CNN (Convolutional Neural Network) visualization-based PCB (Printed Circuit Board) defect detection method

A technology for PCB circuit board and defect detection, applied in image data processing, image enhancement, instruments, etc., can solve problems such as poor interpretability, and the working principle of deep neural network cannot be described in words, so as to improve generalization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

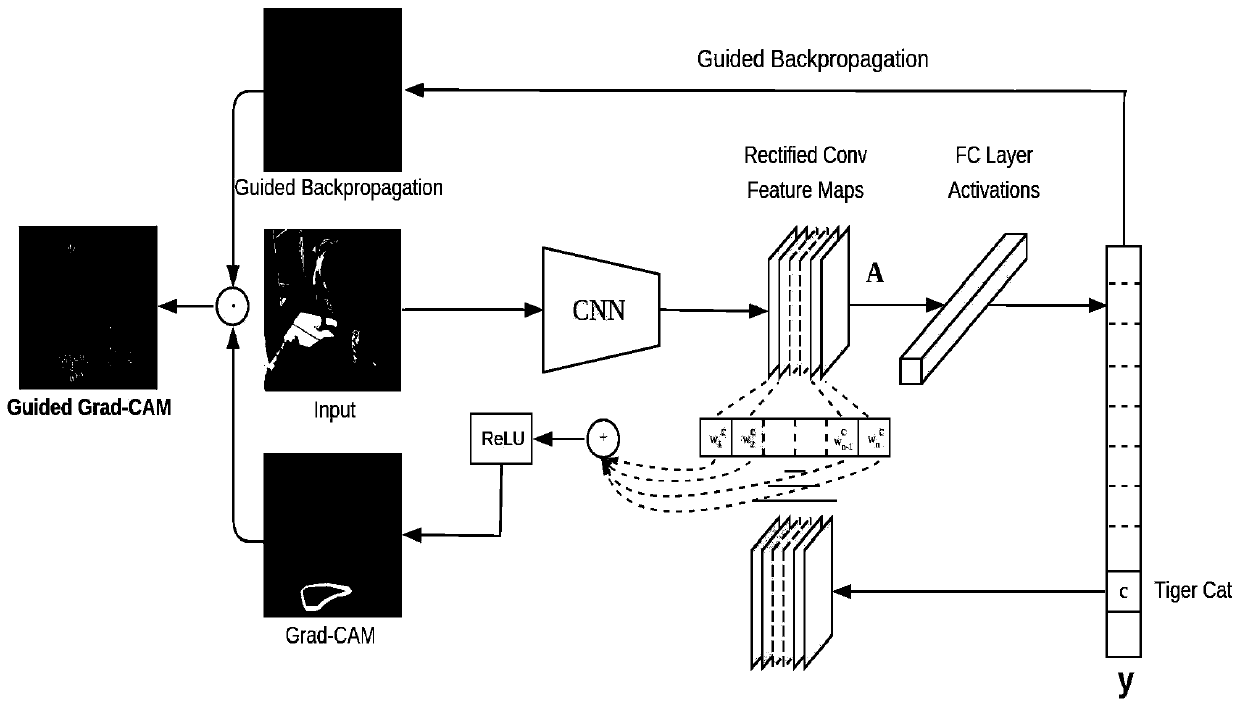

[0030] Such as Figure 1 to Figure 4 As shown, the present embodiment discloses a method for detecting defects of a PCB circuit board based on CNN visualization, and the detection method mainly includes the following specific steps:

[0031] Step S1: Collect PCB circuit board defect images and normal images, and then make training and verification data sets {(TrainX1, TrainY1), (TestX1, TestY1)} to be used for training;

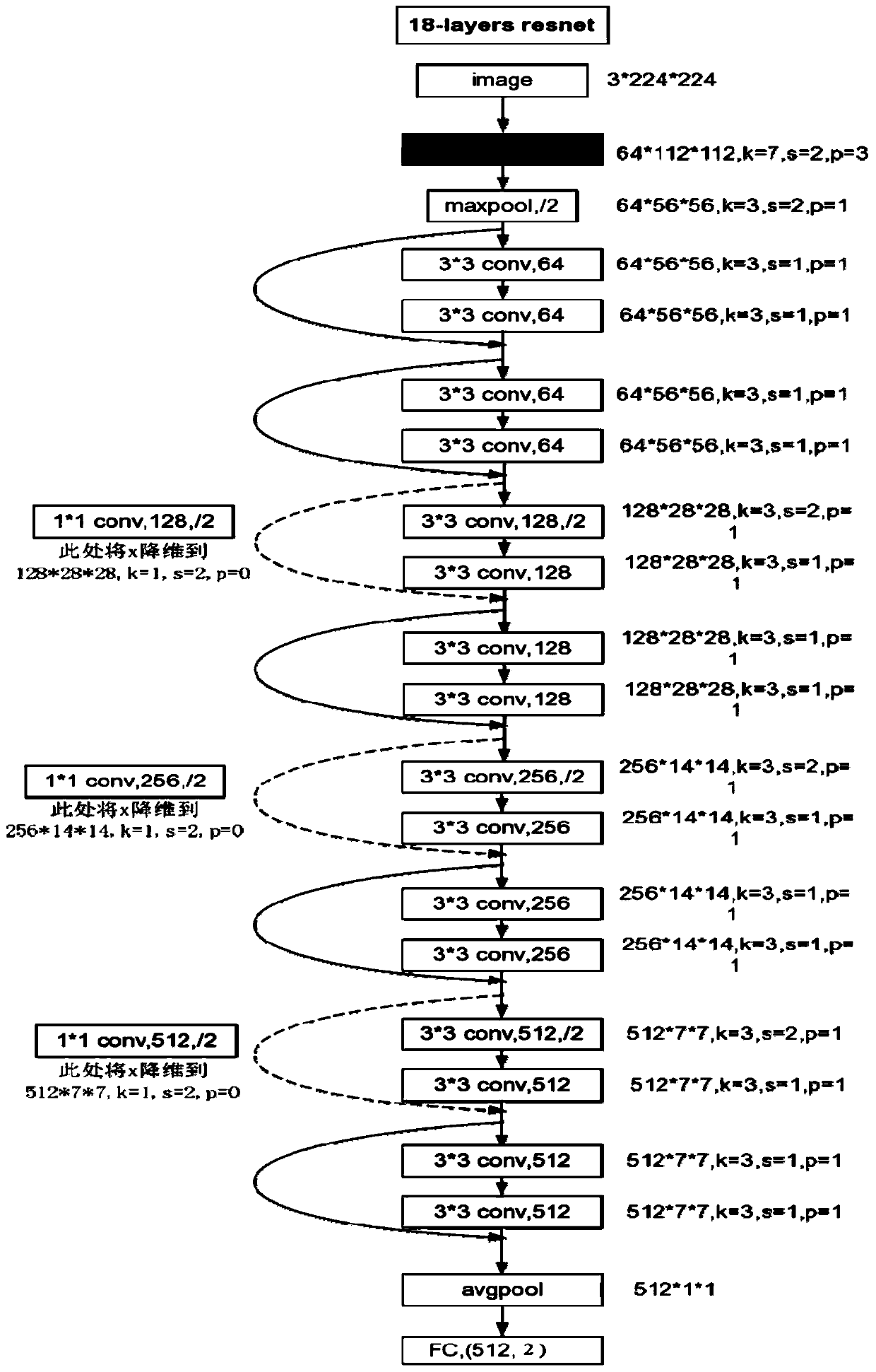

[0032] Step S2: Build a PCB circuit board defect detection and recognition model, and use the data set produced in step S1 to study circuit board defects, and obtain a preliminary recognition model Model1;

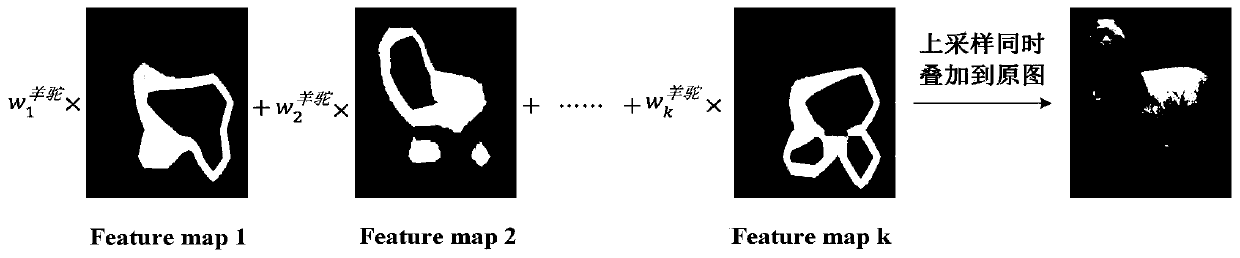

[0033] Step S3: Calculate and design the CNN visualization model (MapModel), by calculating the neuron importance weight w k , and then calculate the weighted sum of the corresponding feature map, and superimpose it on the original image after upsampling to obtain the category positioning heat map;

[0034] Step S4: Check the category positioning heat m...

Embodiment 2

[0044] This embodiment discloses a PCB circuit board defect detection method based on CNN visualization, comprising the following steps:

[0045]Step S1, collecting PCB circuit board defect images and normal images, and then making training and verification data sets {(TrainX1, TrainY1), (TestX1, TestY1)} to be used for training.

[0046] Step S2, build a PCB circuit board defect detection and recognition model, and use the data set produced in step S1 to study circuit board defects, and obtain a preliminary recognition model Model1.

[0047] Step S3, calculate and design the CNN visualization model (MapModel), calculate the weighted sum of the corresponding feature maps by calculating the neuron importance weight wk, and then superimpose on the original image after upsampling to obtain the category positioning heat map.

[0048] Step S4, check the category positioning heat map generated by the original image data through the CNN visualization model (MapModel), and check wheth...

Embodiment 3

[0064] This embodiment discloses a method for detecting defects of a PCB circuit board based on CNN visualization, which is characterized in that it includes the following implementation steps:

[0065] Step S1, collecting PCB circuit board defect images and normal images, and then making training and verification data sets {(TrainX1, TrainY1), (TestX1, TestY1)} to be used for training.

[0066] Step S1-1, use an industrial camera to capture the entire picture of the PCB circuit board on the actual production line, and then divide it into small pictures of 224×224 pixels to facilitate the identification of small defects and model training.

[0067] Step S1-2, manually mark and classify the divided 224×224 pictures, divide them into defective and non-defective categories, and ensure the balance of the data. The data volume of the two categories is 1:1, and then the data According to 9:1, it is divided into two parts, the more data is used as the training set (TrainX1, TrainY1),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com