Method for centering roundness measuring frame of vertical shaft umbrella type hydro-generator rotor

A technology for hydroelectric generators and generator rotors, which can be used in hydroelectric power generation, manufacturing of motor generators, and mechanical measuring devices. It can solve problems such as uneven air gaps, reduce horizontal vibration, ensure safe and stable operation, and reduce air pollution. Gap inhomogeneity and the effect of unbalanced magnetic pull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

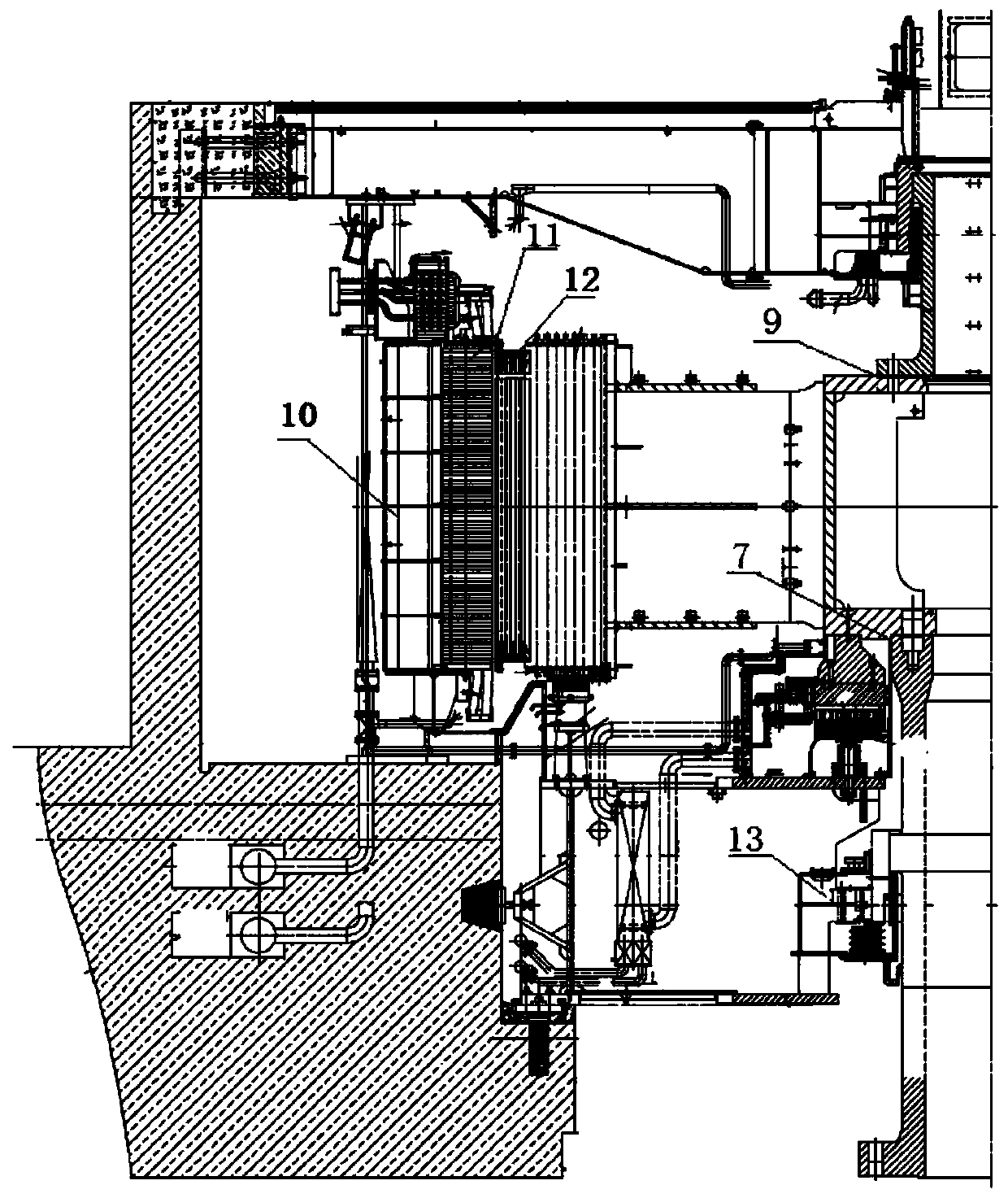

[0023] Before the cranking of the unit, carry out the speed change test of the unit, and record the air gap data of the generator stator and rotor of the unit when the speed range is 0-10r / min. The distance between the rotors; during the maintenance of the unit, manually measure the air gap data of the generator stator and rotor, that is, the minimum distance measured between the protruding position in the middle of the rotor magnetic pole and the stator is used as the air gap of the generator stator and rotor; when the two The comparison and verification of the air gap data of the stator and rotor of the secondary generator is normal, indicating that the results of the two measurement methods are valid, and the data basis for alignment based on the installation center of the lower guide bearing measured by the cranking of the unit is accurate before starting the following operations.

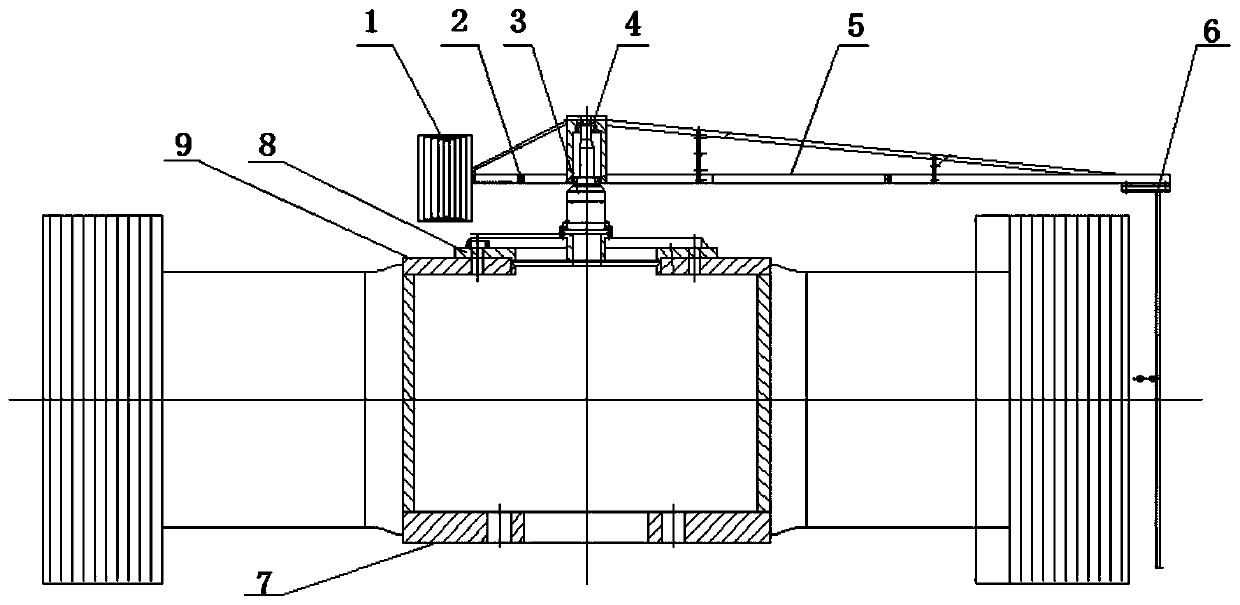

[0024] (1) Carry out cranking of the unit before dismantling, measure the installation cente...

Embodiment 2

[0032] (1) The air gap data of the generator rotor in the online monitoring system when the unit is running and the speed range is 0-10 r / min is compared with the manually measured data when the unit is overhauled and cranked, and the calibration is normal. Follow-up;

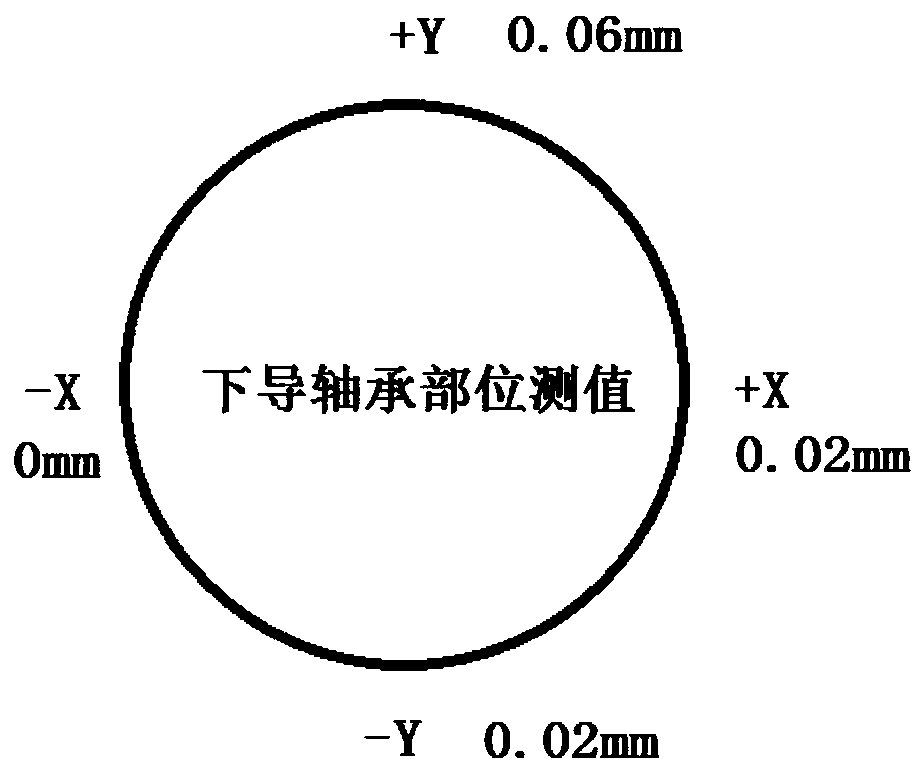

[0033] (2) Calculated from the cranking data, when the unit rotates, the rotation center of the lower guide bearing is offset by 0.06mm in the +Y direction relative to the installation center of the lower guide bearing (that is, the center of the lower flange of the generator rotor);

[0034] (3) It is measured by hanging the piano wire that the upper flange of the generator rotor is offset by 0.04mm in the -Y direction relative to the lower flange of the generator rotor (that is, -0.04mm in the +Y direction);

[0035] (4) According to the superposition calculation, the upper flange of the generator is offset by 0.02mm in the +Y direction relative to the rotation center of the lower guide bearing during operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com