Tobacco reconstituted tobacco cooling unit and cigarette comprising same

A technology for reconstituting tobacco leaves and cigarettes, applied in application, tobacco, cigar manufacturing, etc., can solve the problems of increased suction resistance, affecting smoking experience, easy collapse of phase change materials, etc. Rich and full, rich smoke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

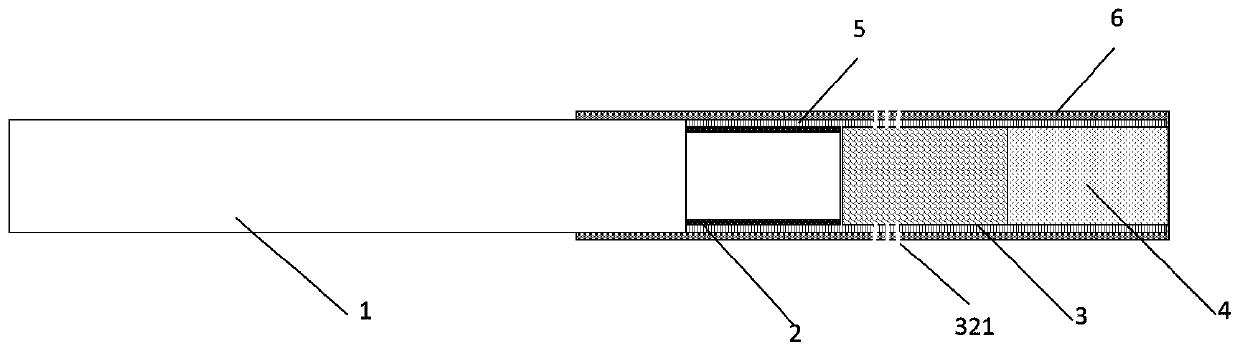

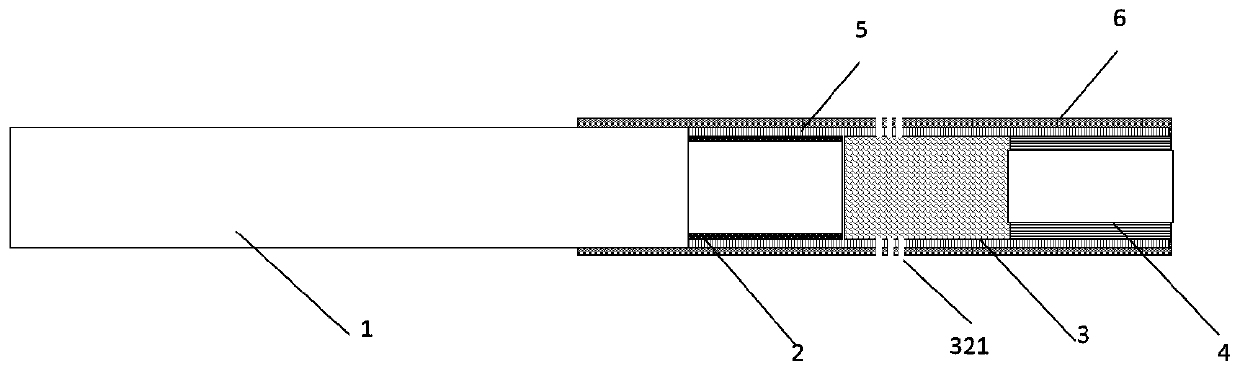

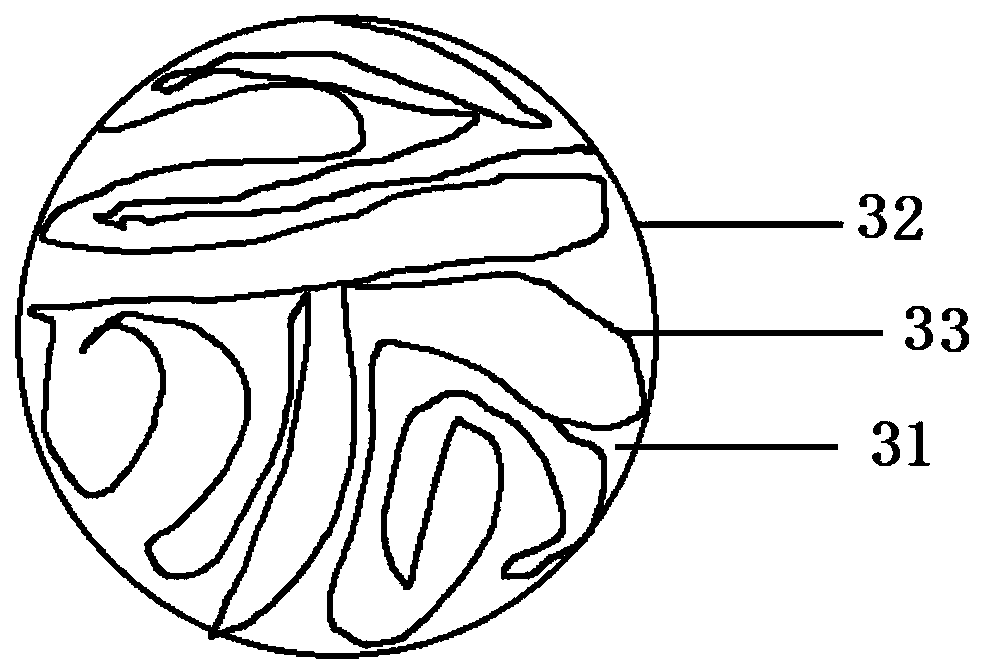

[0026] Such as figure 1 In this embodiment, the folded reconstituted tobacco leaf material is gathered disorderly as the reconstituted tobacco leaf cooling component. When the reconstituted tobacco leaf material is flattened, the width is 60mm, the thickness is 0.2mm, and the grammage is 120g / m 2 . The supporting unit 2, the reconstituted tobacco leaf cooling component 3 are connected with the filter unit 4 and wrapped with forming paper 5 to form a filter rod. The forming paper 5 is the tube wall 32 of the reconstituted tobacco leaf cooling unit. Then the cigarette core unit 1 and the filter rod were tipped through the tipping paper 6 to obtain a heat-not-burn cigarette sample A.

[0027] Correspondingly, heat-not-burn cigarette sample B was obtained by rolling the polylactic acid film cooling unit in the prior art. Heat-not-burn cigarette sample A and heat-not-burn cigarette sample B had the same cigarette structure, only the cooling unit was different.

[0028] Three expe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com