Martensitic stainless steel surface hardening agent as well as preparation method and application method thereof

A martensitic stainless steel, application method technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problem that the surface hardness can not meet the wear resistance requirements, it is difficult to meet the high wear resistance, etc. Little change in hardness, effect of increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

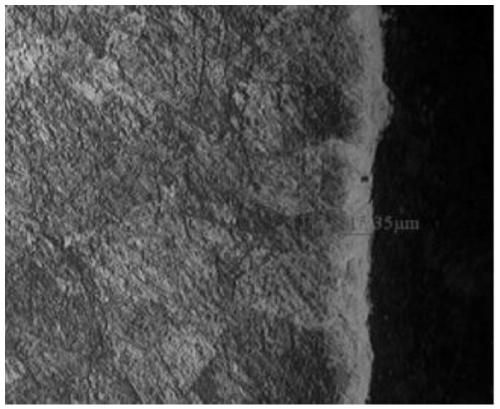

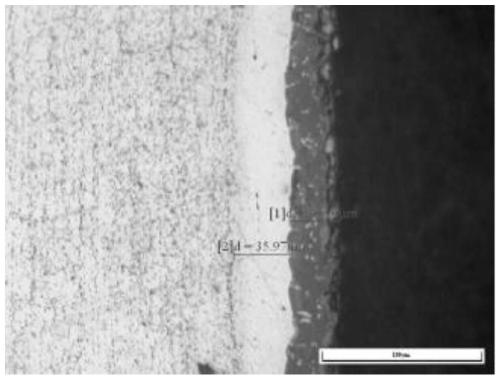

Image

Examples

Embodiment 1

[0038] Embodiment 1: A surface hardener for martensitic stainless steel, calculated in parts by weight: 20-30 parts of borax molten salt, 10-16 parts of boron powder, and 5-8 parts of carbon quantum dots.

[0039] The preparation method of martensitic stainless steel surface hardener comprises the following steps

[0040] S1 mixing carbon quantum dots and borax molten salt to obtain mixture A;

[0041] S2. Add boron powder to the mixture A to obtain a surface hardener for martensitic stainless steel.

[0042] The surface hardening method for martensitic stainless steel of the present embodiment comprises the following steps:

[0043] A1. Clean the martensitic stainless steel to remove surface oil and impurities;

[0044] A2. Place the martensitic stainless steel matrix in a high-temperature martensitic stainless steel hardener, and the metal ions in the borax molten salt react with the carbon and nitrogen atoms in the martensitic stainless steel matrix to diffuse in the mart...

Embodiment 2

[0051] Embodiment 2: A surface hardener for martensitic stainless steel, calculated in parts by weight: 20 parts of borax molten salt, 10 parts of boron powder, and 5 parts of nitrogen-doped carbon quantum dots.

[0052] The preparation method of martensitic stainless steel surface hardener comprises the following steps

[0053] S1. Preparation of carbon quantum dots: using citric acid chloride as carbon source and polyethyleneimine as nitrogen-doped molecules for molecular curing;

[0054] S2. Mix and stir the carbon quantum dots and borax molten salt to obtain a mixture A;

[0055] S3. Add boron powder to the mixture A to obtain a surface hardener for martensitic stainless steel.

[0056] The surface hardening method for martensitic stainless steel of the present embodiment comprises the following steps:

[0057] A1. Clean the martensitic stainless steel substrate to remove surface oil and impurities;

[0058] A2. Place the martensitic stainless steel substrate in a high-...

Embodiment 3

[0065] Embodiment 3: A surface hardener for martensitic stainless steel, calculated in parts by weight: 30 parts of borax molten salt, 10 parts of boron powder, and 8 parts of carbon quantum dots.

[0066] The preparation method of martensitic stainless steel surface hardener comprises the following steps

[0067] S1. Preparation of carbon quantum dots: using citric acid chloride as carbon source and polyethyleneimine as nitrogen-doped molecules for molecular curing;

[0068] S2. Mix and stir the carbon quantum dots and borax molten salt to obtain a mixture A;

[0069] S3. Add boron powder to the mixture A to obtain a surface hardener for martensitic stainless steel.

[0070] The surface hardening method for martensitic stainless steel of the present embodiment comprises the following steps:

[0071] A1. Clean the martensitic stainless steel substrate to remove surface oil and impurities;

[0072] A2. Place the martensitic stainless steel matrix in a high-temperature marten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com