Underground excavation station arch bridge type arc-shaped middle plate construction method

A construction method and arc-shaped technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of cumbersome construction, reduced space utilization, and long construction period, so as to reduce the difficulty of construction organization and make efficient organization arrangements , Improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

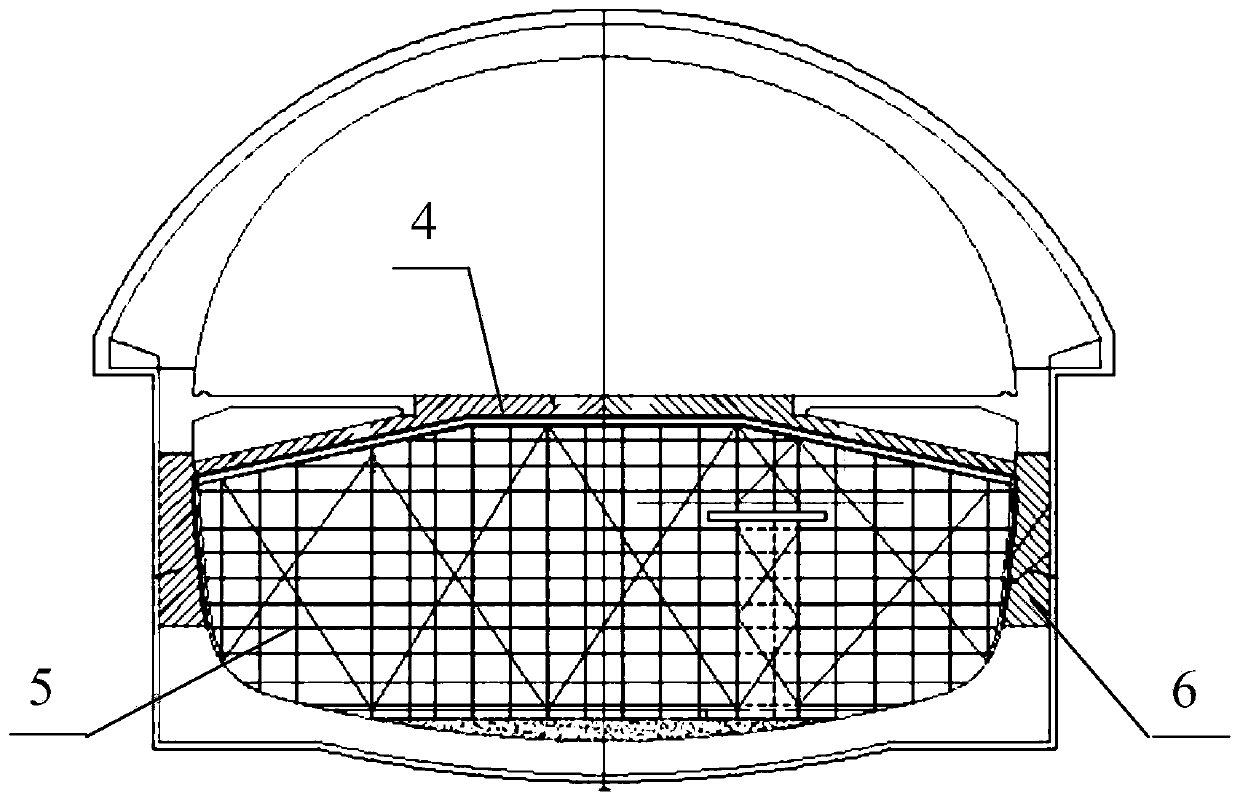

[0040] According to one embodiment of the present invention, the step S5) includes pouring in the formwork of the arc-shaped middle plate 4 to form the arc-shaped middle plate 4, including: The two ends of the formwork 4 with the lowest elevation are poured symmetrically toward the middle to form the arc-shaped middle plate 4 . Preferably, concrete tank trucks and ground pumps are used for pouring. During the pouring process, the rise of the pouring should be observed at any time, and the pouring speed should be controlled according to the actual situation; the plug-in vibrator is used for vibrating operations to ensure the appearance quality of the pouring.

[0041] According to the technical solution of the present invention, step S6) on the top surface of the formed arc-shaped middle plate 4 and the top surface of the remaining side wall 6, build the flat surface of the rail top air duct part of the arc-shaped middle plate 4 The formwork of the straight section axillary ang...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap