Method for embedding optical fiber for testing internal force of cast-in-place pile by acoustic testing pipe

A technology of acoustic measuring tube and cast-in-place pile, which is applied to the test of sheet pile wall, foundation structure, construction, etc., and can solve the problems of increasing the interval time of pouring concrete and increasing the collapse of pile holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

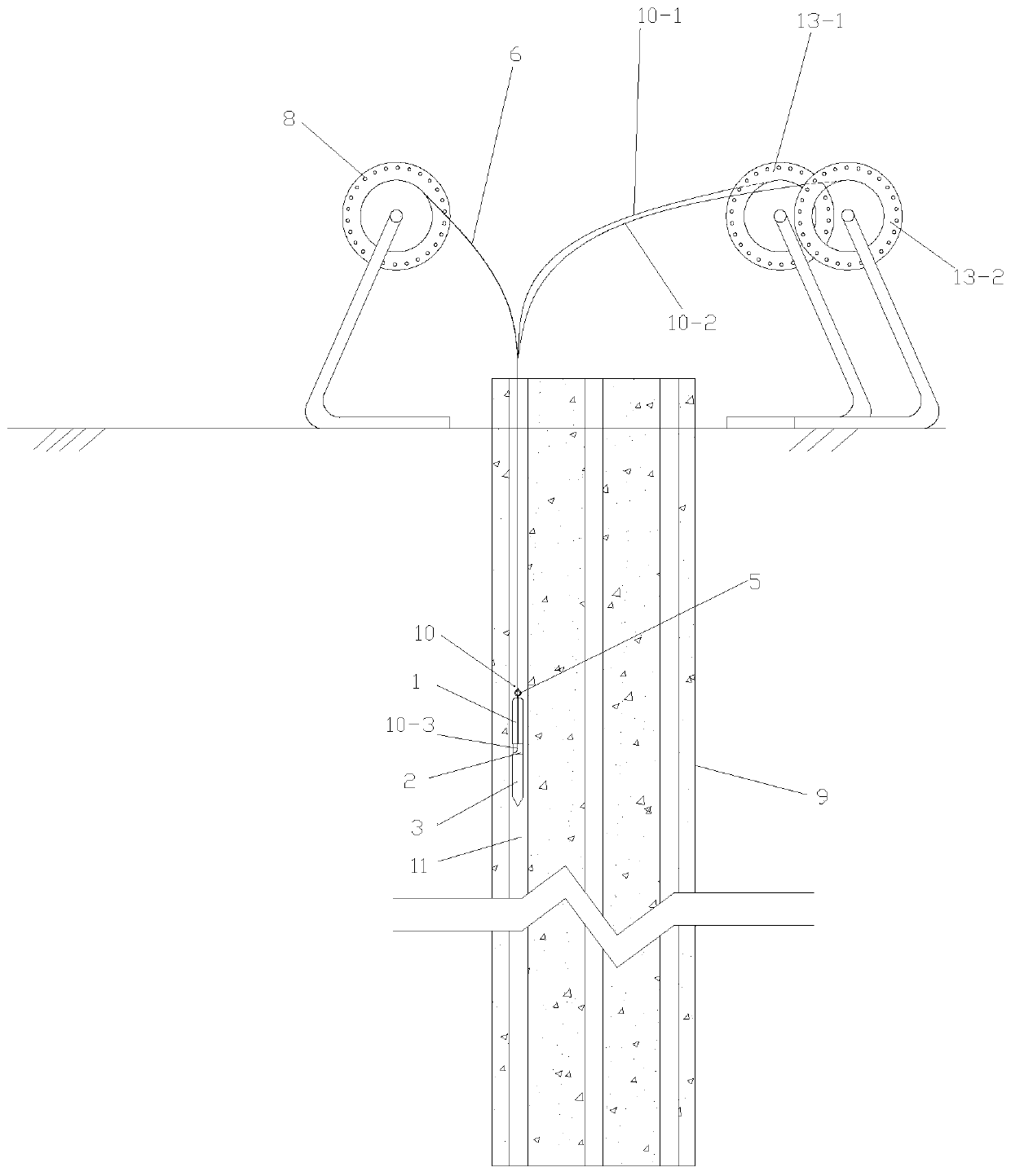

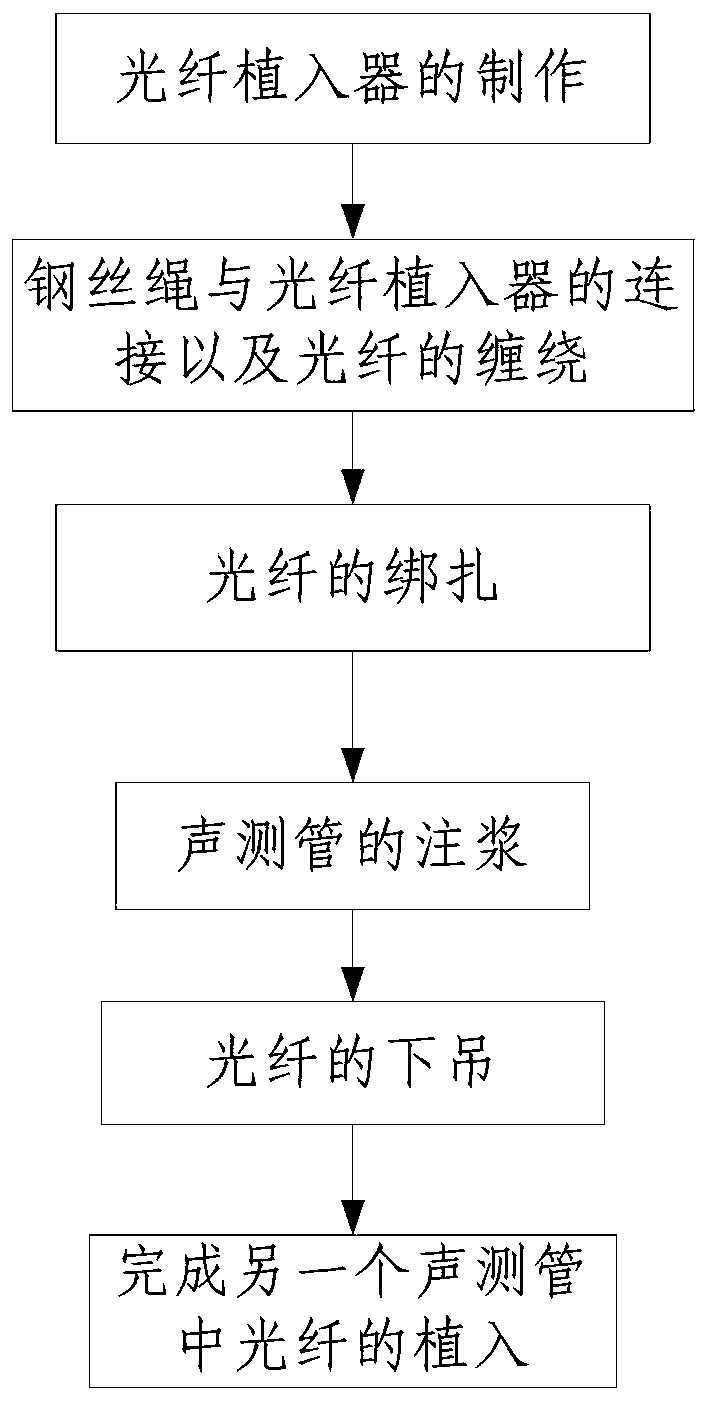

[0067] Such as Figure 1 to Figure 3 A method for implanting an optical fiber for testing the internal force of a cast-in-situ pile by using an acoustic measuring tube includes the following steps:

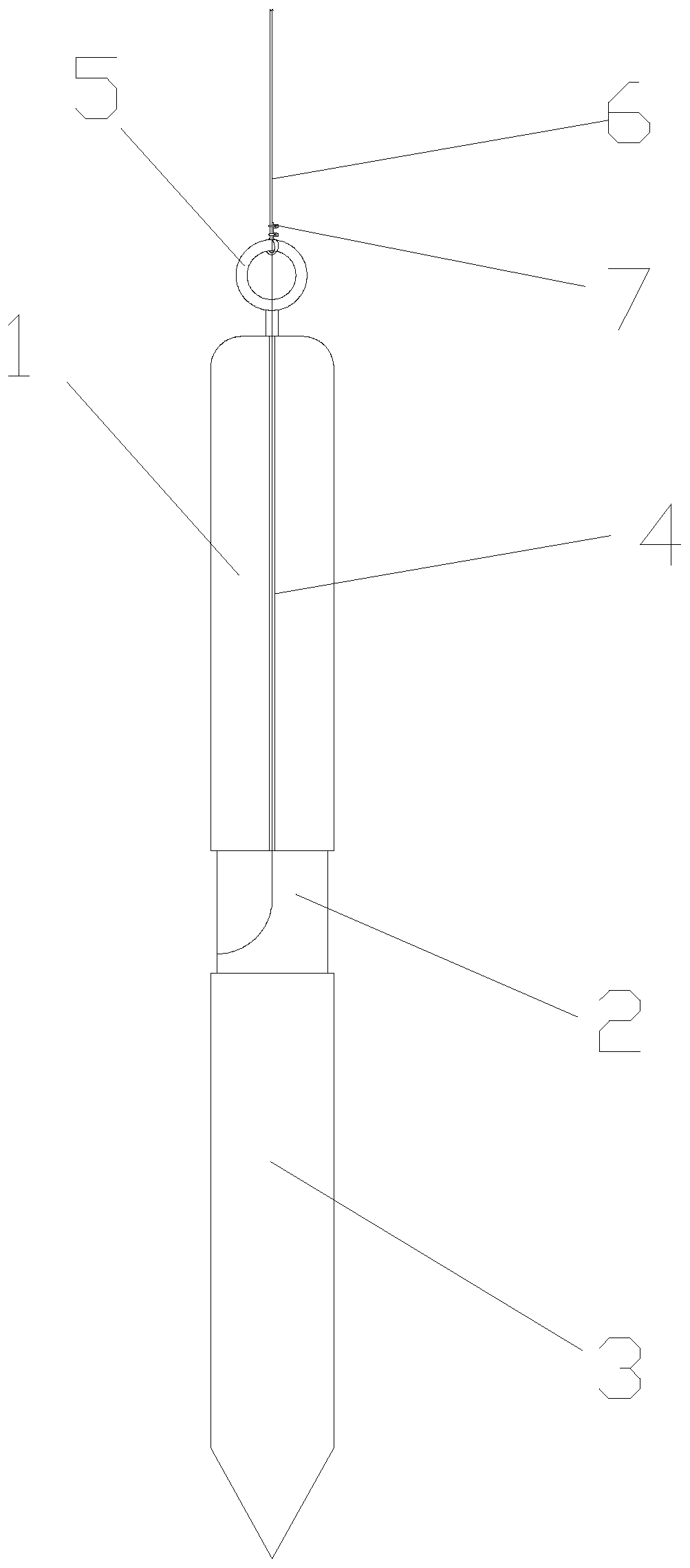

[0068] Step 1. Production of optical fiber implanter:

[0069] Step 101, connect the fiber guide rod 1, the fiber optic swivel section 2 and the bottom hammer head 3 sequentially from top to bottom; wherein, the diameter of the fiber swivel section 2 is smaller than the diameter of the fiber guide rod 1, and the fiber guide rod 1, fiber swivel section 2 and the bottom hammer head 3 are integrally formed;

[0070] Step 102, setting two symmetrically arranged guide grooves 4 on the optical fiber guide rod 1 to obtain an optical fiber implanter;

[0071] Step 2, the connection of the wire rope and the optical fiber implanter and the winding of the optical fiber:

[0072] Step 201, install the suspension ring 5 on the upper end of the fiber guide rod 1;

[0073] Step 202, install ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com