Auxiliary grinding system

A technology of auxiliary system and grinding device, applied in the direction of grinding machine parts, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of long training time, less operation than experienced users, and a lot of time to search. , to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

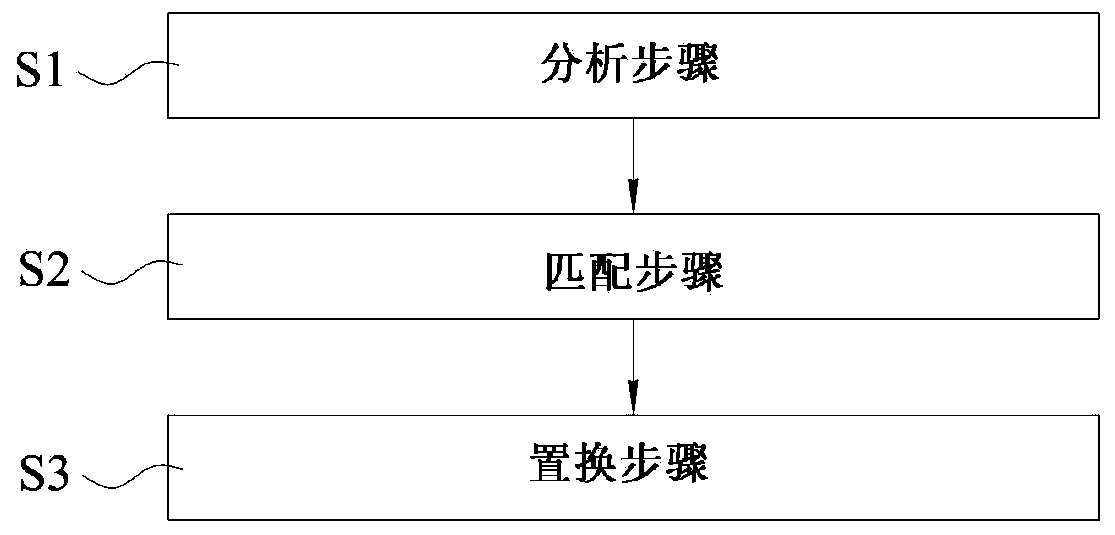

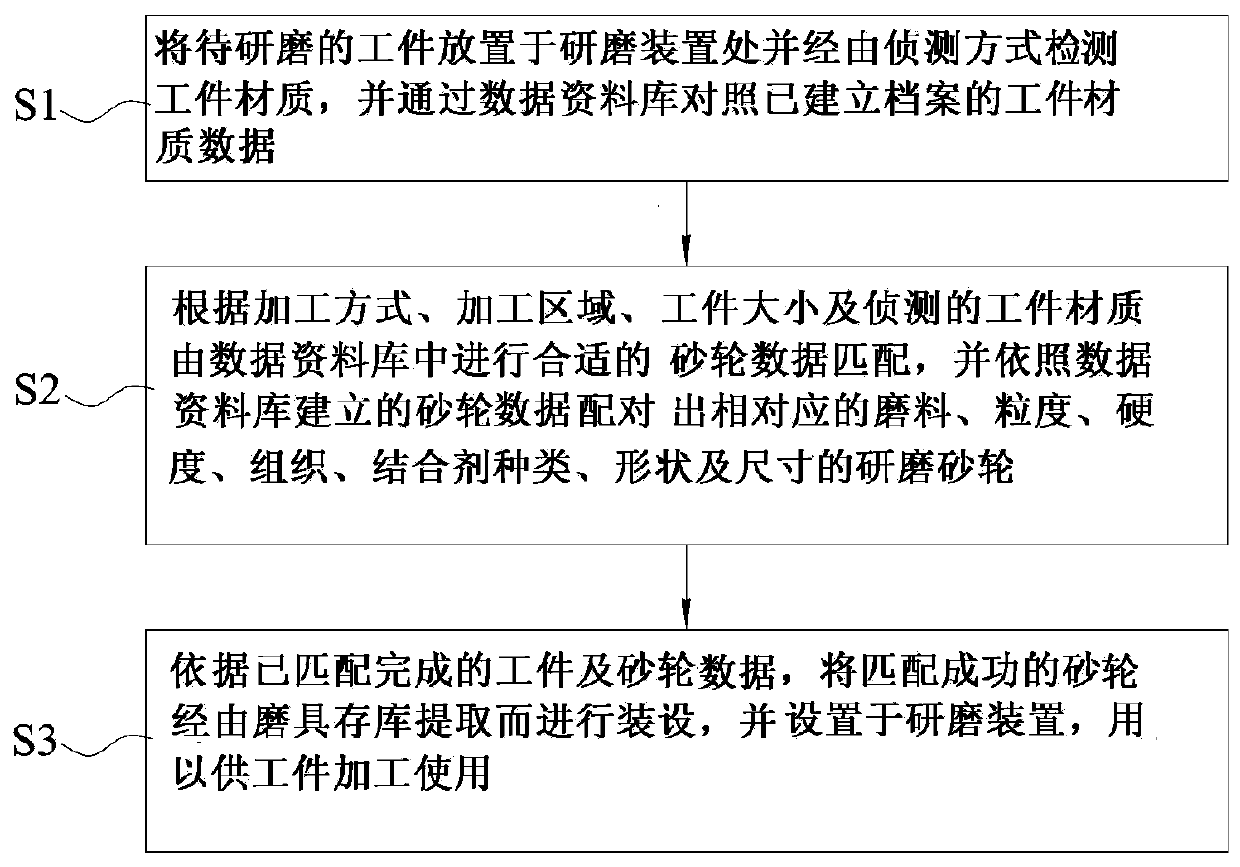

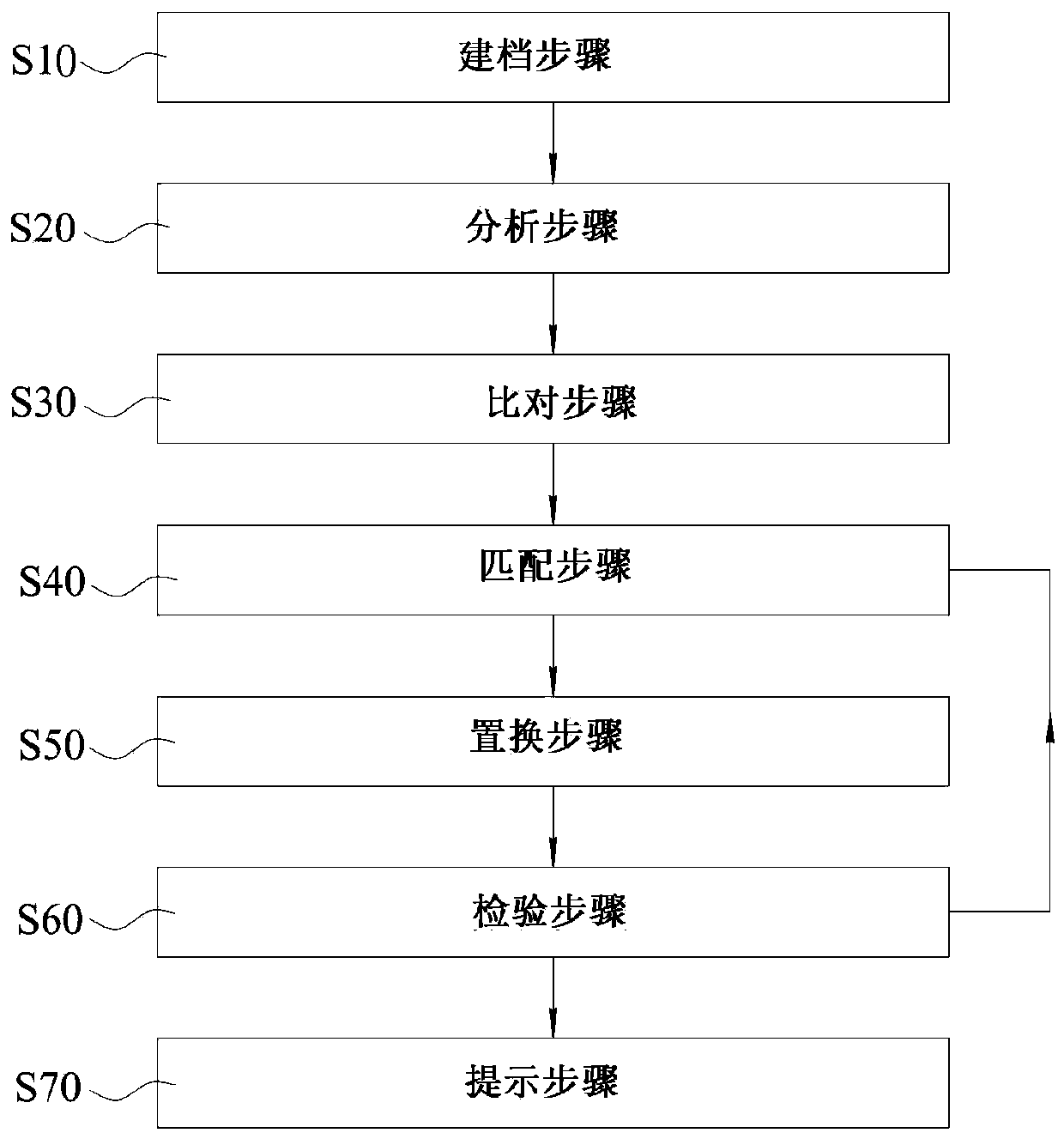

[0014] see Figure 1 to Figure 2 Shown, be grinding auxiliary system of the present invention, its system comprises the following steps:

[0015] Step S1: analysis step: place the workpiece to be ground on the grinding device and detect the material of the workpiece through the detection method, and compare the material data of the workpiece with the established file through the data database;

[0016] Step S2: Matching step: according to the speed, precision and roughness set by the user, fine-tune the processing parameters and match the detected workpiece material to match the appropriate grinding wheel data from the data database, and according to the grinding wheel data established in the data database Matching grinding wheels with corresponding abrasives, particle size, hardness, structure, binder type, shape and size for users to choose; and

[0017] Step S3: Replacement step: according to the matched workpiece and grinding wheel data, the matched grinding wheel is extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com