Steel-concrete combined connection structure in concrete tension state

A combined connection and concrete technology, applied in construction, bridge construction, bridges, etc., can solve the problems of partial renovation of composite beams, complex on-site construction, high cost and uneconomical problems, and achieve superior interface shear bearing capacity, simple construction, The effect of increasing ductile energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

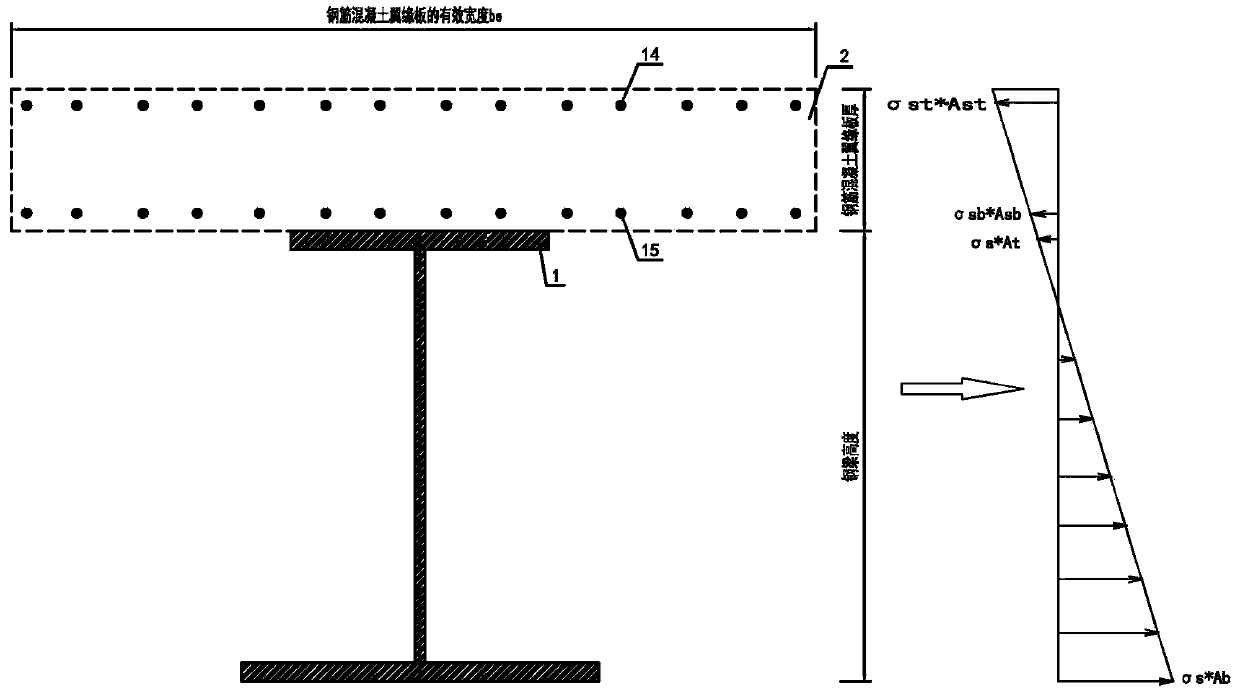

Embodiment 1

[0060] When the upper flange of the steel beam in the negative moment zone adopts the stud shear connector with constrained structure, when the concrete flange plate in the composite section is basically under the axial tension or the tension-bend composite tension state, the concrete is always under the full-section tension state, according to the single stud 3 shear triangular truss balance unit, it can be known that when the whole concrete is in a tension state, it is impossible to form an oblique concrete compression bar in the concrete flange plate like the concrete in the compression zone, and the stud 3 The shear resistance requires the oblique component force of the longitudinal and transverse steel bars at the top and bottom of the flange plate to provide the slash tension in the shear triangle truss balance unit of the stud 3 to balance the longitudinal shear force of the stud 3. Therefore, in order to balance the restraint For the longitudinal shear force of the cons...

Embodiment 2

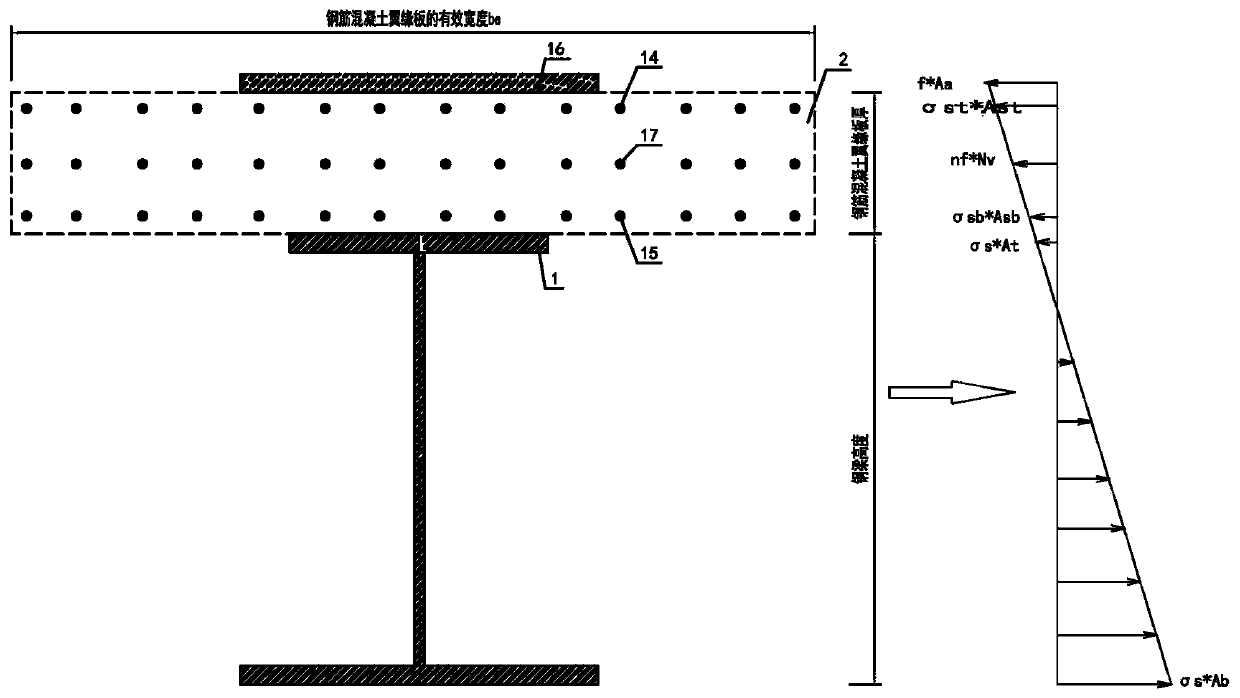

[0064] A steel plate for resisting tensile stress to compensate for strength and stiffness is directly added at the maximum tensile stress of the concrete flange plate section, that is, a tensile steel plate 16 is added on the top of the steel beam concrete flange plate 2, and the additional tensile steel plate at this position directly Bear the section tensile stress of the concrete flange plate at this position. In the negative moment zone of the continuous composite beam, the steel-concrete composite slab is formed by the shear connector 3 with restraint structure and the additional steel plate on the top of the concrete flange plate 2 of the steel beam. The shear force transmission capacity of the constructed stud 3 shear connectors is realized. Due to the use of the stud 3 shear connector with constrained structure, the shear connector can effectively avoid local pressure splitting damage, has strong shear stiffness, and still has a good shear force when the shear force e...

Embodiment 3

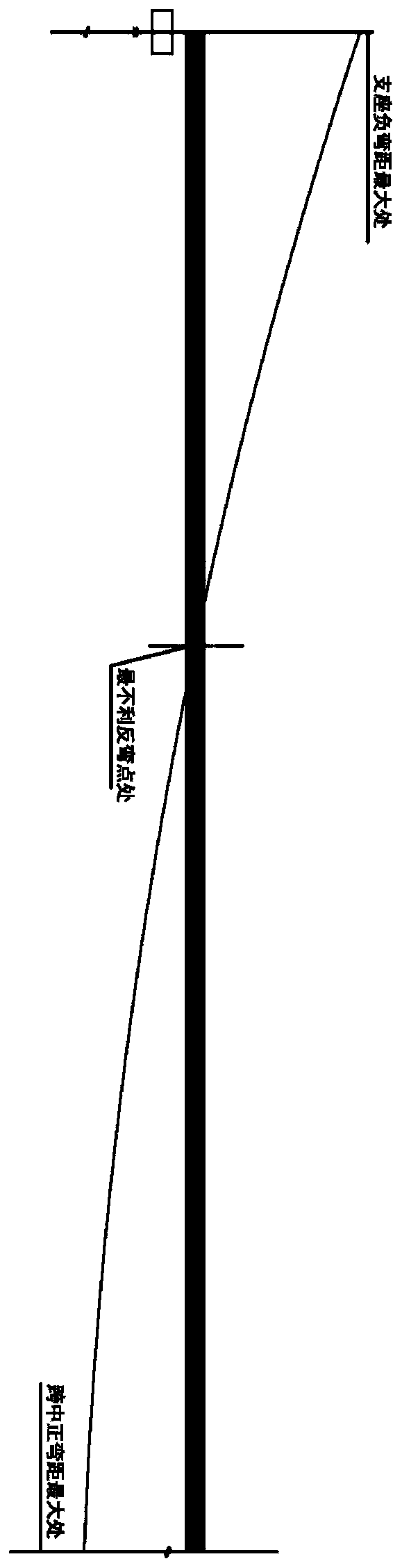

[0067] In the first and second embodiments above, the two connection methods are adopted simultaneously, that is, an additional oblique reinforcement 17 and an additional transverse reinforcement 18 to resist the shear force of the stud 3 are added at the neutral axis section of the concrete flange plate section, When the concrete is in tension as a whole, the balance tie element of a single stud 3 shear triangular truss balance element (such as Figure 19 Shown) and the composite beam concrete flange plate 2 top additional tensile steel plate 16 of the composite beam concrete flange plate 2 top that directly increases the compensating composite beam strength resisting tensile stress at the maximum tensile stress of the concrete flange plate section, the typical continuous of its present invention proposes The schematic diagram of the mechanical characteristics of the composite section in the negative moment zone of the composite beam is as follows: figure 2 shown.

[0068] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com