A tracked vehicle chassis for high-speed travel

A crawler and vehicle technology, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of insufficient vibration damping ability, etc., and achieve the effect of reducing driving burden, reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

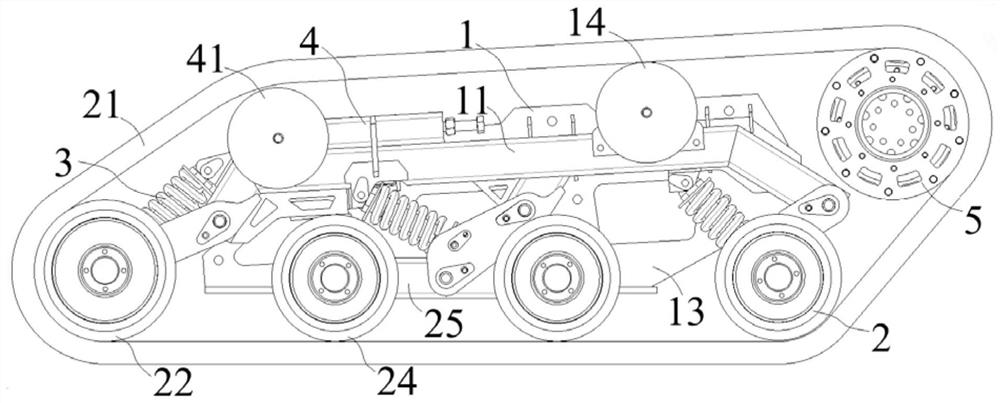

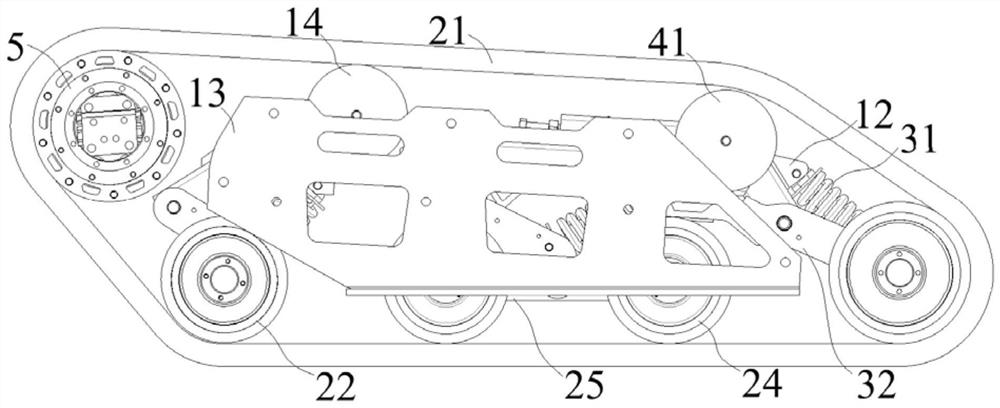

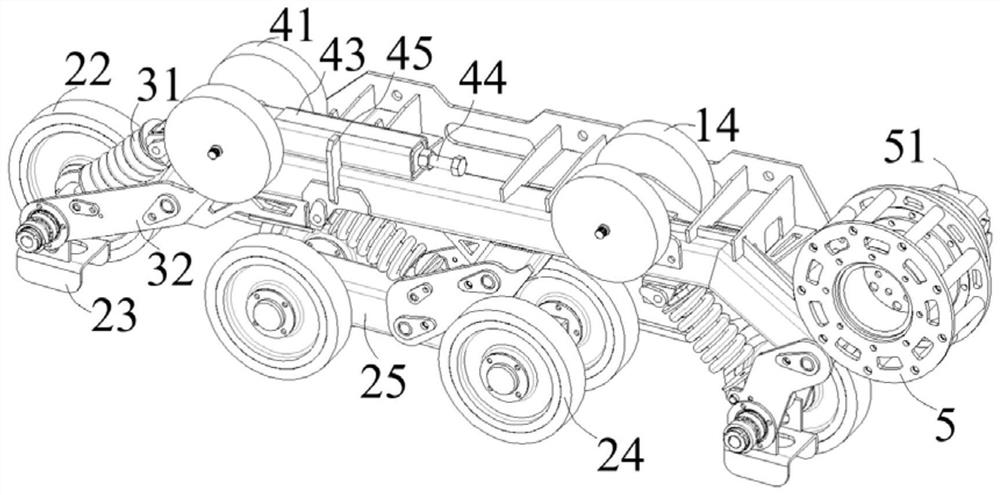

[0042] combine figure 1 and figure 2 , a tracked vehicle chassis for high-speed travel in this embodiment includes a support mechanism 1, a running mechanism 2, a damping mechanism 3, a tension mechanism 4 and a drive mechanism 5, and the support mechanism 1 includes a main beam 11 and connecting plate 13, the two form an integrated structure for supporting the vehicle, other mechanisms for fixing the vehicle chassis, the running mechanism 2 includes crawler belts 21 and a plurality of running wheels, the running wheels are connected to the supporting mechanism 1 through the damping mechanism 3, and the supporting The supporting wheel 14 of the mechanism 1, the running wheel of the traveling mechanism 2, the tensioning wheel 41 of the tensioning mechanism 4 and the driving wheel of the driving mechanism 5 jointly support the crawler belt 21, and travel under the driving of the driving mechanism 5.

[0043] The driving wheel in the present embodiment adopts shaft-shaped drivi...

Embodiment 2

[0051] combine Figure 5 and Figure 6 , the drive mechanism 5 of this embodiment is applied to a crawler vehicle chassis for high-speed travel described in Embodiment 1. In order to make it have a higher speed, a high-speed hydraulic motor is selected, but the hydraulic motor is not currently Applied to the drive of tracked vehicles without the motor output shaft commonly used in track drives. And the common driving wheel on the market is usually a toothed wheel, which is directly connected with the output shaft of the hydraulic motor to realize rotation. The high-speed hydraulic motor without output shaft used in this embodiment cannot find a suitable driving wheel on the market. In this embodiment, the driving mechanism 5 is comprehensively designed in combination with the characteristics of the high-speed motor and the toothed track.

[0052] The drive mechanism 5 includes a motor 51, a transition plate 52, an extension tube 53, a drive wheel plate 1 54, a drive wheel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com