Chain-jamming-preventing protection electric hoist capable of automatically oiling and lubricating

A technology of automatic refueling and electric hoist, which is applied in the direction of engine lubrication, engine components, spring mechanism, etc., can solve the problems of high lifting height, heavy objects, and workers' inability to provide assistance, so as to reduce the impact force, The effect of reducing the probability of chain knotting and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

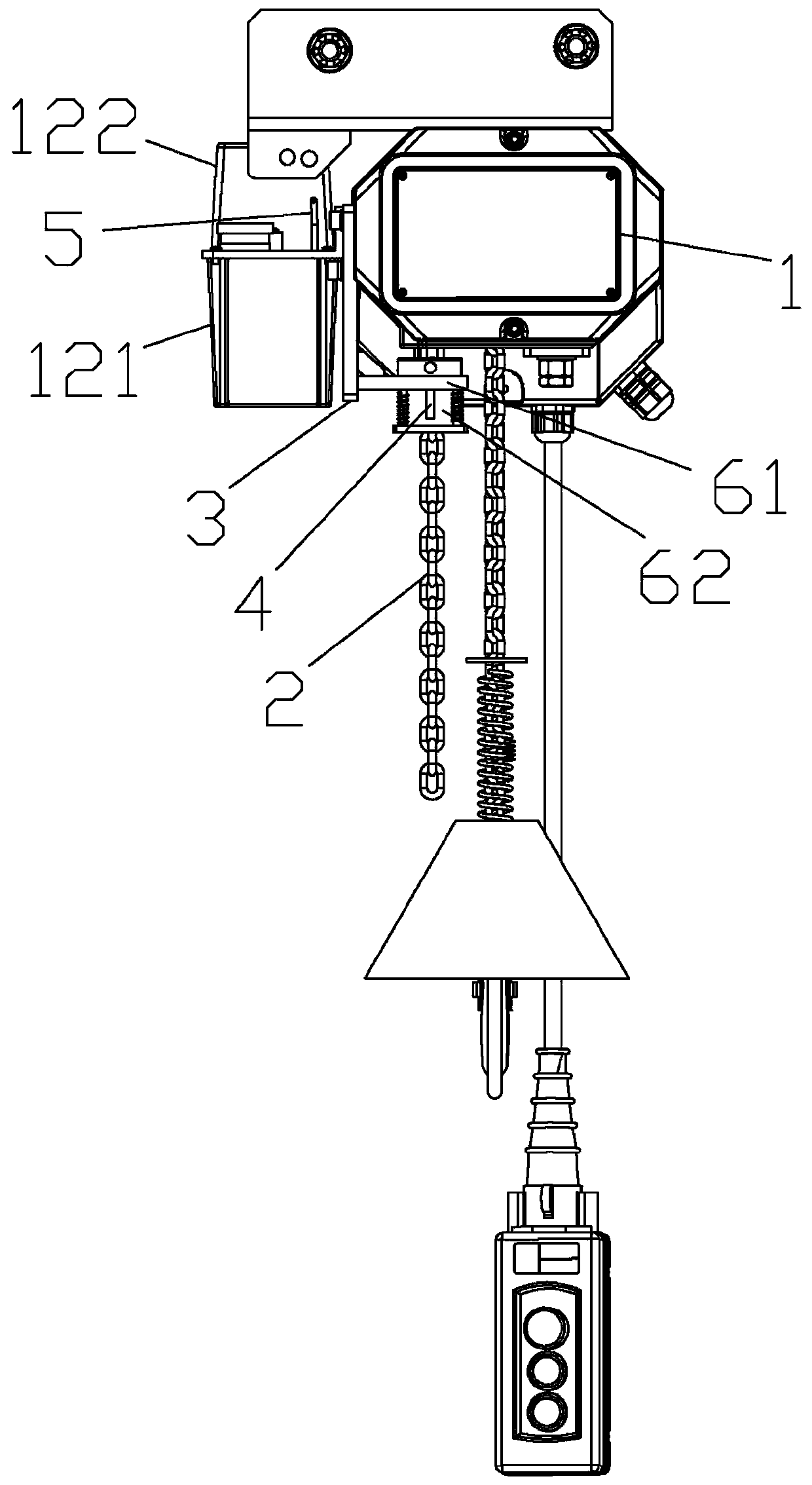

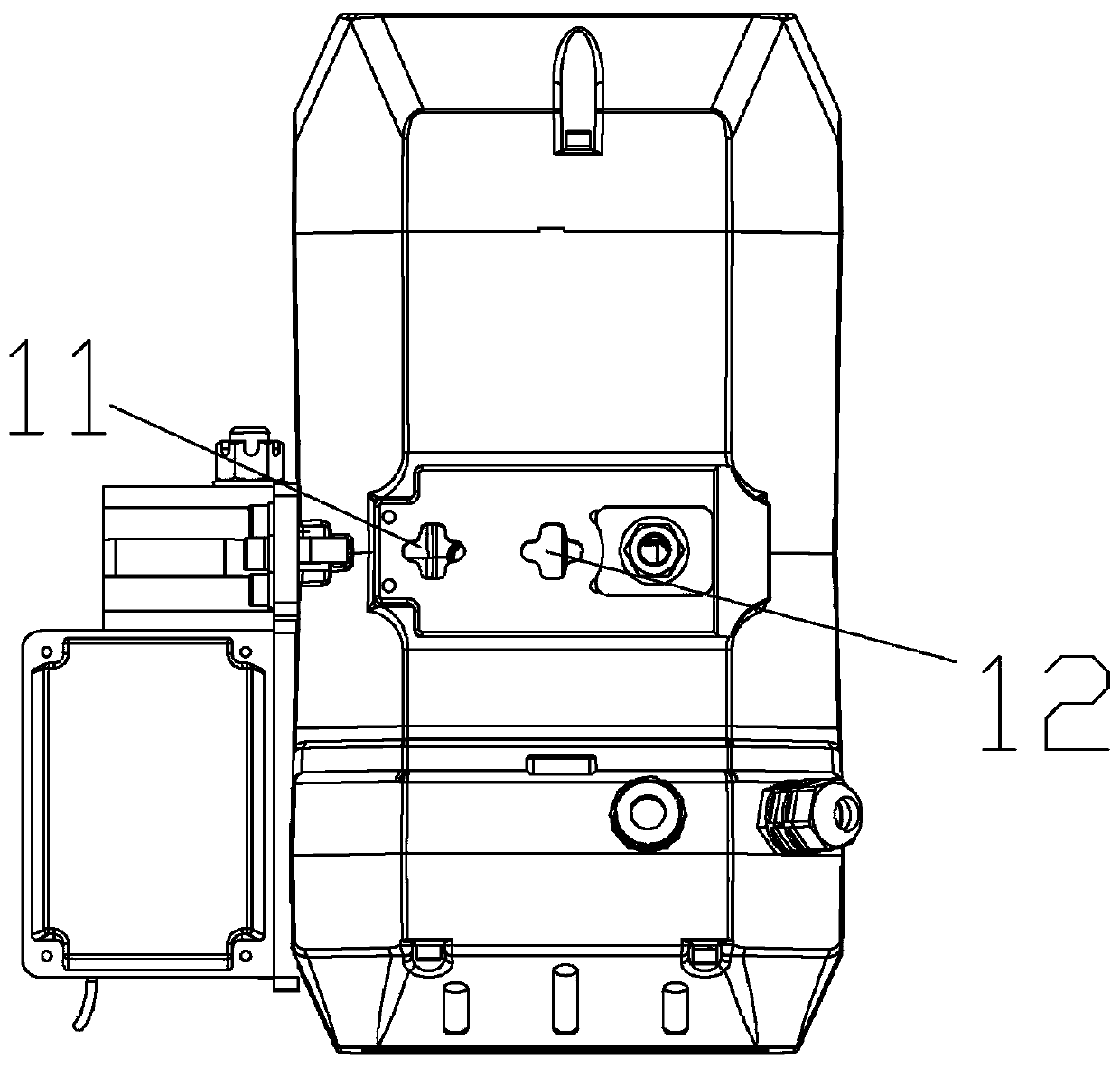

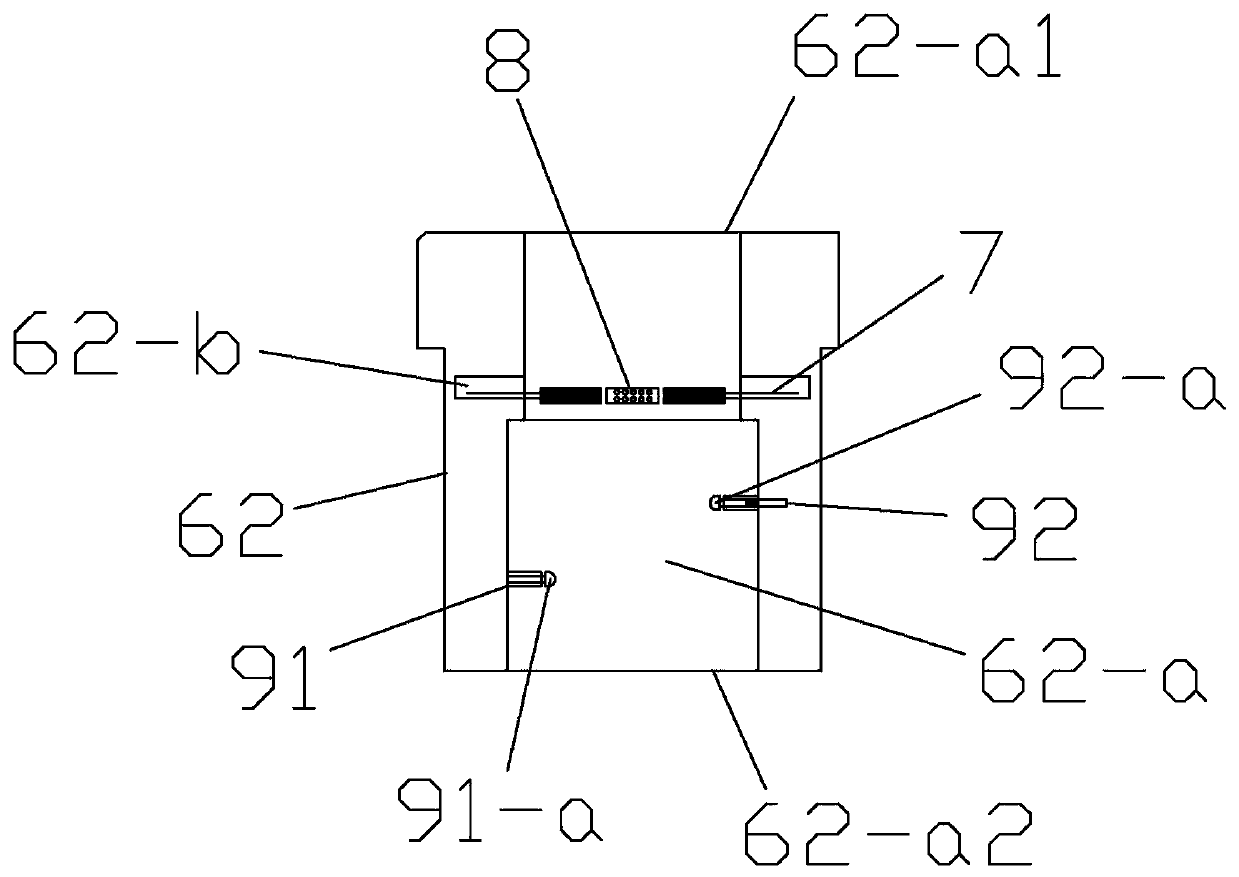

[0030] Refer to attached figure 1 , 2 : This self-lubricating anti-jamming chain protection electric hoist includes a casing 1 and a power source for driving the chain 2 in and out of the casing 1, and the chain 2 circulates in and out. Port 11 and chain outlet 12, the outer wall of one side of the casing 1 is equipped with a mounting plate 3, the mounting plate 3 has two connection ends, respectively connected with an anti-jamming protection device and a refueling device, the anti-jamming protection device is located in the casing 1, the chain 2 needs to pass through the anti-jamming protection device before entering the chain inlet 11. The anti-jamming protection device is provided with a limit switch 4, which is electrically connected to the power source and can stop the power when triggered. The power source is a three-phase asynchronous motor. The refueling device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com