Automatic ramming recording system for height measurement of dynamic compactor

A height measurement and recording system technology, applied in the direction of measuring devices, general control systems, control/regulation systems, etc., can solve problems such as insufficient monitoring and supervision, no scientific record keeping of construction engineering records, and inability to ensure consistent lifting height of rammers, etc. , to achieve stable and reliable construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

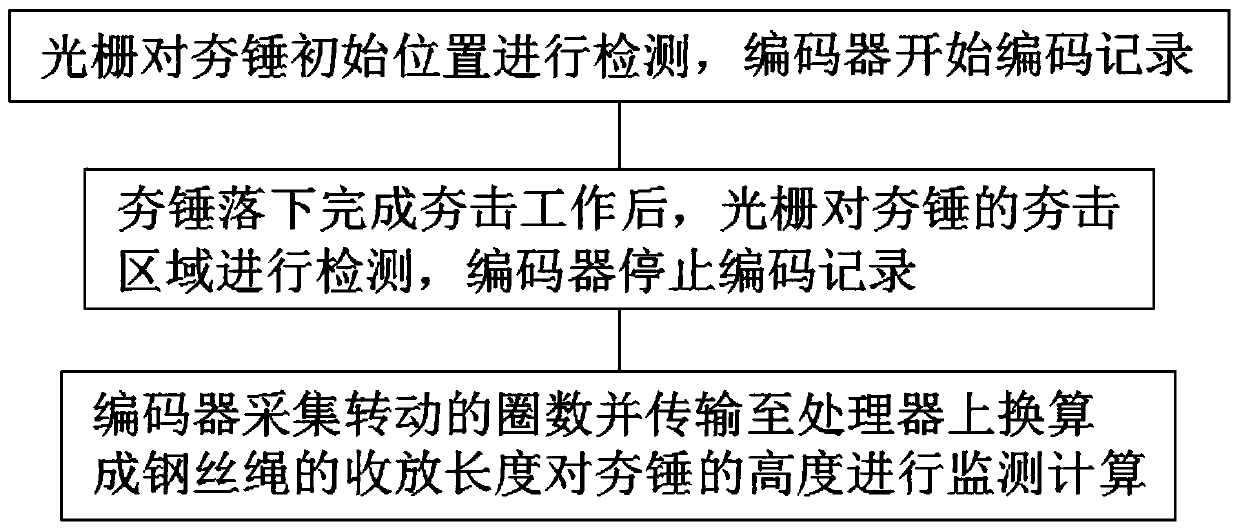

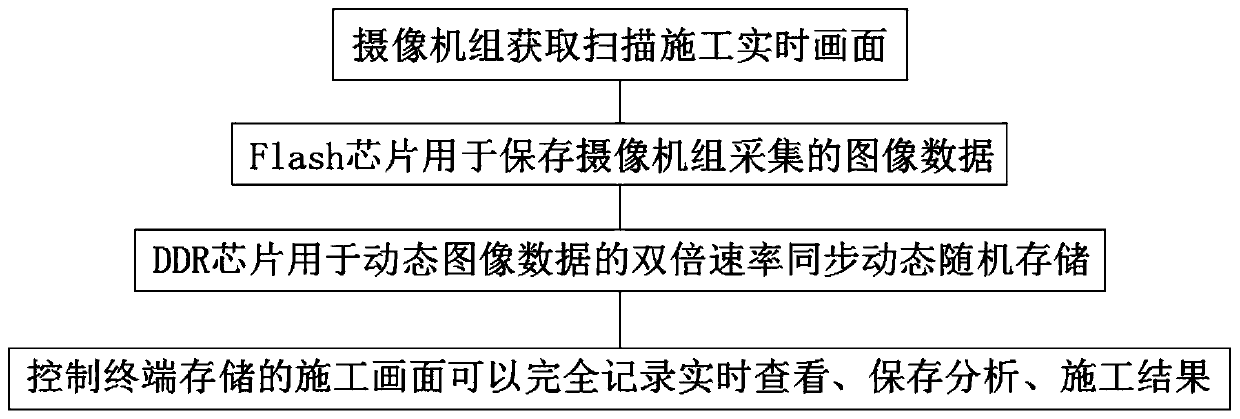

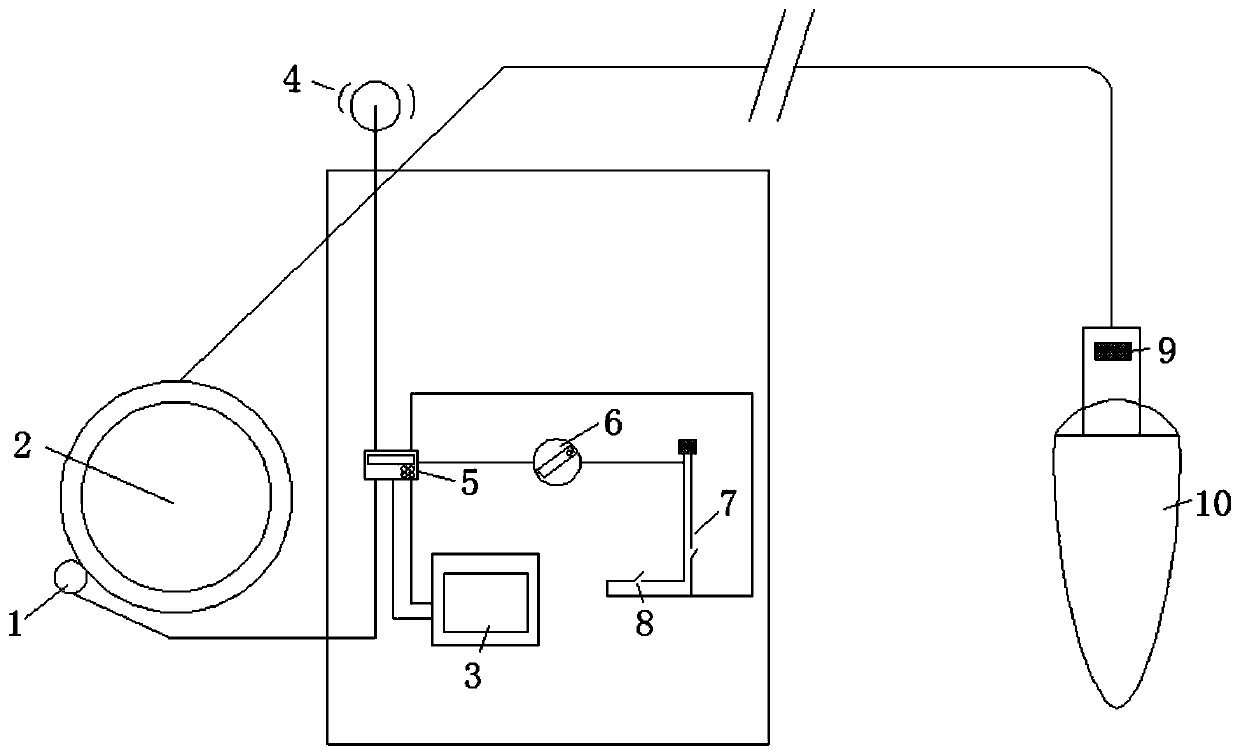

[0020] An automatic tamping recording system for height measurement of a dynamic tamping machine, comprising a dynamic tamping machine equipped with a processor, a hoist for the dynamic tamping machine, a tamper for the dynamic tamping machine, an encoder installed on the hoist, A camera group for infrared monitoring and supervision of safe construction and for remote recording operations, the said dynamic tamping machine equipped with a processor is provided with a relay connected to the single-chip microcomputer, and the said rammer is equipped with a remote control circuit for controlling the relay, The remote control circuit receives execution instructions from the processor, and the relay controls the rammer to work. The display control device on the processor is preset with an encoder display, reset to zero, emergency switch, automatic manual switch and manual release switch , the display control device on the control terminal is preset with a level-1 height alarm, a leve...

Embodiment 2

[0026] An automatic tamping recording system for height measurement of a dynamic tamping machine, comprising a dynamic tamping machine equipped with a processor, a hoist for the dynamic tamping machine, a tamper for the dynamic tamping machine, an encoder installed on the hoist, A camera group for infrared monitoring and supervision of safe construction and for remote recording operations, the said dynamic tamping machine equipped with a processor is provided with a relay connected to the single-chip microcomputer, and the said rammer is equipped with a remote control circuit for controlling the relay, The remote control circuit receives execution instructions from the processor, and the relay controls the rammer to work. The display control device on the processor is preset with an encoder display, reset to zero, emergency switch, automatic manual switch and manual release switch , the display control device on the control terminal is preset with a level-1 height alarm, a leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com