Logistics equipment fault prediction terminal based on edge computing

A fault prediction and edge computing technology, applied in computing, computer control, measurement devices, etc., can solve the problems of untimely data processing, consuming large network bandwidth, and consuming more resources, so as to reduce the risk of privacy leakage and reduce data The effect of transmission bandwidth and simple circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific embodiments. It should be understood by those skilled in the art that the specific implementations are only to help understand the present invention and should not be regarded as specific limitations to the present invention.

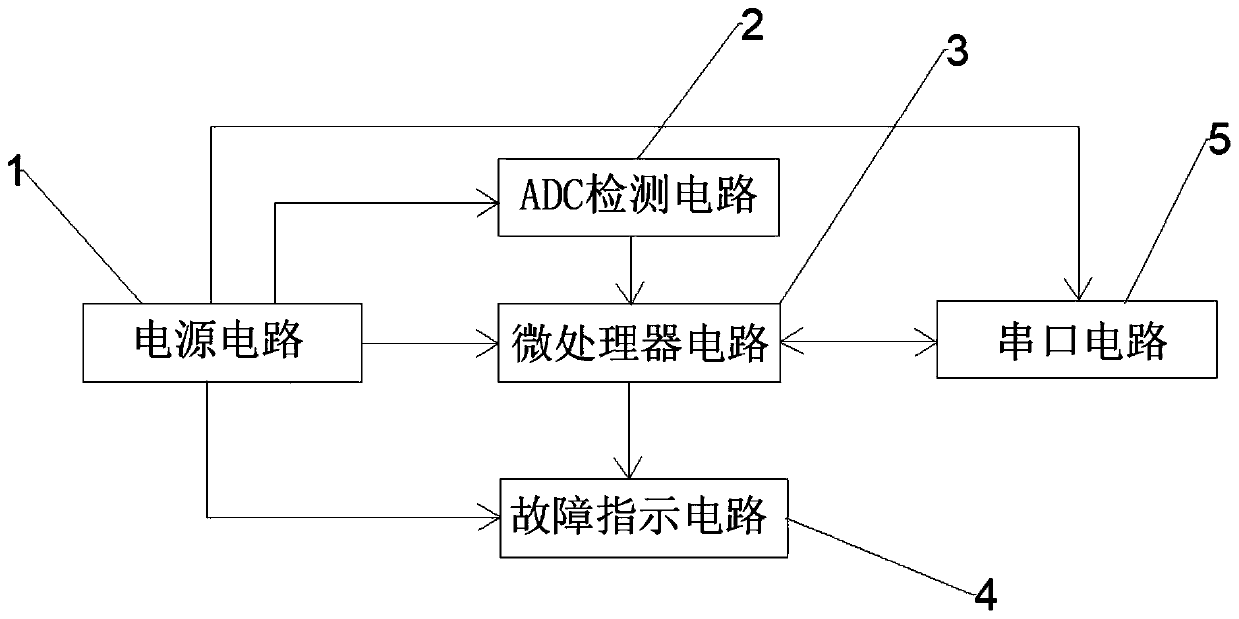

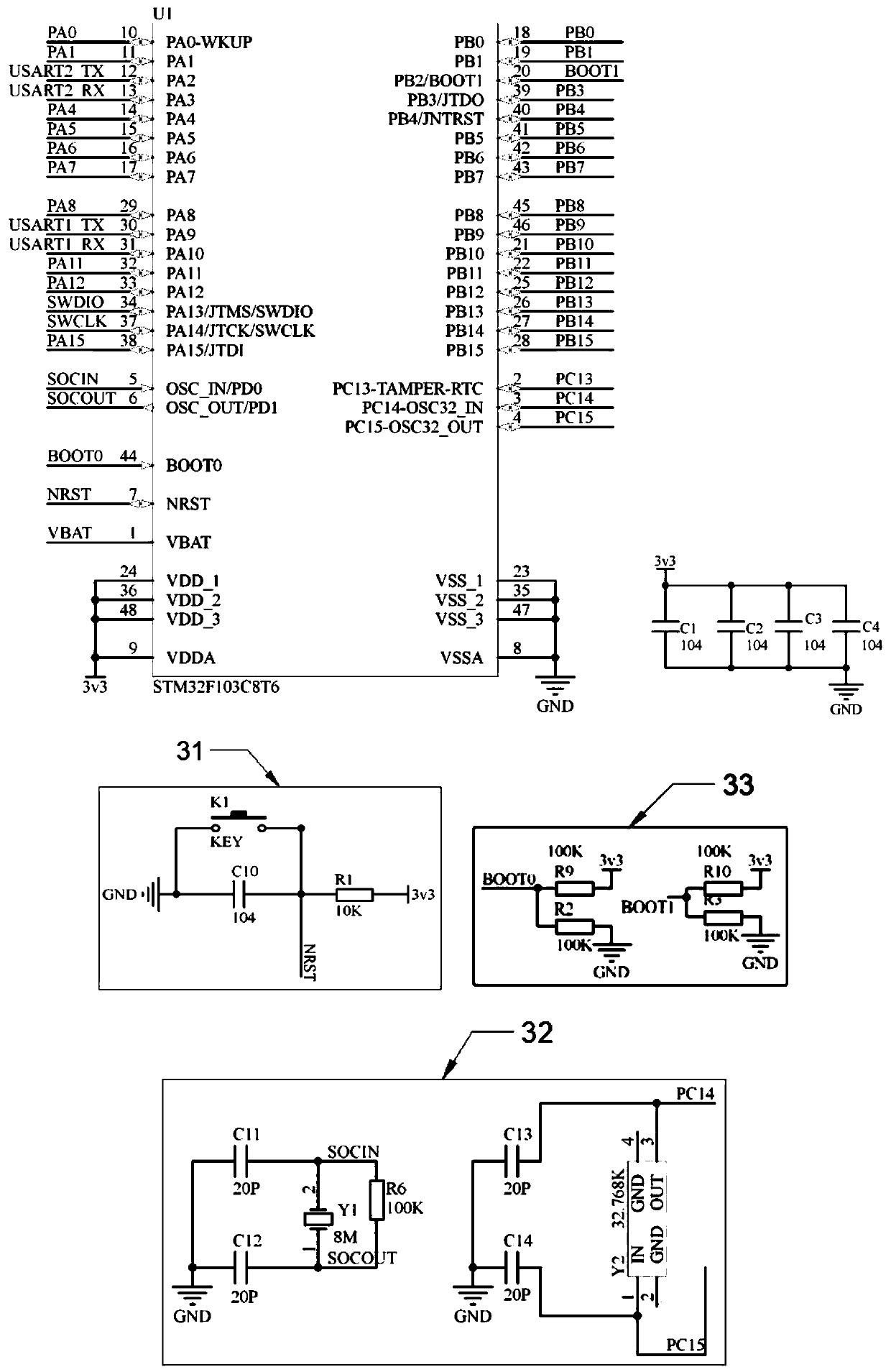

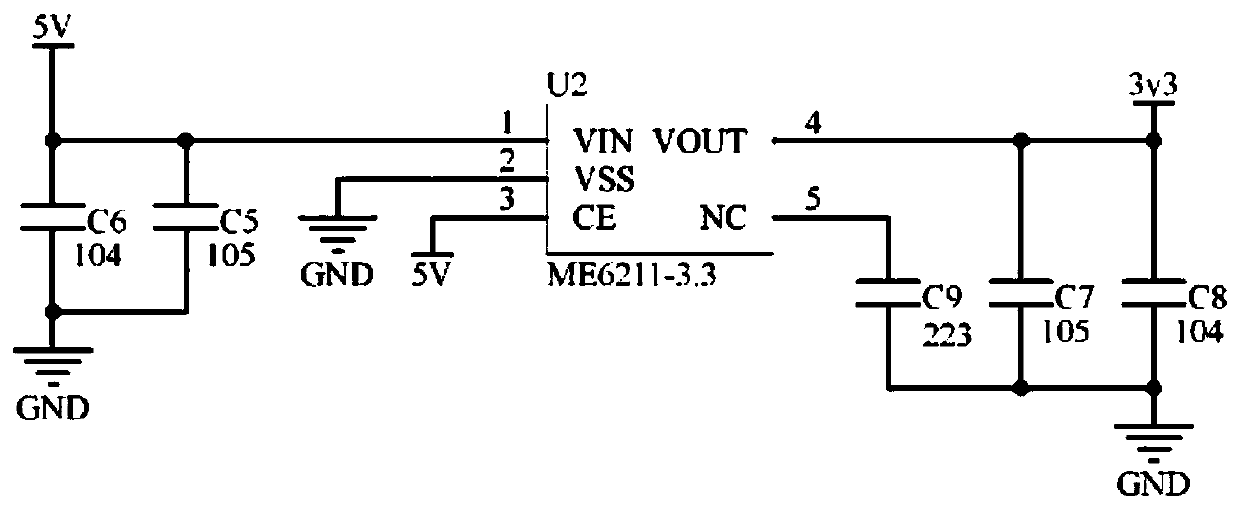

[0030] Such as Figure 1-6 As shown, a logistics equipment failure prediction terminal based on edge computing includes a power supply circuit 1, an ADC detection circuit 2, a microprocessor circuit 3, a failure indication circuit 4, and a serial port circuit 5. The input end of the ADC detection circuit 2 is connected to the output end of the sensor set on the logistics equipment to collect the operating state data of the logistics equipment, and the output end of the ADC detection circuit 2 is inputted with the data of the microprocessor circuit 3 through the ADC interface The fault indication circuit 4 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com