Telescopic adjustable bag cage of bag type dust collector

A bag-type dust collector, telescopic adjustment technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as inconvenient replacement and maintenance, shortening the length of the bag cage, affecting the strength and stiffness of the bag cage, etc. , to prevent deformation and damage during transportation, facilitate on-site disassembly and assembly operations, and improve the utilization rate of bag cages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

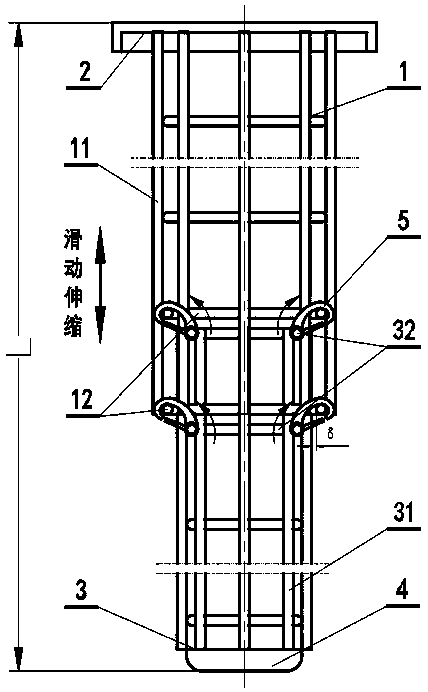

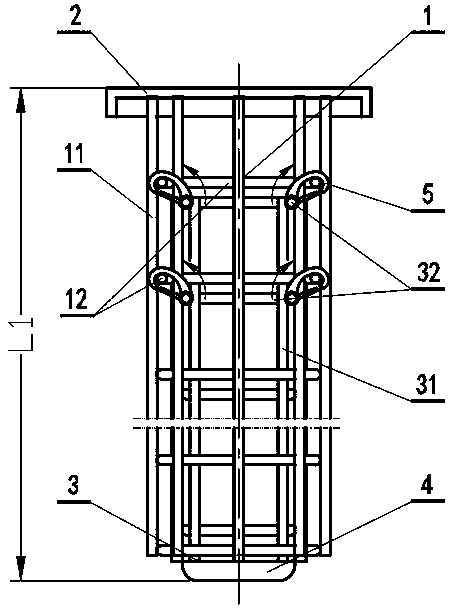

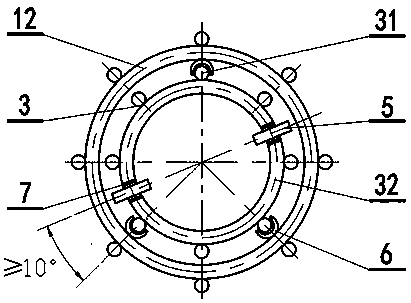

[0030] The present invention will be further described below in conjunction with accompanying drawings and examples of implementation.

[0031] The present embodiment takes the bag cage of 8 vertical ribs as an example.

[0032] A retractable and adjustable bag filter bag cage, comprising an outer cage 1, a top bowl of the bag cage 2, an inner cage 3, a bottom bowl of the bag cage 4, a lock hook 5, a guide ring 6, a limit mechanism 7 and an outer cage Parts such as vertical rib 11, outer cage anti-brace ring 12, inner cage vertical rib 31, inner cage anti-brace ring 32. The cage top bowl 2 is welded to the top of the outer cage 1, and the vertical ribs 11 of the outer cage are welded vertically to the outer cage counter support ring 12 and the cage top bowl 2, and are uniformly distributed along the outer profile of the horizontal section of the outer cage 1 in the circumferential direction. Arrangement, the spacing is 30-50mm; the outer cage anti-brace ring 12 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com