Drum material digital printing double-shaft and double-station deploying and retracting automatic switching coiling machine

A digital printing and automatic switching technology, which is applied in printing, printing devices, winding strips, etc., can solve the problems of unmatched single-release and single-receipt, reduced operation process, and low running speed, so as to improve printing quality and ensure reasonable Layout, the effect of increasing printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

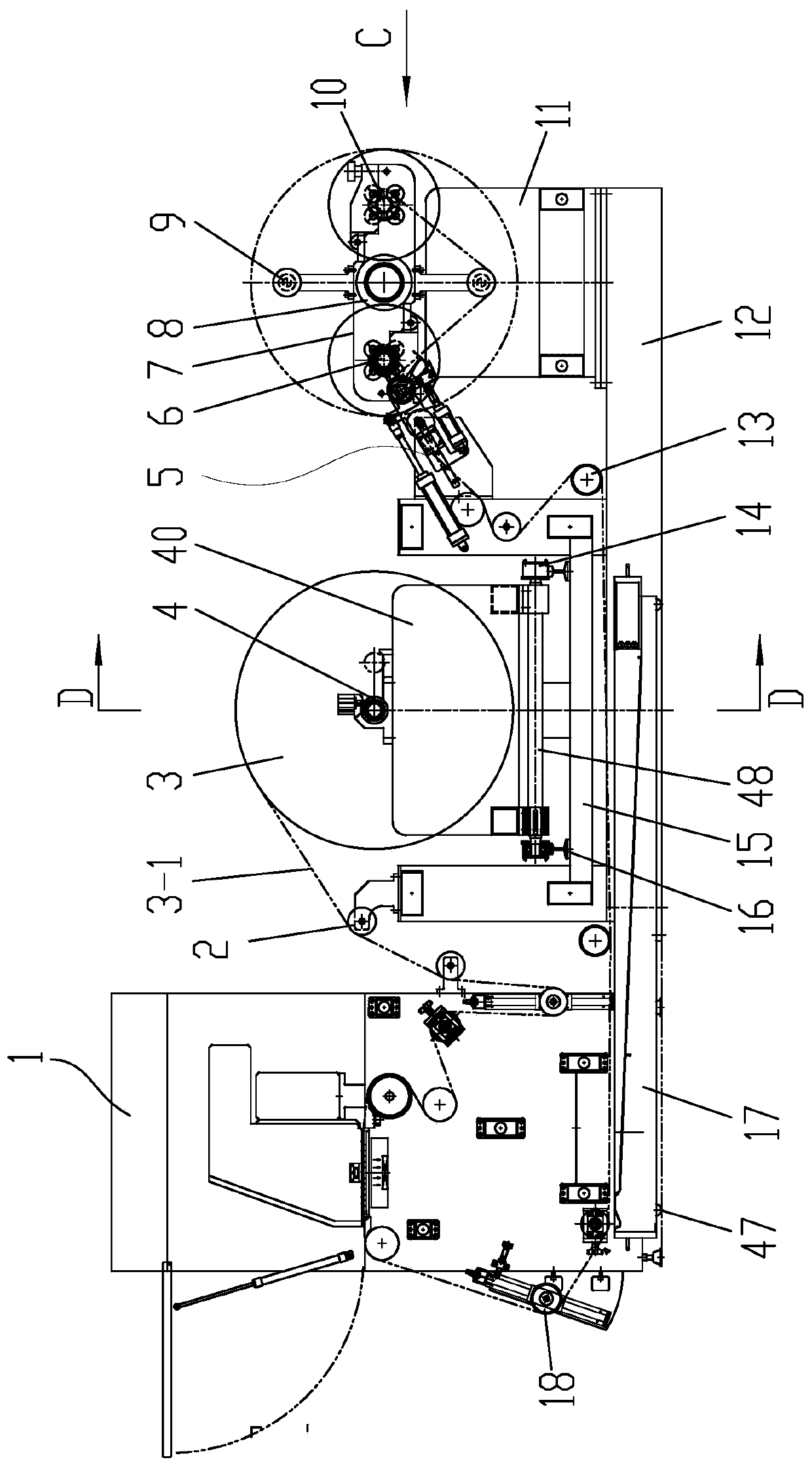

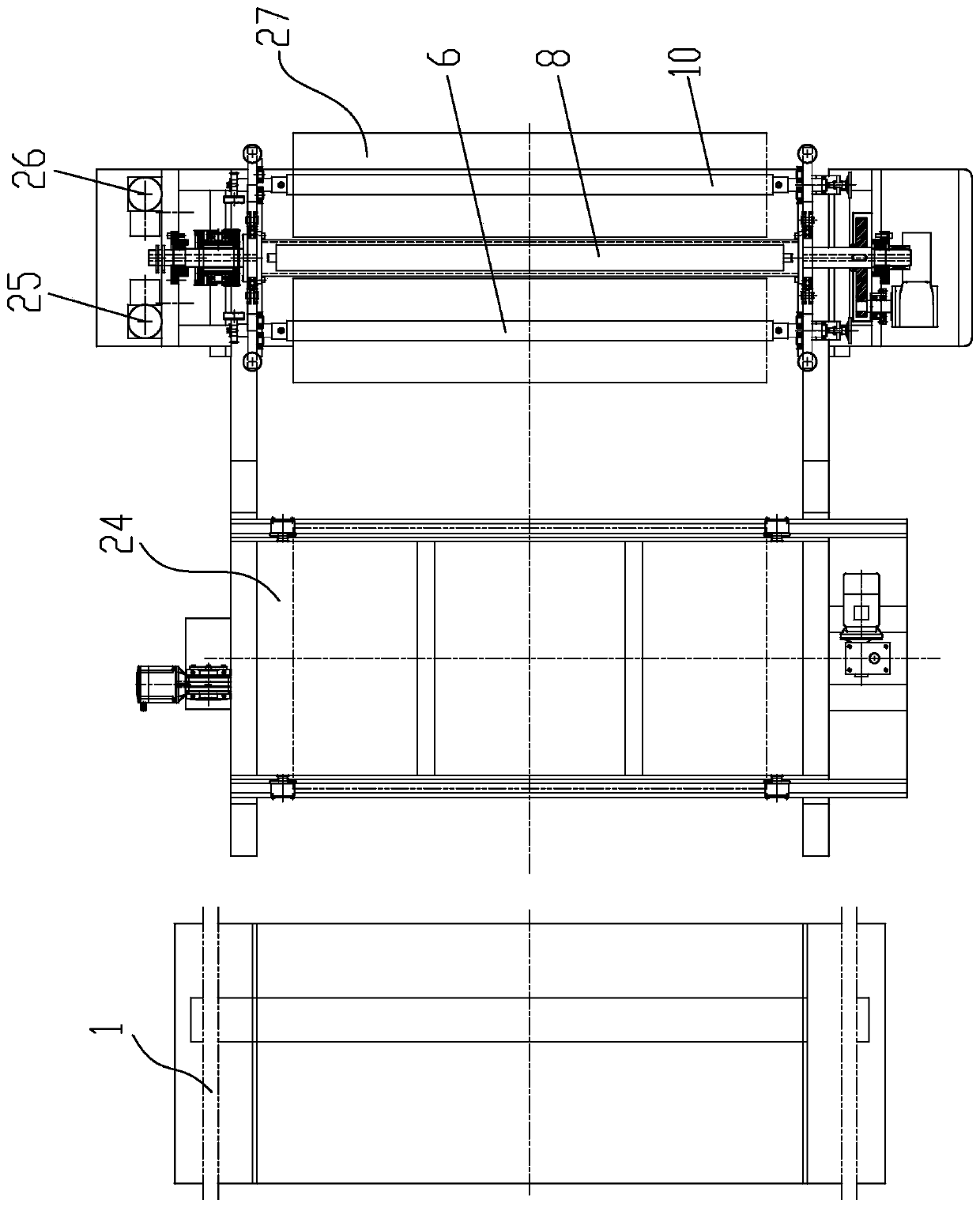

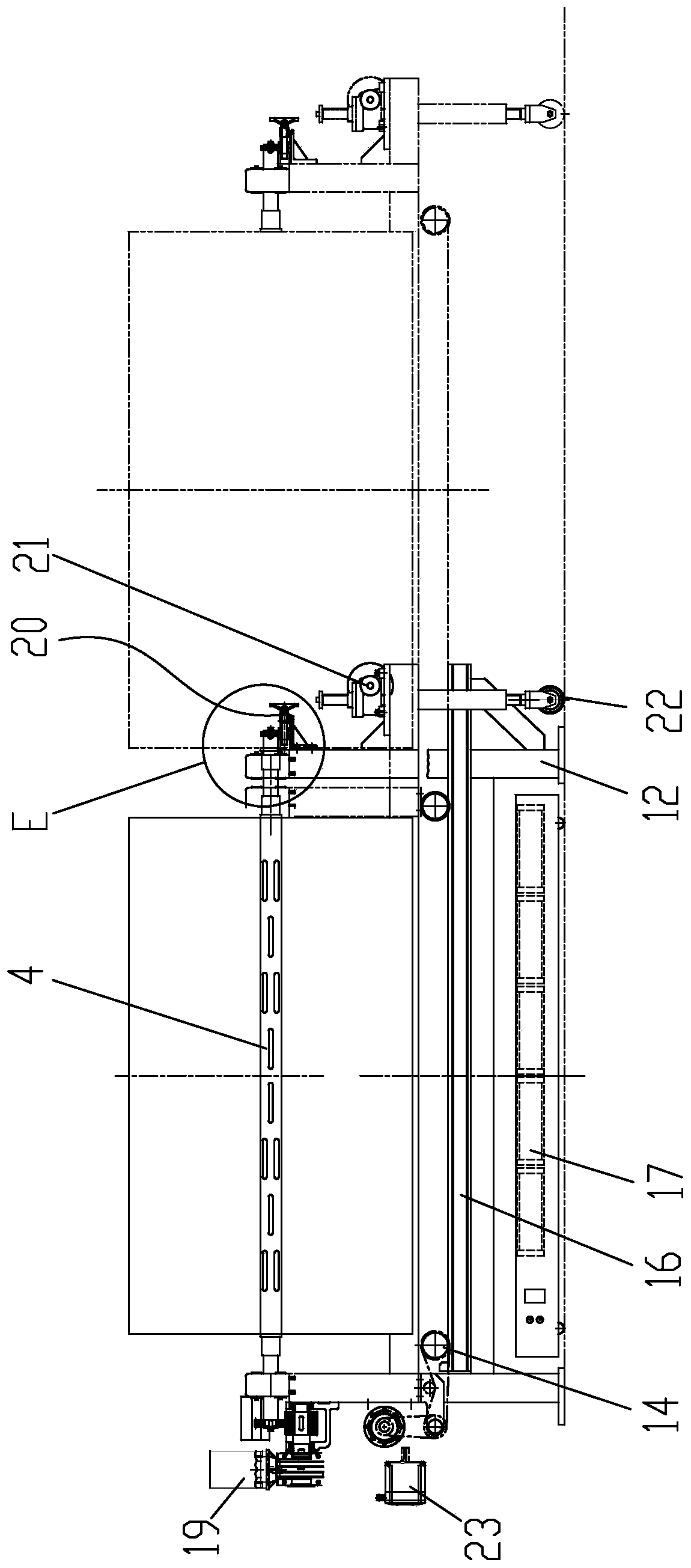

[0033] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0034] For the convenience of description, the figure 1 The left side of is left, the right side is right, figure 1 The inward direction of the vertical paper is the back, and the outward direction of the vertical paper is the front.

[0035] Such as figure 1 , figure 2 The shown roll material digital printing double-axis double-station retractable automatic switching coiler includes a frame 12, a digital printing station, a retractable station and a drying box 17. The frame is horizontally fixed on the ground, and the lower part of the frame penetrates along the left and right directions. The digital jet printing station and the loading and unloading station are all installed on the frame; wherein, the digital jet printing station is provided with a digital inkjet printing machine 1 (conventional equipment, which can be obtained by outsourcing), so that ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap