Autoclaved aerated concrete slab and manufacturing process thereof

An aerated concrete slab and aerated concrete technology, which is applied in the field of building materials, can solve the problem that the bonding strength of the aerated concrete slab and the reinforced mesh sheet is not high, the comprehensive performance level of the aerated concrete slab is not high, and the mechanical properties of the concrete slab are reduced. and other problems, to achieve the effect of improving comprehensive mechanical properties, improving comprehensive mechanical properties, and reducing tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

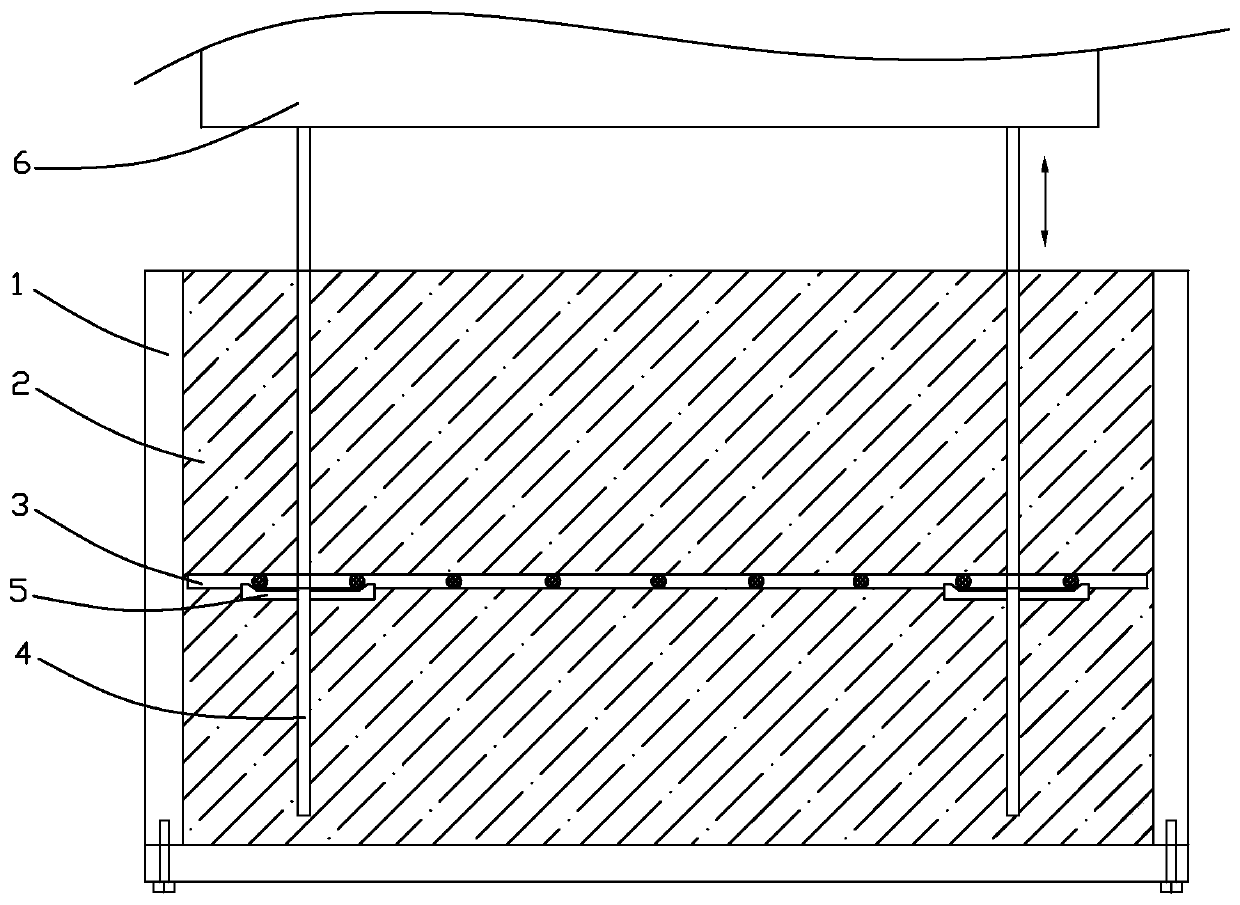

[0044] refer to figure 2 , is an autoclaved aerated concrete slab disclosed by the present invention, which is made of the following raw materials in parts by weight: 45 parts of quicklime, 42 parts of cement, 0.6 part of air-generating agent, 140 parts of mortar, 65 parts of waste slurry; the concrete slab is pre-embedded with reinforcement mesh 3 parallel to it.

[0045] Wherein, the length and width of the reinforced mesh sheet 3 and the aerated concrete slab are the same, and the thickness of the aerated concrete slab is 10-30 cm. The mortar is prepared by mixing and stirring the following raw materials in parts by weight: 10-12 parts of sand, 4-5 parts of gypsum, 9-11 parts of cement, 3-5 parts of fly ash, and 25-30 parts of water. The waste slurry is made by uniformly mixing the leftover material after the cutting process of the concrete slab and water, and the water accounts for 50-60% of the total mass of the mixture. The gas generating agent is selected from one or...

Embodiment 2

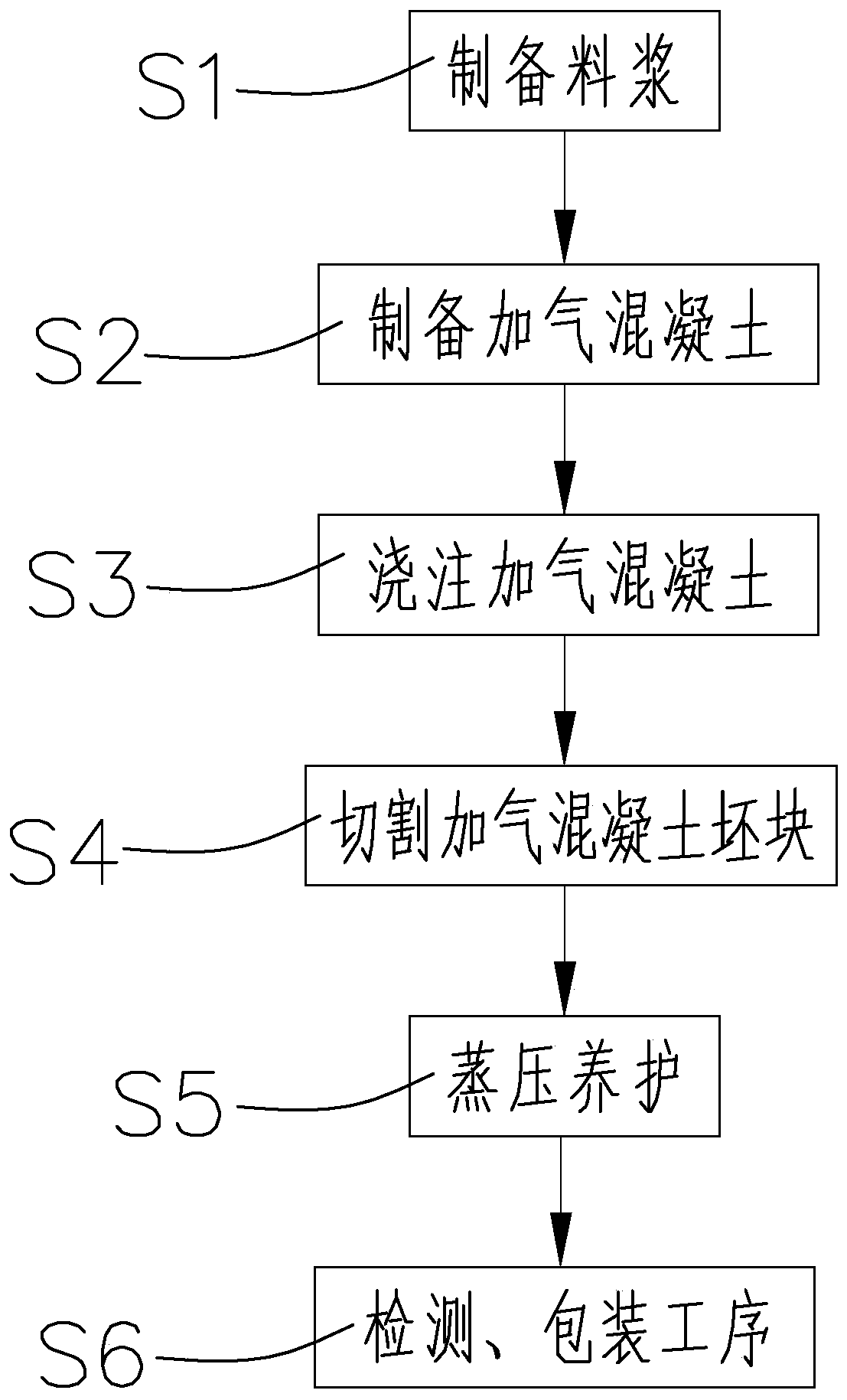

[0047] refer to figure 1 , 2 , is a kind of manufacturing process of the autoclaved aerated concrete slab disclosed by the present invention, carries out according to the following process steps:

[0048] S1. Preparation of slurry: All the raw materials for making the mortar are added to the slurry transition pit according to the above weight parts, and the agitator installed in the slurry transition pit is stirred at a speed of 350-400r / min, and it is prepared after stirring evenly The mortar is continuously stirred at a speed of 200-250r / min to maintain the fluidity of the mortar; the leftovers and water after the concrete slab cutting process are sent to the waste slurry transition pit, and the agitator installed in the waste slurry transition pit is 300-350r Stir at a speed of 180-230r / min to keep the fluidity of the waste slurry;

[0049] S2. Preparation of air-entrained concrete: Put the waste slurry, mortar, quicklime, cement, and air-generating agent prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com