Forklift steering axle rear hub bearing press-fitting automation capability detection system

A forklift steering axle and rear wheel hub technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as inaccurate lubricating oil filling, tilting of bearings, mechanical errors of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

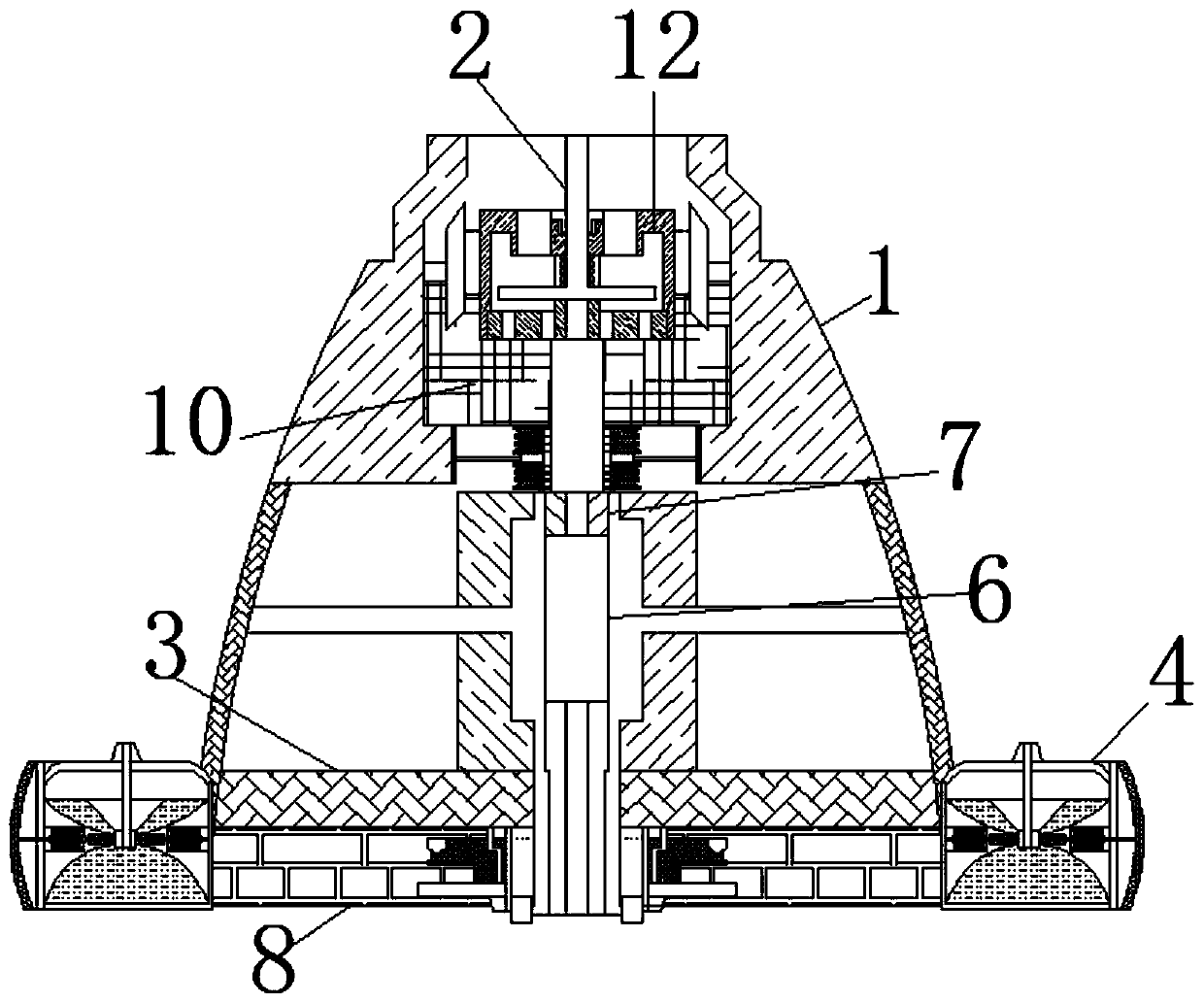

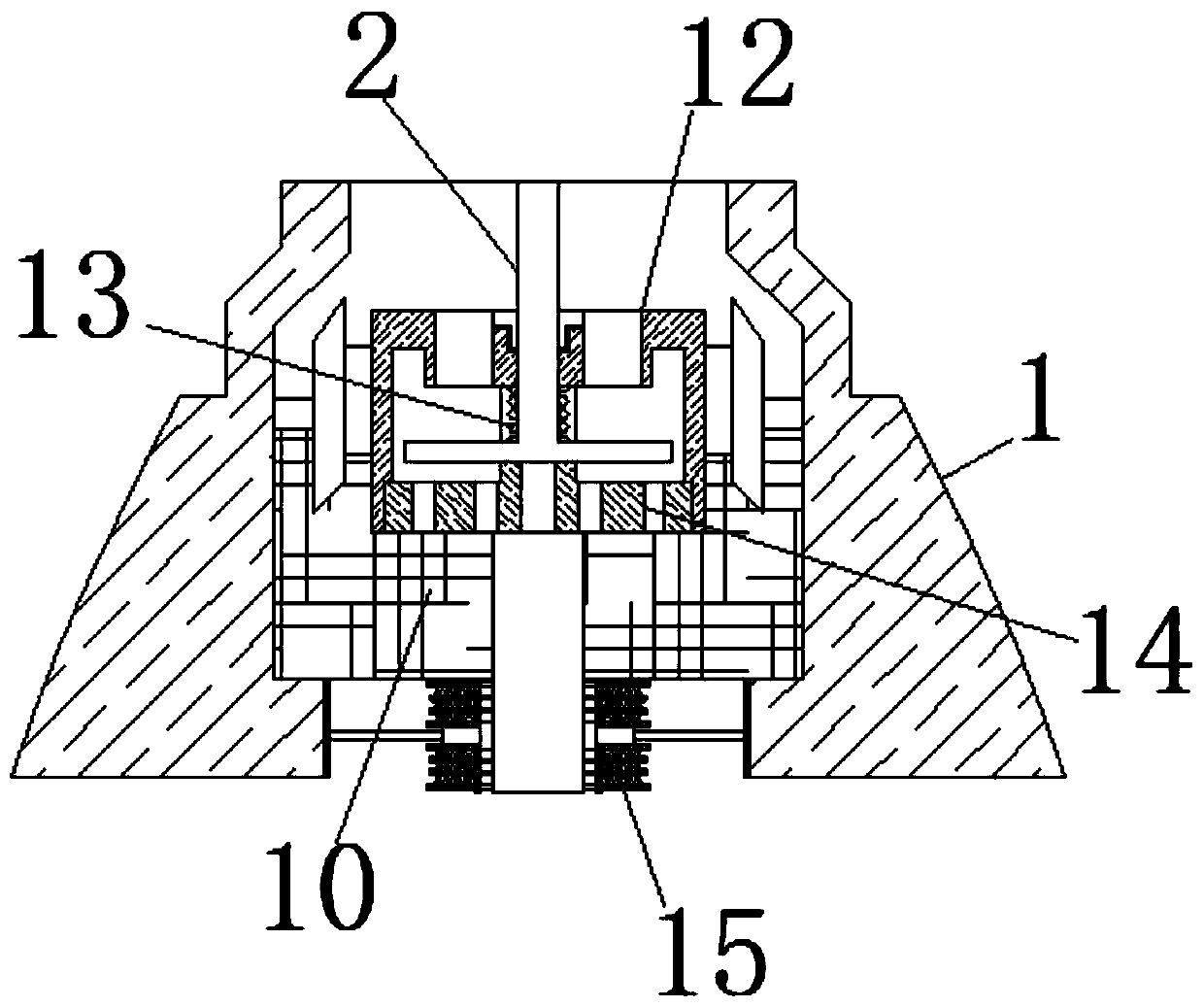

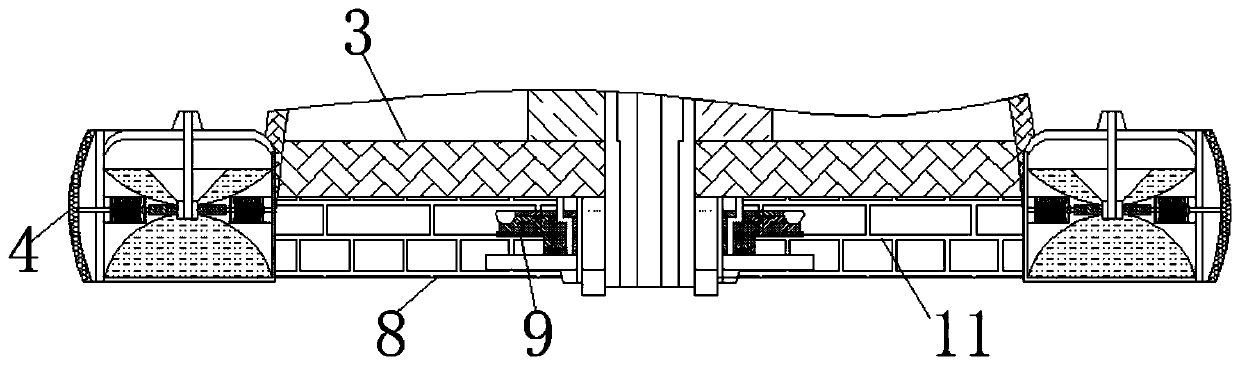

[0026] Embodiment: a forklift steering axle rear hub bearing press-fit automation device, including a housing 1, the inside of the housing 1 is movably connected with a hydraulic rod 2, the bottom of the hydraulic rod 2 is movably connected with a support plate 3, and both sides of the support plate 3 are A clamping block 4 is movably connected, and the surface of the clamping block 4 is movably connected with a compression spring 5, and a level detector 6 is fixedly installed inside the support plate 3, and the level detector 6 is a common measuring tool for measuring small angles.

[0027] In the machinery industry and instrument manufacturing, it is used to measure the inclination angle relative to the horizontal position, the flatness and straightness of the guide rail of machine tool equipment, the horizontal position and vertical position of equipment installation, etc.; it is a commonly used bubble level with a sensitivity of 0.01mm / m; An information transmitter 7 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com