Display substrate, display device and manufacturing method thereof

A display substrate and manufacturing method technology, applied in identification devices, organic semiconductor devices, instruments, etc., can solve problems such as box thickness, light leakage, and affecting display effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

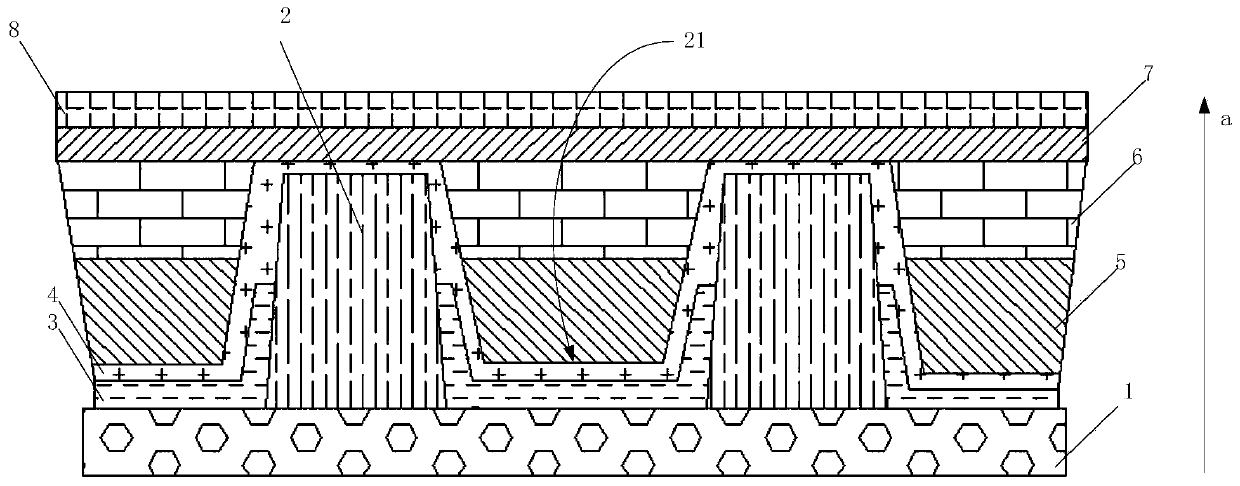

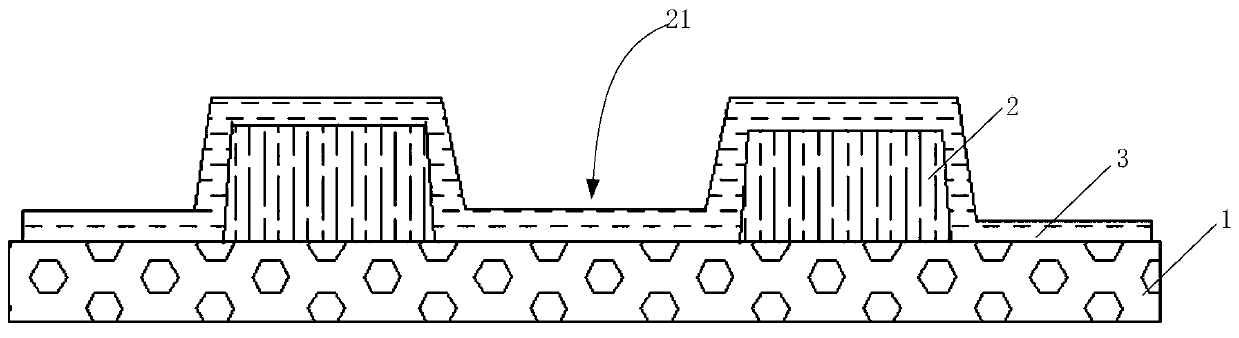

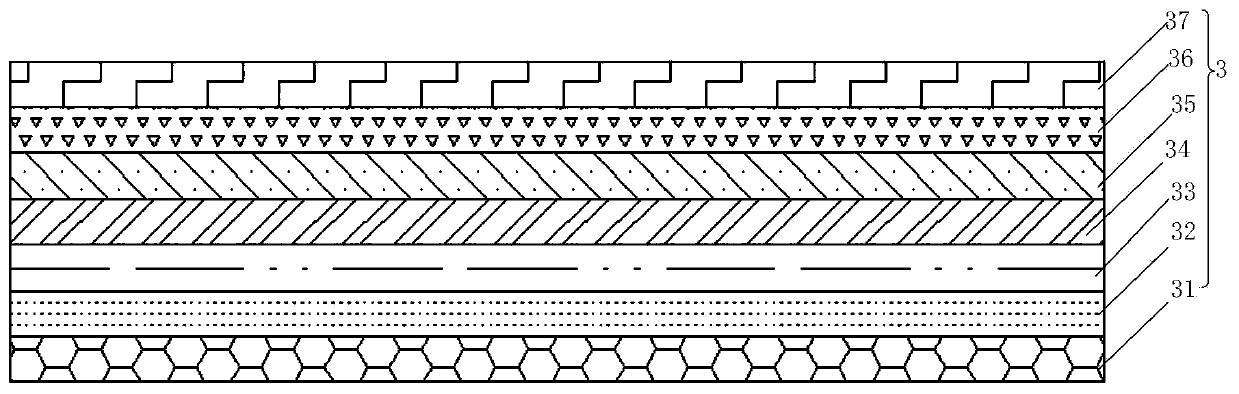

[0041] Reference attached figure 1 , the display substrate provided by the embodiment of the present invention, which includes a TFT substrate 1, a pixel defining layer 2, an electroluminescent device layer 3, a connection layer 4, a first encapsulation layer 5, and a quantum dot layer 6; the pixel defining layer 2 is set On the TFT substrate 1, and surround several pixel pits 21;

[0042] Each of the pixel pits 21 is sequentially stacked with an electroluminescent device layer 3, a connection layer 4, a first encapsulation layer 5, and a quantum dot layer 6, and the connection layer 4 in the adjacent pixel pit 21 is The side of the pixel defining layer 2 that is away from the TFT substrate 1 is in contact with each other, and is used for electrically connecting the electroluminescent device layers 3 in two adjacent pixel pits 21 .

[0043] Specifically, in order to solve the problem that when quantum dots are applied in flexible OLED display devices, the conventional box-ali...

Embodiment 2

[0063] Further, an embodiment of the present invention provides a display device, which includes the display substrate described in the above embodiments.

[0064] It can be understood that, the display substrate in this embodiment can directly use the display substrate described in Embodiment 1, and its detailed structure can refer to the content of the above embodiment.

Embodiment 3

[0066] Reference attached Figure 4 , an embodiment of the present invention provides a method for manufacturing a display substrate based on Embodiment 1, which includes the following steps:

[0067] 101. Making a TFT substrate 1;

[0068] Specifically, it is not difficult for those skilled in the art to fabricate a thin film transistor (TFT) circuit on a base substrate according to the conventional technology, so details will not be repeated here.

[0069] 102. Fabricate a pixel defining layer 2 on the TFT substrate 1, and surround several pixel pits 21;

[0070] Specifically, a directional thermal expansion material is selected as the pixel defining layer 2, and the pixel defining layer 2 is fabricated on the TFT substrate 1 by inkjet printing, and several pixel pits 21 are formed.

[0071] 103. Arranging an electroluminescent device layer 3 on the side of the pixel defining layer 2 away from the TFT substrate 1;

[0072] Specifically, the electroluminescent device layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com