Modularly-assembled artificial light seedling raising frame

A technology of artificial light and seedling racks, which is applied in the direction of planting beds, lighting devices, lighting auxiliary devices, etc., can solve the problems of inability to waste space resources, provide suitable light for seedlings, and adjust, so as to save the use of support materials and reduce power consumption. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

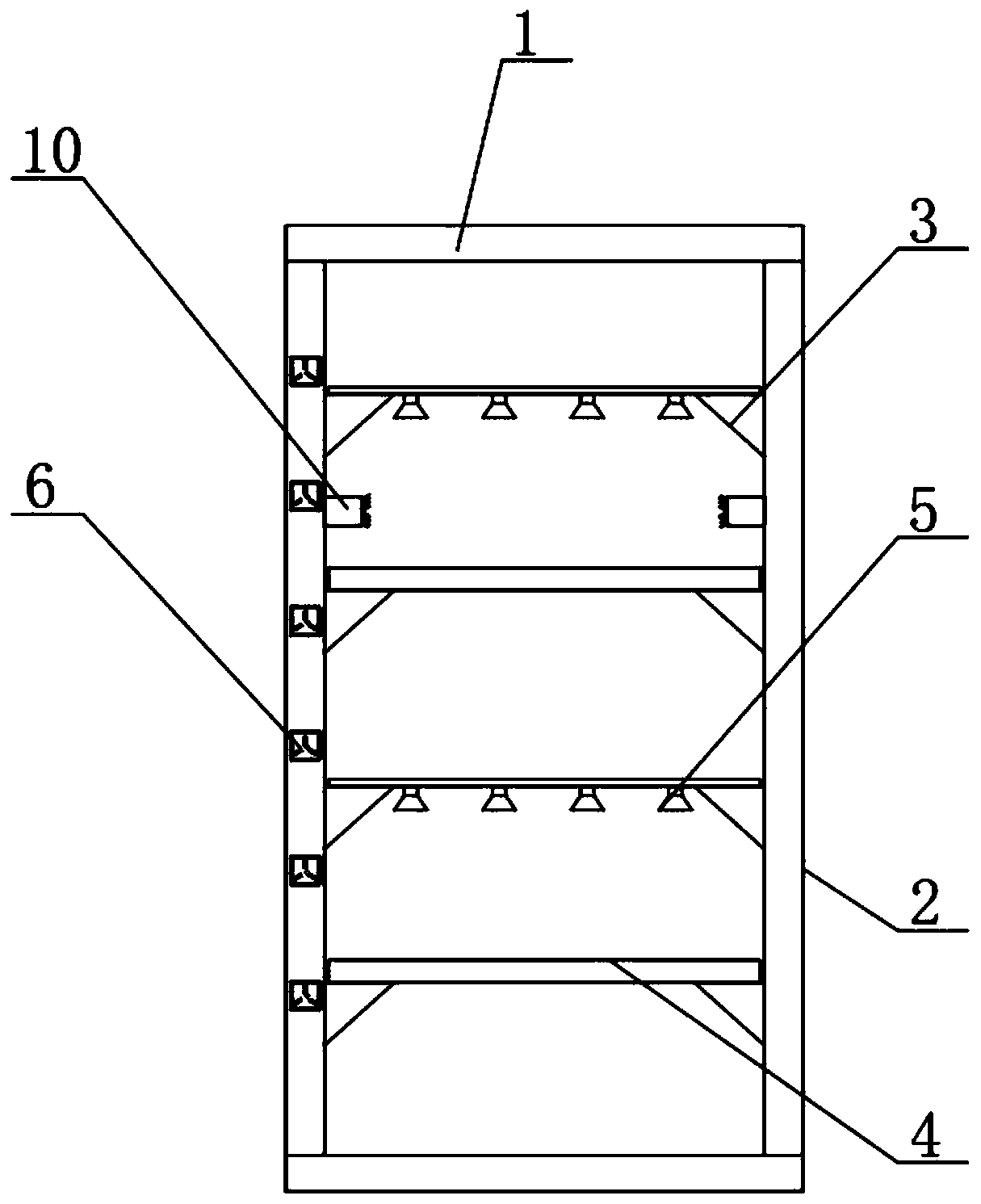

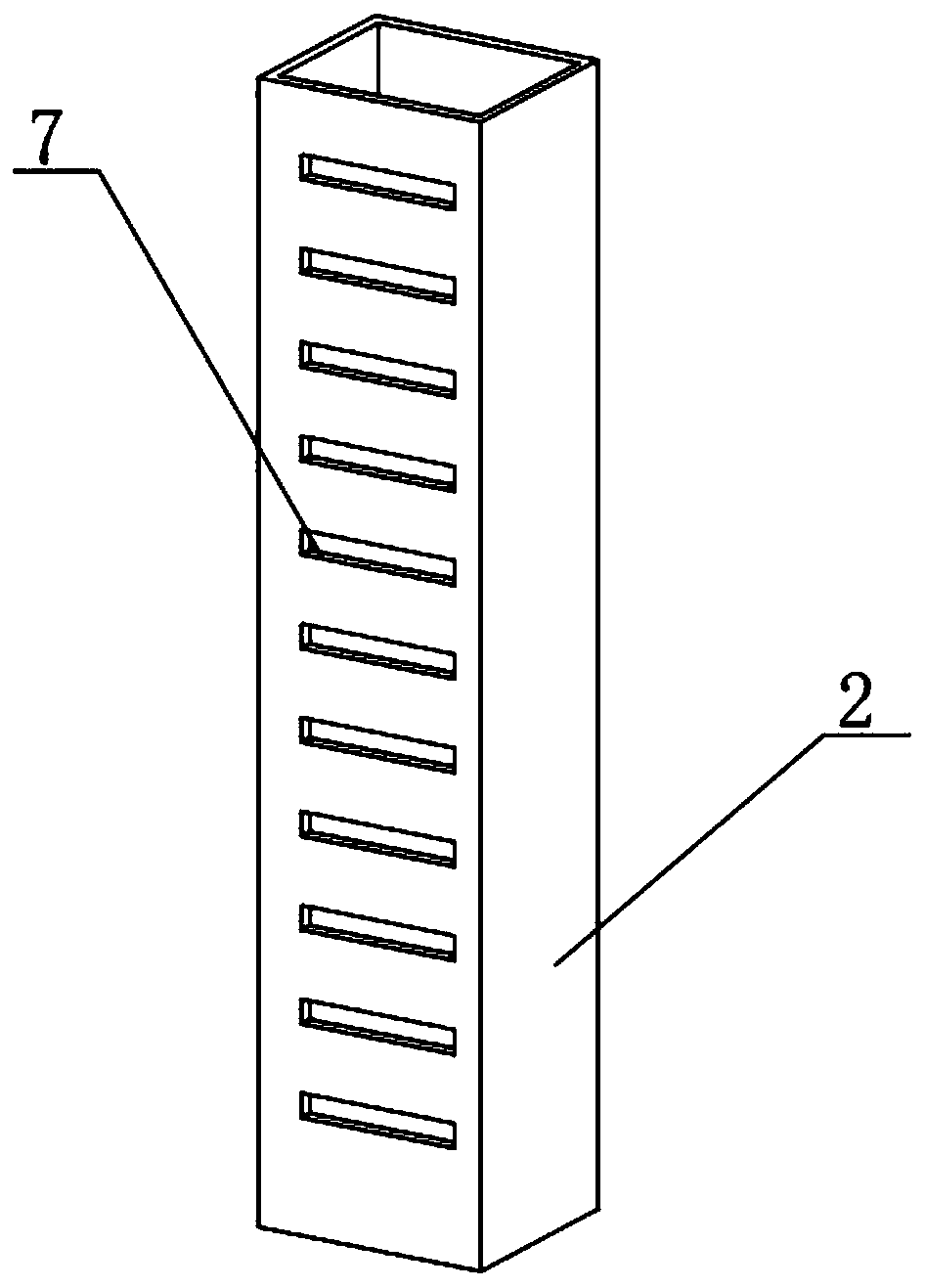

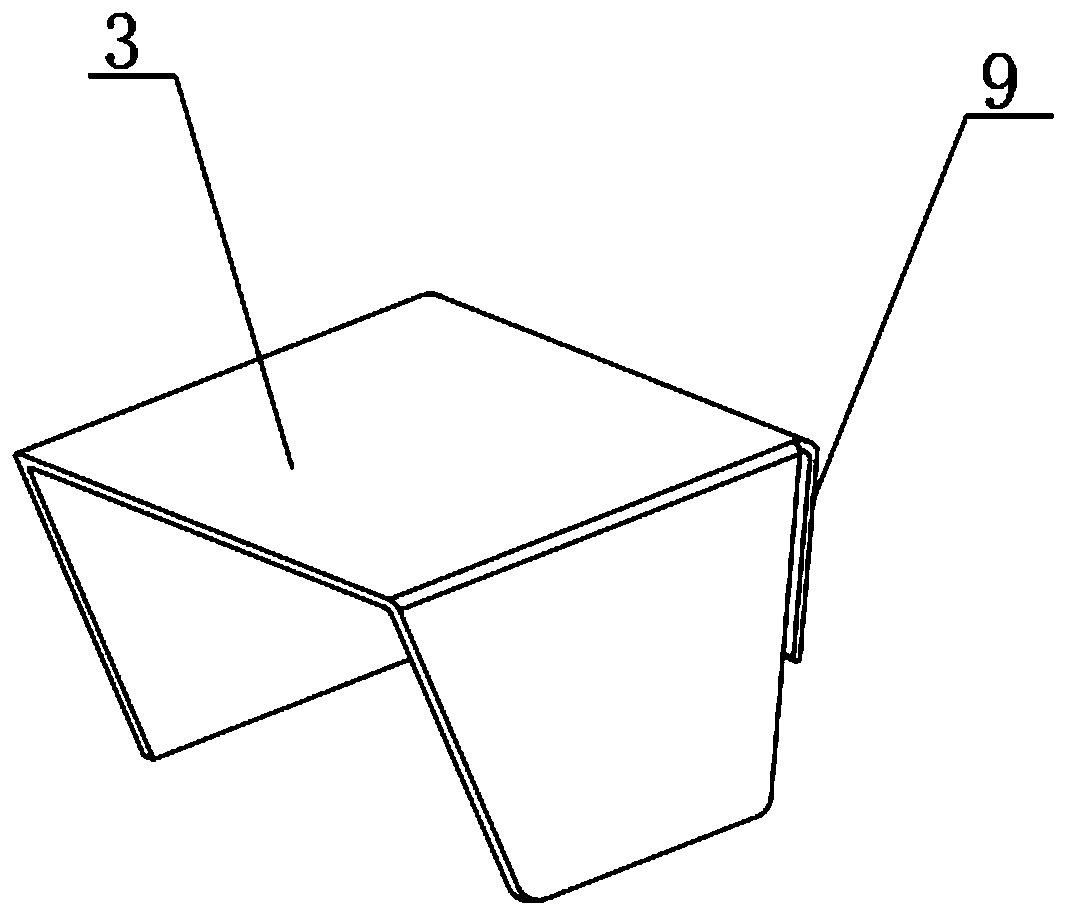

[0022] See Figure 1 to Figure 4 , The present invention provides a technical solution: a modular assembly artificial light seedling raising rack, including four equal support risers 2 and a single top plate 1, the bottom end of the top plate 1 is provided with a bottom for the four support risers 2 to insert Hole 8, the inner side of each support riser 2 is provided with a plurality of mounting holes 7, and the inner side of the support riser 2 is also provided with a plurality of triangular support frames 3, the setting of the triangular support frame 3 makes the seedling tray 4 position With the adjustment of the position of the light source 5, three-dimensional cultivation of plants of different plant types can be carried out, and the versatility is high. The rear surface of the triangular support frame 3 is fixed with a rear arc plate 9 and the rear arc plate 9 is clamped into the inner side of the mounting hole 7.

[0023] In this embodiment, preferably, the cross section o...

Embodiment 2

[0028] See Figure 1 to Figure 4 , The present invention provides a technical solution: a modular assembly artificial light seedling raising rack, including four equal support risers 2 and a single top plate 1, the bottom end of the top plate 1 is provided with a bottom for the four support risers 2 to insert Hole 8, the inner side of each support riser 2 is provided with a plurality of mounting holes 7, and the inner side of the support riser 2 is also provided with a plurality of triangular support frames 3, the setting of the triangular support frame 3 makes the seedling tray 4 position With the adjustment of the position of the light source, three-dimensional cultivation of plants of different plant types can be carried out, and the versatility is high. The rear surface of the triangular support frame 3 is fixed with a rear arc plate 9 and the rear arc plate 9 is clamped into the inside of the mounting hole 7.

[0029] In this embodiment, preferably, the cross section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com