A tundish flow stabilizer

A technology of flow stabilizer and tundish, which is used in casting melt containers, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven cleanliness and large internal quality gaps of casting billets, and achieves improvement of internal quality and cleanliness. degree, improve the effect of difficulty in opening and pouring while flowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

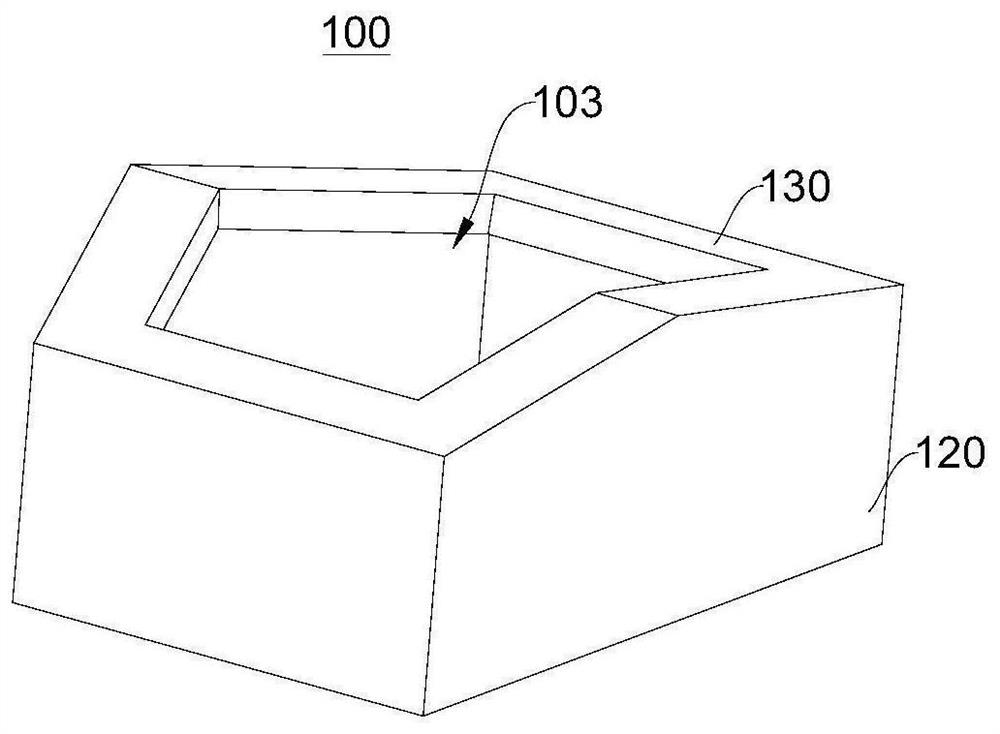

[0045] figure 1 A schematic structural view of the tundish current stabilizer 100 provided by the embodiment of the present application is shown; please refer to figure 1 , this embodiment provides a tundish flow stabilizer 100, which is mainly used for casting slabs.

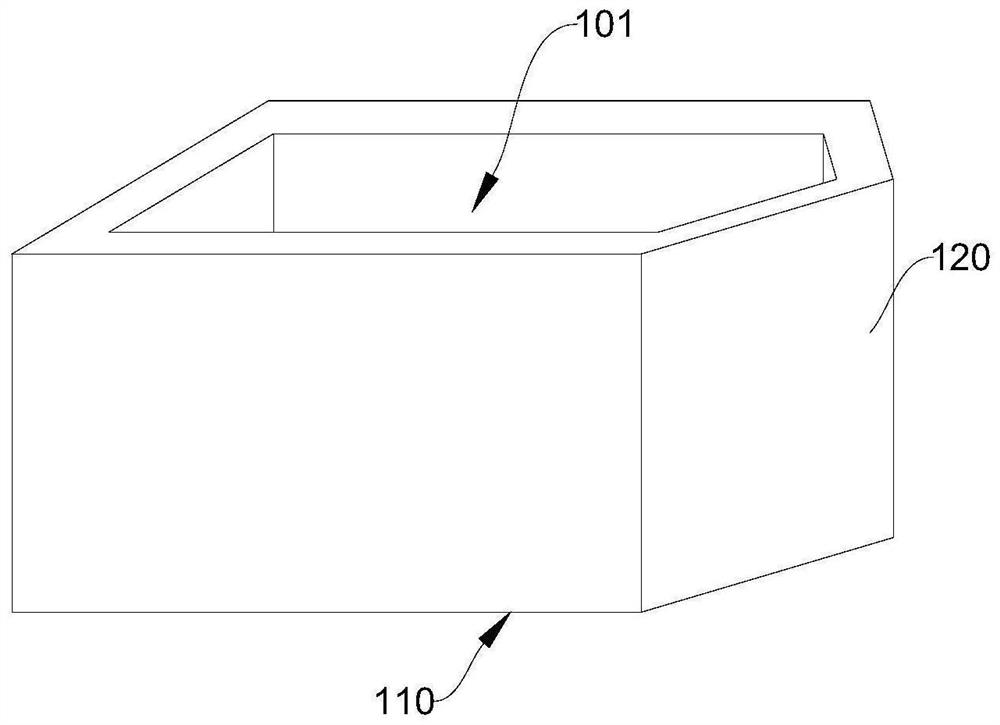

[0046] The tundish stabilizer 100 includes a base plate 110 (see figure 2 ), side plate 120 and roof eaves 130; side plate 120 has five, and five side plates 120 are all connected with base plate 110;

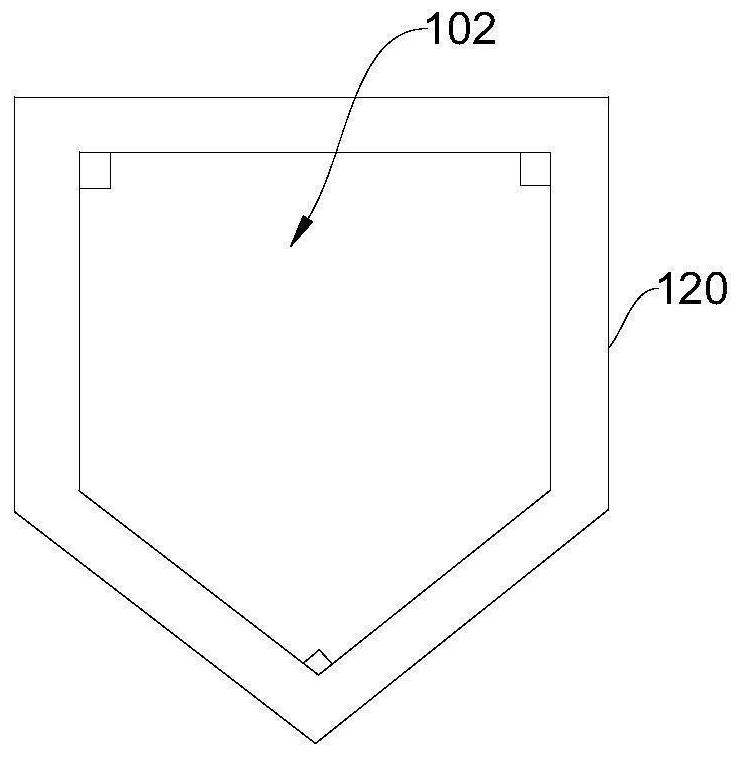

[0047] figure 2 It shows a schematic view of the structure of the bottom plate 110 and the side plate 120 provided by the embodiment of the present application at a first viewing angle, image 3 A schematic structural diagram of the second viewing angle of the bottom plate 110 and the side plate 120 provided by the embodiment of the present application is shown.

[0048] Please also refer to Figure 1-Figure 3 The tundish stabilizer 100 includes five side plates 120, and the five side plates 120 are all c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com