Production process of flower basket barrel

A production process and flower basket technology, which can be applied to devices and coatings that apply liquid to the surface, can solve problems such as reducing the sealing performance of flower basket barrels and prone to rust, and improve the quality of roll sealing, avoid rust, and increase structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be described in further detail below in conjunction with the accompanying drawings.

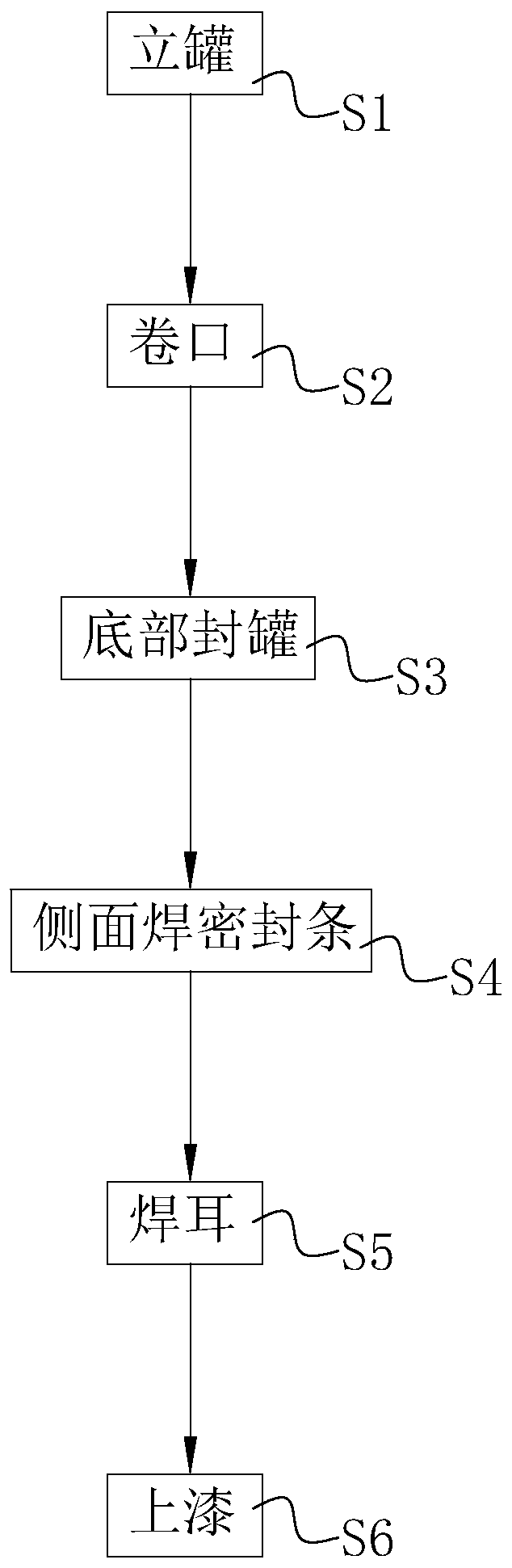

[0036] refer to figure 1 , a flower basket barrel production process disclosed by the invention, comprising the following steps,

[0037] S1: Vertical cans. The raw materials are seam welded to vertical cans, and after processing, the process of expanding cones and flanging is performed to obtain a barrel-shaped can body.

[0038] S2: Crimping, the can body is transported to the crimping machine for crimping, and after the crimping is completed, it is processed by the flower basket barrel expansion and flanging machine.

[0039] Among them, crimping includes pre-crimping and crimping, and pre-crimping is performed on the tank body first, and then crimping is performed. The crimped tank body can meet the quality inspection requirements, and the structural strength of the tank body itself is improved.

[0040] S3: Bottom sealing, after the processed tank is turned v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com