Anchor rod machining cold rolling machine with auxiliary feeding device

A technology for cold rolling mills and bolts, applied in feeding devices, threaded products, metal processing equipment, etc., can solve the problem of reducing the feeding speed and efficiency of operators, affecting the processing efficiency of equipment on steel, and lack of auxiliary feeding. installation and other problems, to achieve the effect of improving convenience and efficiency, improving convenience and labor saving, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

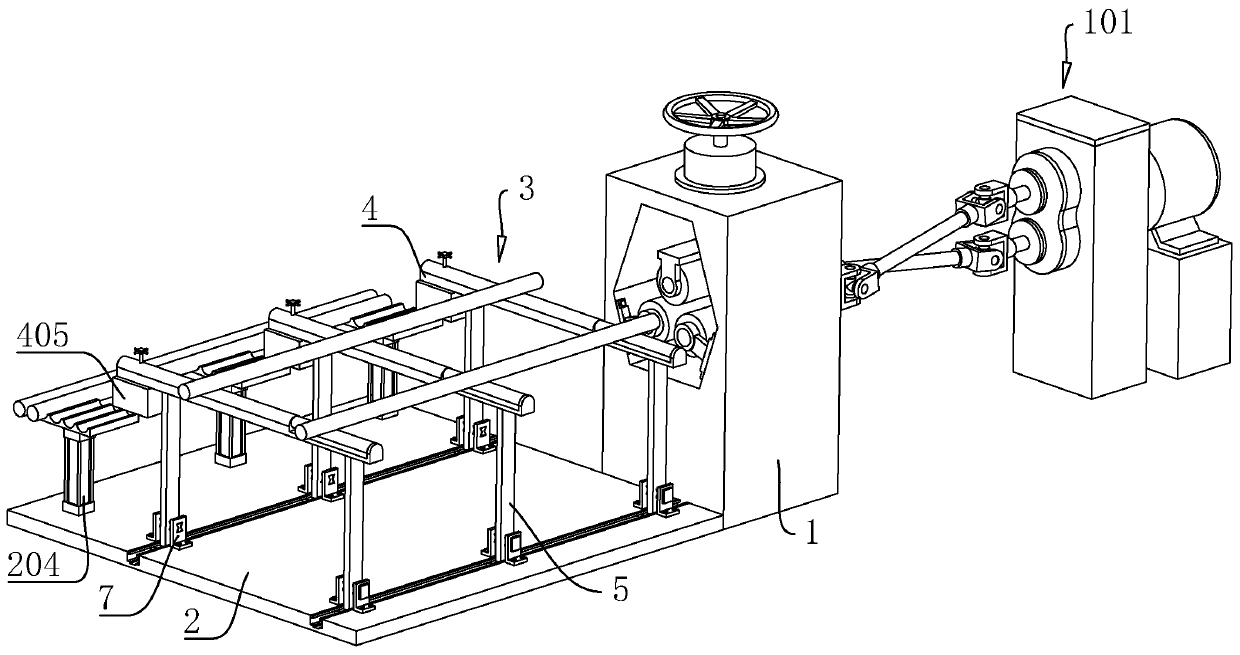

[0039] A kind of cold rolling mill for bolt processing with auxiliary feeding device, refer to figure 1 , including a machine head 1 and a driving device 101 located on one side of the machine head 1 in the width direction. The driving device 101 includes a motor and a reducer, and one end of the reducer close to the direction of the head 1 is connected with the head 1 through two cardan shafts.

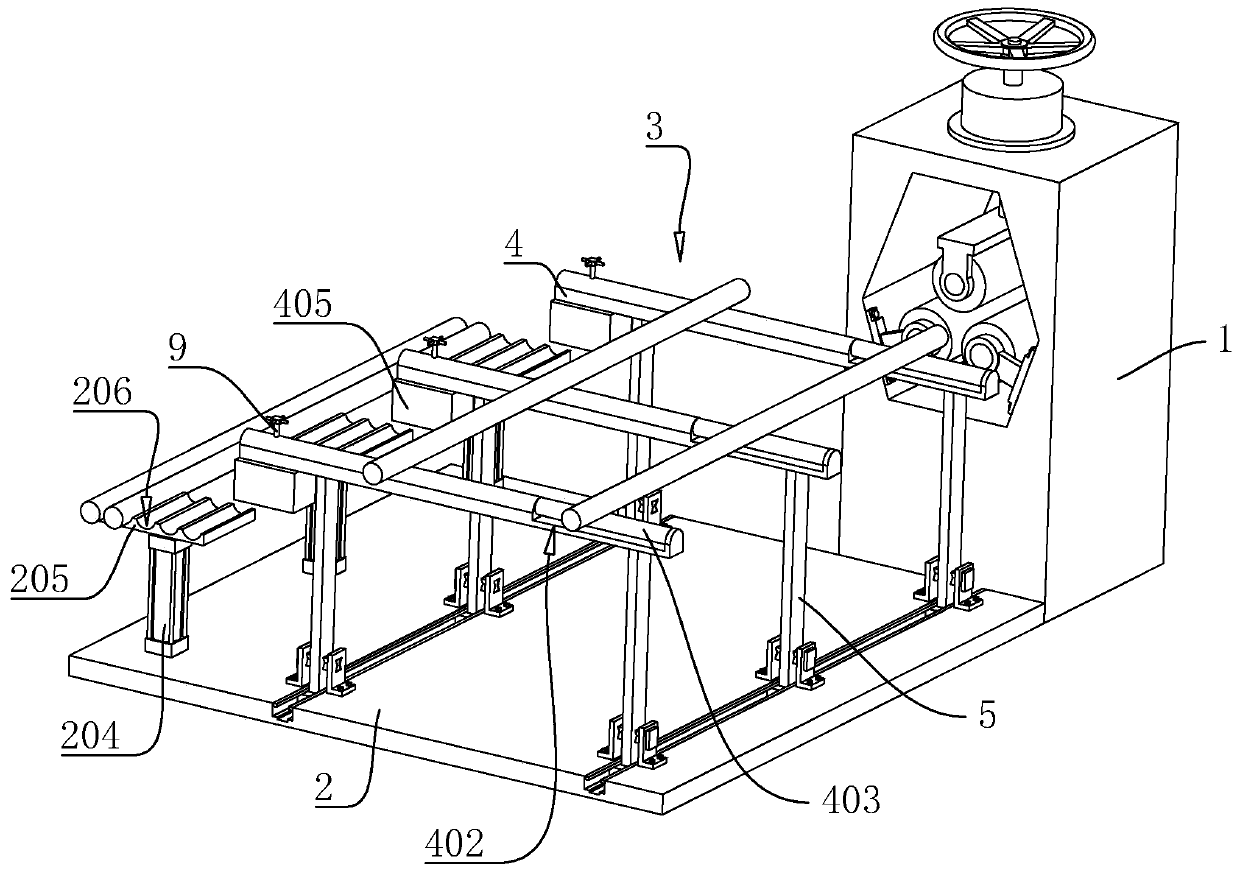

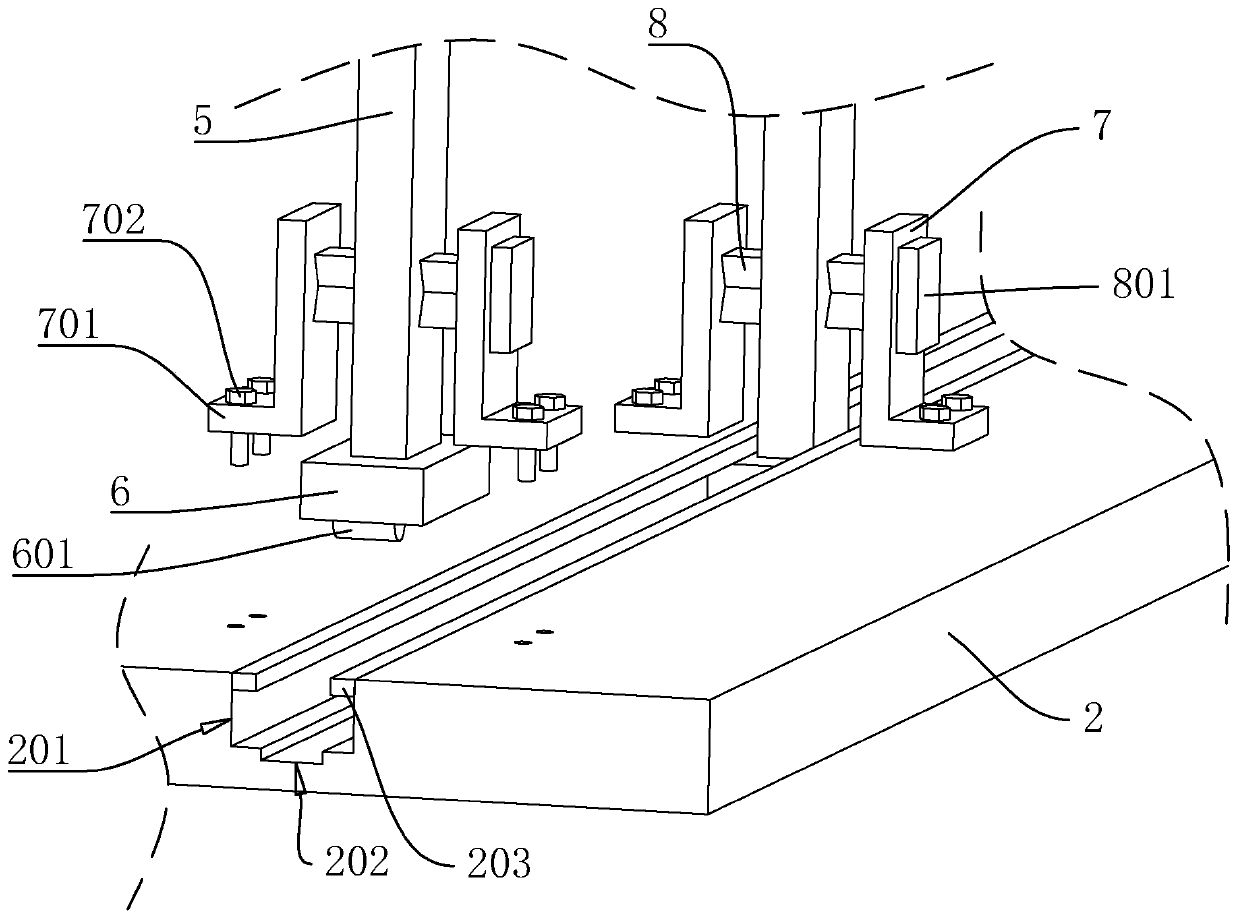

[0040] refer to figure 1 , figure 2 with image 3 The end of the machine head 1 away from the direction of the driving device 101 is provided with a support plate 2, the support plate 2 is a solid steel plate, which is fixed on the ground by bolts. There are several groups of receiving frames 3 arranged at intervals on the supporting plate 2 , and in this embodiment, there are three groups of receiving frames 3 . Each receiving frame 3 comprises a placement board 4, two bottom braces 5 and two stabilizing blocks 6, the placement board 4 is a horizontal plate body, its bottom wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com