suction cup body 100 is provided with an inner sealing ring 101 and an outer sealing ring 102, and the suction cup body 100 is provided with a liquid storage chamber 103 and a vacuum chamber 104. The top of the body 100 is provided with a quick connector threaded hole 105 connected to the vacuum chamber 104 and a liquid external nozzle 106 connected to the liquid storage chamber 103 .

[0031] The liquid storage chamber 103 is an annular cavity, and an annular gap is formed between the inner sealing ring 101 and the outer sealing ring 102, and a circle of hole array 107 is arranged between the gap and the liquid storage chamber 103 for sealing the liquid storage chamber The liquid in 103 flows into the gap to improve the adsorption force.

[0032] The suction cup body 100 of this embodiment is manufactured by 3D printing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com