Novel soldering equipment and welding method thereof

A technology of soldering and equipment, which is applied in new soldering guns and new welding fields, can solve problems such as hand injuries, and achieve the effects of simple structure, simplified welding methods and welding steps, and humanized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

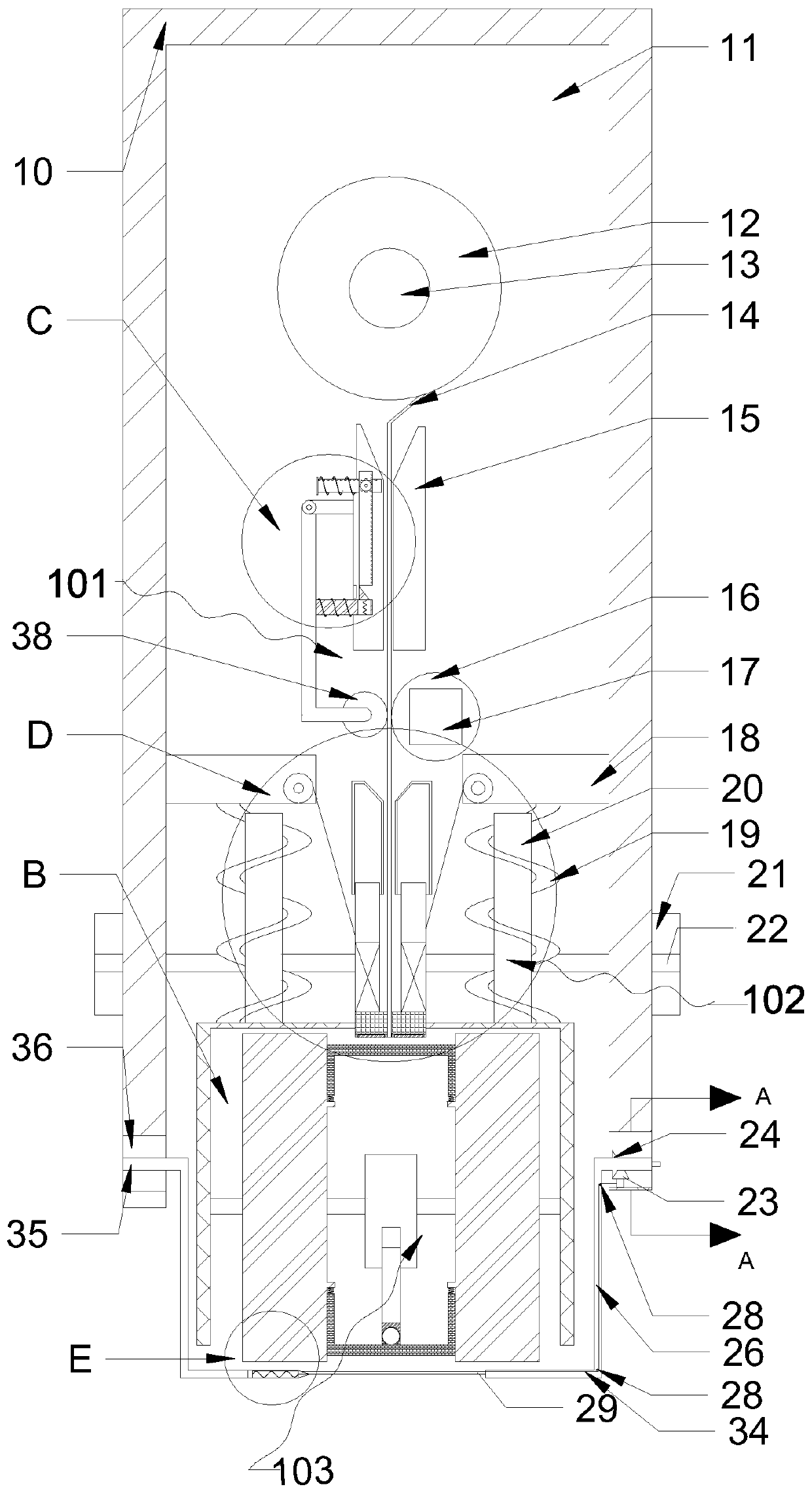

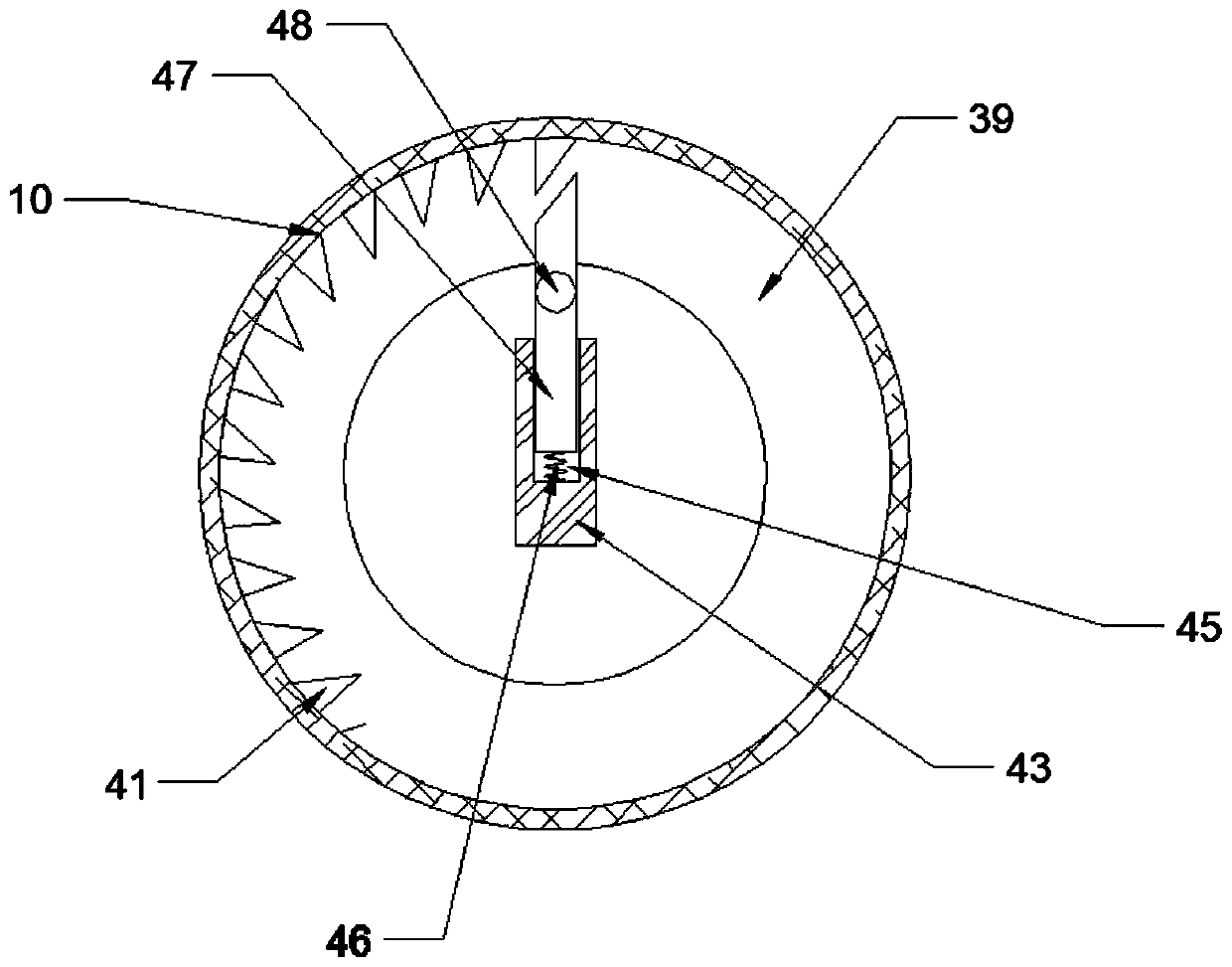

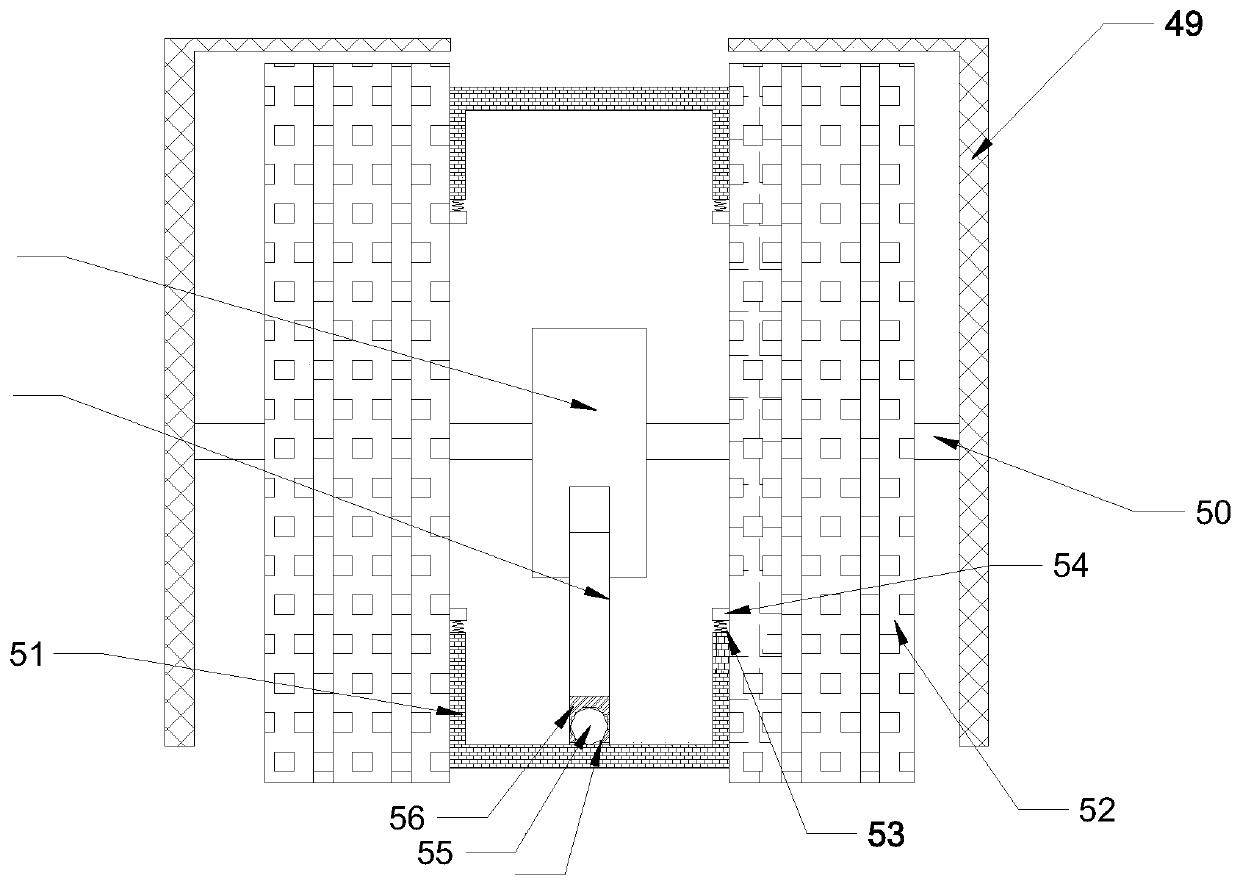

[0017] Such as Figure 1-6 As shown, a new type of soldering equipment includes a housing 10, a placement chamber 11 arranged in the housing 10, a support plate 18 fixedly arranged at the four end walls of the placement chamber 11, and a feeding device fixedly arranged above the support plate 18. 101, the lifting device 102 fixedly arranged under the support plate 18, two spring assemblies fixedly arranged on the lower end surface of the support plate 18, the spring assembly includes a large spring 19 symmetrically arranged on the lower end surface of the support plate 18, fixedly arranged on the large spring assembly The welding device 103 below the spring 19, the welding device 103 includes a heat shield 49 fixedly arranged on the lower end surface of the large spring 19, an intermediate shaft 50 fixedly arranged on the left end surface of the heat shield 49, and rotatably sleeved on the intermediate shaft 50 The heat insulation wheel 52 is fixedly arranged on the step wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com