Snow removal forklift

A snow shovel and bucket technology, applied in the field of snow removal machinery, can solve the problems of ice surface asphalt turning, hydraulic cylinder piston jamming, thickening and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

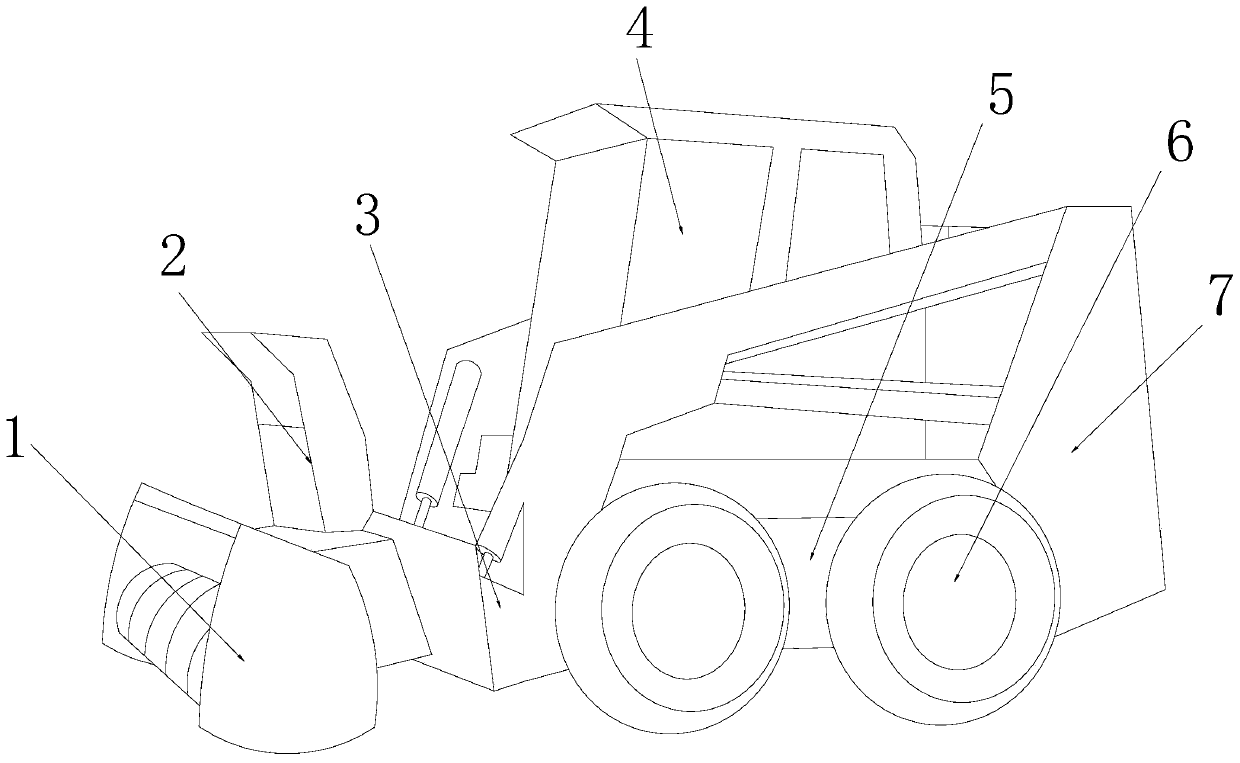

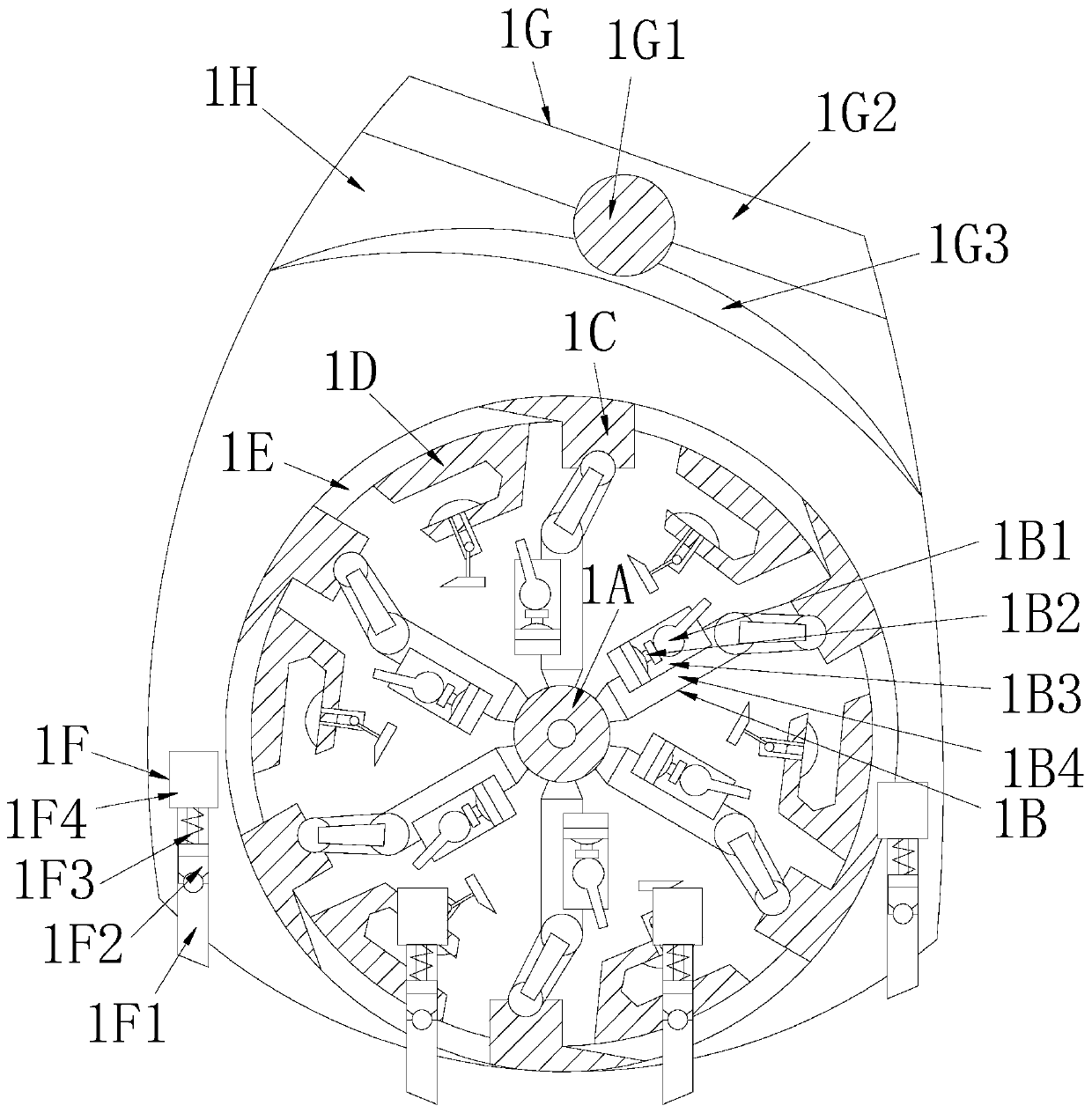

[0032] see Figure 1-Figure 6, the present invention provides a kind of snow plowing forklift, and its structure comprises: Spiral cutter barrel bucket 1, auxiliary pressure folded plate column 2, hydraulic rod frame 3, driver's cab 4, vehicle chassis seat 5, rubber moving wheel 6, motor Rear carriage 7, the spiral knife barrel bucket 1 is installed on the lower left corner of the auxiliary pressure folding plate column 2, the spiral knife barrel bucket 1 is nested on the left side of the hydraulic rod frame 3, and the hydraulic rod frame 3. The chassis base 5 is mechanically connected to the motor rear box 7. The cab 4 is inserted on the top surface of the chassis base 5 and is perpendicular to each other. The chassis base 5 is mechanically connected to the rubber moving wheel 6. Spiral knife barrel bucket 1 is equipped with shaft wheel body 1A, salt injection bomb sprinkling barrel 1B, swing lever blade seat 1C, wrapping pressure lining clamp seat 1D, spiral knife ring frame...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a kind of snow removal shovel, other respects are identical with embodiment 1, and difference is:

[0040] see figure 2 , the splash-proof pressure plate seat 1G is composed of a shaft support clip hanging wheel 1G1, an inclined frame top plate 1G2, and a crescent cover pressure plate 1G3. The shaft support clip hanging wheel 1G1 is nested under the bottom of the middle section of the inclined frame top plate 1G2, and the crescent The cover pressing plate 1G3 is mechanically connected with the shaft support clip hanging wheel 1G1, and the crescent cover pressing plate 1G3 is swung by the shaft support clip hanging wheel 1G1 to form the slicing anti-splash effect of thickening and inputting the inclined snow layer.

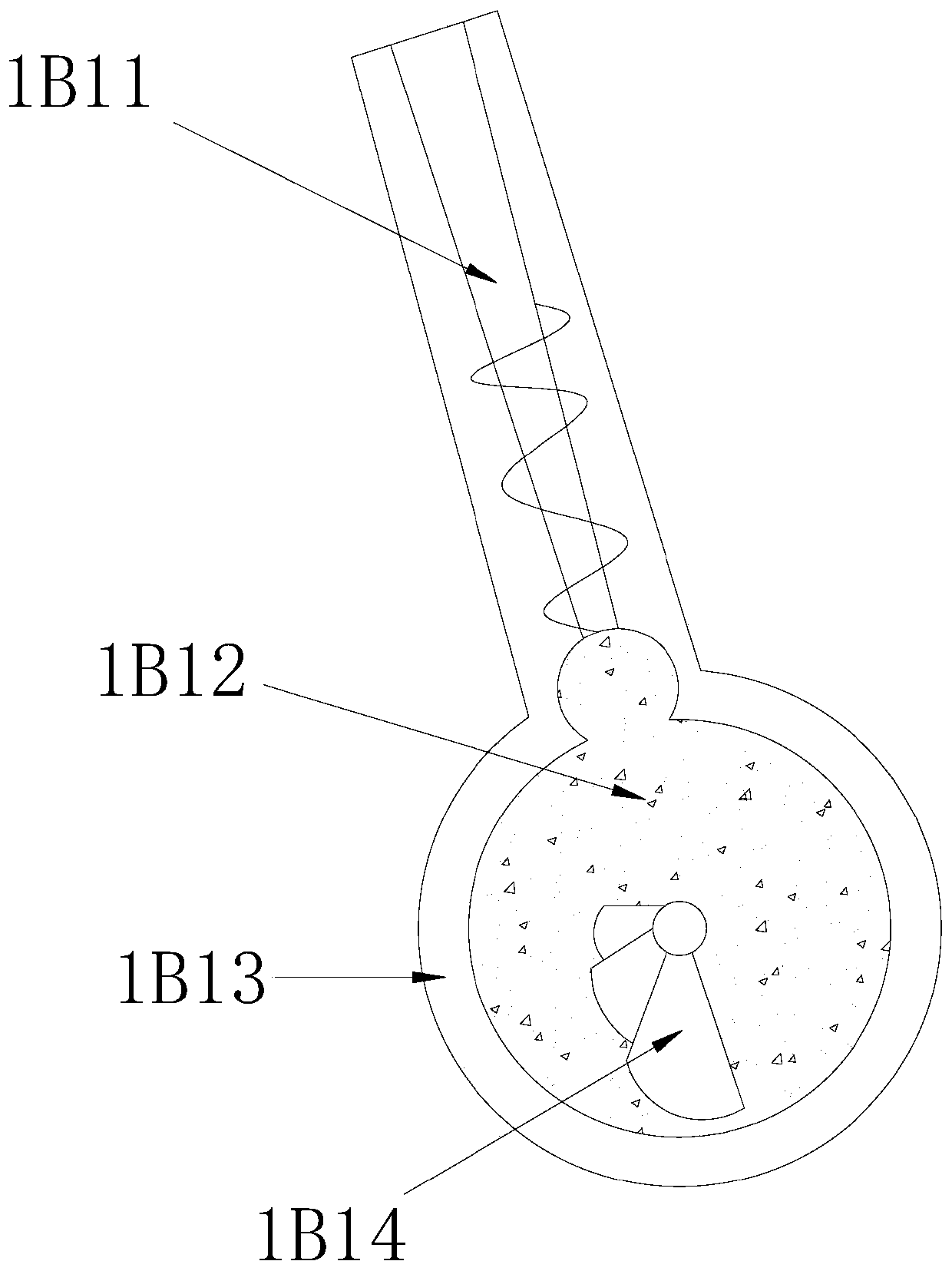

[0041] see Image 6 , the shaft support clip hanging wheel 1G1 is composed of flap counterweight 1G11, shaft clip support wheel frame 1G12, clip plate 1G13, lining block hanging wheel groove 1G14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com